My first sign on new build using vcarve vbit.

Can’t figure out how to get a clean v but still pretty happy with result.

I see that my cnc is not level so any advise on calibration would be appreciated.

Plus clean v bit grooves.

Very nice! Great looking piece.

looks great, did you only use one milling bit to do this?

Very nice! Looks great.

One thing that I found when using a V-bit is fast feed rates. I, generally, use a 3/16" 30 or 60 degree bit. My feed rates vary depending on the material, but are in the 60-75 IPM. Just my take on the situation.

I used one 90 deg v bit.

Thank you for your feedback and advise.

Is there any chance you can upload the design file? Keen to see how it looks in CAD/CAM - I have only played with flat bits currently.

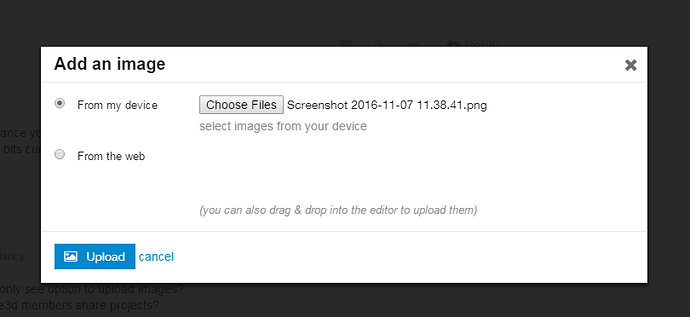

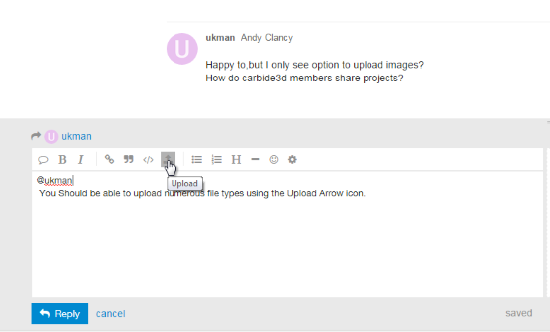

Happy to,but I only see option to upload images?

How do carbide3d members share projects?

The forum allows you to upload a zip. It looks really good!

@ukman

You Should be able to upload numerous file types using the Upload Arrow icon.

Then choose your file, there are size limitations, so you may have to zip it.

compass rose.zip (832.3 KB)

attached svg & vcarve 6 file.

To get a clean cut, I’ve often run the job twice…

after the 1st run has finished, drop z 0.2mm below 0, reset z to 0 and rerun the job.

Ok, the carvings will be ever so slightly wider but you get a nice clean cut…

Why not make the initial run w/ the Z-axis set 0.2mm too high, then lower the Z by 0.2 after the first run?

Looks good. Wow. Great job.

Gents you are awesome.

I took your advise and went nuts.

I did learn that using a better quality wood makes a huge difference.

Poplar was so so after some work removing fuzzies.

Cherry and cedar required zero cleanup

1st pic is cedar, 2nd pic cherry and 3rd is poplar.

The cherry and cedar came out so well I am afraid to paint them.

I may just use tung oil.

I am open to suggestions.

Thanks again for all your help.

Andy