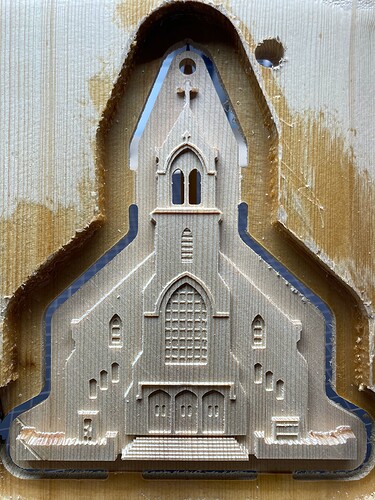

Made from what I think is white pine. This wood is from the original construction of the church in 1884. (This is a very old building by USA standards  )

)

It’s a christmas ornament for my in-laws who were married in the church 40 years ago. (The church burned and was demolished this year.)

This was a challenge to myself in a number of different ways. Because this wood is first-growth it is very fine grained, and I really pushed that to the limit here. Did not intend for that to be part of the challenge but it certainly came out that way.

I have some design tweaks which I will make, if I make more of these. The hole at the top is a bit dodgy, and ugly. The cross got ruined in the roughing passes because of a CAD mistake, or at least a poor choice on my part. Interested to read your thoughts.

Whatever finish I use here will need to have a lot of what I call “capture” – don’t know the right term? It will need to essentially glue this thing together before it breaks. I’m up for suggestions.

SO3 XL

Roughing with an 1/8-inch flat end mill Amana 46299

Finishing with 1/32 ball end Amana 46280

Carbide 3D 60-degree V for the text