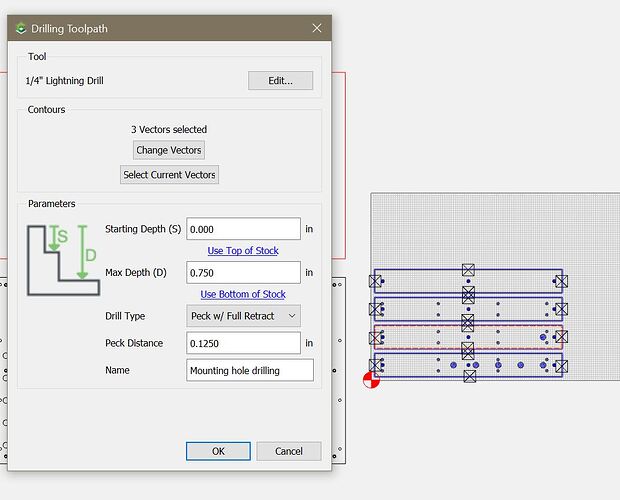

After Downloading “AmericanRevival” file from "https://cutrocket.com/p/651c7dfd9e119 and reviewing the tool paths I came across a bit I am unfamiliar with, Could anyone please direct me to the exact endmill that is being refereed to in the attached picture…

I would suggest contacting the person who uploaded that.

That said, be very cautious of tooling in the machines — make sure that any tool which is used is rated to be spun at the speeds which it will be used at (with a reasonable safety margin) — most drill bits are rated for hundreds of RPM at most.

Hi thanks for the replay, I review all files before loading the project into my machine. I want to make sure I have exact bits and check depts, feeds and speeds… I like a slower cut vs a fast cut… not using this file until I get a better idea on what a lightening bit is…

thanks again.

Most likely it is this:

IDC calls this series of bits Lightning.

thank you very much I really appreciate the response.

v/r

CNC machines make poor drills. So if you have a 1/4" or smaller router bit that will cut .75" then you could increase the pocket size to .26" and use a regular end mill.

Drilling with a CNC is hard to do because drilling requires speeds of the router slower than most can go. It is possible but takes specialized cnc drill bits which are more expensive than what you likely already have. You just increase the 1/4" holes slightly and a regular 1/4" bit will cut the pockets just fine. Use an upcut if you have one because a down cut pushes the chips deeper into the hole you are creating.

basically anything over 3/32 shouldn’t be done on our machines if i remember the math, in aluminum that is, using a vfd.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.