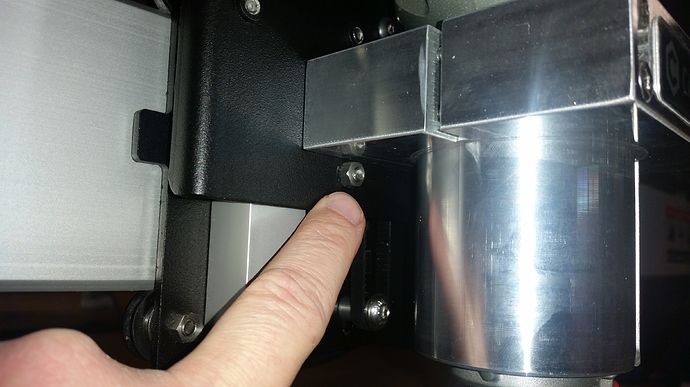

I have, what seems significant to me, right movement at the lower Z carriage wheels. I don’t recall it being loose when I assembled. Today I ran my first test job on a piece of construction plywood. Towards the end of the job, when the spindle was moving left I noticed the bit kicking to the right and when going around a curve moving to the rear the bit would drag behind. After inspecting I noticed the nut on the lower left Z carriage wheel was very loose. I tightened it but there is still a good bit of movement. Is this normal? I’ll attempt to load a pic and video.

Please see: http://docs.carbide3d.com/support/tensioning-eccentrics/

If that doesn’t square things away, let us know at support@carbide3d.com and we’ll do our best to help you puzzle this out.

Thanks William. I must have missed this section in the assembly instructions. Thanks for the help.

Followed the procedure in the video, that was absolutely the fix. Thanks again for the help William!

Last night the lower, left v-wheel on the z carriage fell off my Shapeoko XXL. Thankfully it was not during operation, it happened when I was troubleshooting the X-axis limit switch not being able to engage and noticed a significant amount of play in the z carriage. I wanted to see if there is an issue specifically with the lower left v-wheel on the z carriage?

There shouldn’t be an issue with a specific V wheel — you should always check them though: https://docs.carbide3d.com/general-faq/machine-operating-checklist/

and if you have one which often loosens up consider removing it, putting a thin bead of thread lock along the length of the threads, then reinstalling once dry — that should provide sufficient resistance to hold things in place.