I get that z probing is more important, and know why. I thought that it was fairly basic for CNC routers, and that the point of the X/Y/Z probe was to… probe all 3. So asking for additional functionality is the point of a request.

And yes, at this day and age of $100 g code controlled machines, that move everything from bic pens to laser beams, especially when most of those machines do one or 2 things more than this, is not a crazy amount of expectation.

Heck, you think I asked for the thing to be compatible with a 4th axis or indexing table out of the box.

Hand feeding? I saw links to how to’s, that I already had looked at, and didnt apply, and wikis that didnt have info relevant to what I was trying to do, as well as saying that you can use a different control software, and appears the be more prototype than functional, and requires a lot of manual coding.

Here Im looking for 2 simple things, flipping the sensor (one of the features I bought it for since it was sold as an XYZ probe,and sold as one of the big features, as well as seeming to be in demand).

I get the price point. Its not a 14K shopbot. Maybe my requests come off as bitching. That isnt the intent. I know its not a laser… its got similar functionality (moves X, Y, and Z, and at least one of my lasers has auto probing, but not used) and uses a control suite to translate vector info into gcode to move stepper motors. Ive got 2 of them, one heavily modified from something sustainable as a medium duty business use machine. So thats my experiance for the last 4 years when it comes down to similar equipment,a nd what I base my use on. I dont expect either of them to have the functionality of the high dollar machines I learned on originally (Trotec) but did and do recommend them for the strengths they have, but also warn of weaknesses.

Same with this S3XL. Friends and customers ask what I think about my equipment, and this machine is beefy. It has a lot of great features, and has some limitations. I think a few added bits could help it along just a hair, and thats the point of the thread.

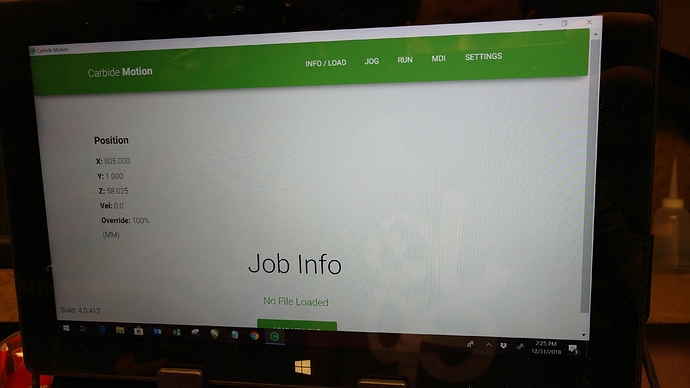

Speaking of the point of the thread, this is what the control screen looks like to me: Not finding any good way to tweak the settings or layout, and it seems to not like portrait mode at all. When a job is running, you have to grab the scroll bar to check feed rates and that it accepted any input, which is a bit less than ideal. Not sure how many others are running off a tablet, the form factor seems good for this use.