For your 30 Degree V-bits … for small text in wood … do you folks generally purchase/use the .005 or .015 tip versions?

Thanks.

For your 30 Degree V-bits … for small text in wood … do you folks generally purchase/use the .005 or .015 tip versions?

Thanks.

Whenever possible you need a sharp tip. The reason is with a rounded nose on a vee bit the BitSetter assumes the round point is a sharp point so simple vcarve and advanced vcarve will come up shallow.

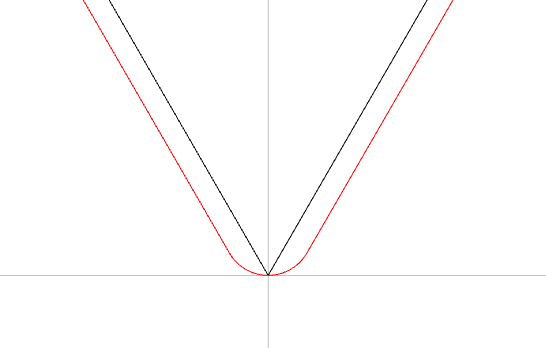

Here is a crude illustration is what goes wrong. The rounded nose vee bit thinks it is at the tip instead of further up the sides of the vee bit. That makes your vcarve shallow.

The two triangles were drawn the same size but the round nose tricks the BitSetter that the round nose is the sharp tip.

You can use a round nose vee bit but you would need to manually compensate for the difference to get your carve at the true depth you want. You would do that by manually figuring out the difference and jog down that difference and set Z zero there. However for a advanced vcarve that would make your flat end mill cut deeper. For a simple vcarve that would work but not so much for an advanced vcarve.

Guy … thanks for the response. Does this mean that you consider a .015 tip to be more like a rounded nose v-bit? .015 is still quite flat and not really round — but I do understand your comment and illustration! I am new to my Shapeoko 5 Pro and confused on the different types of v-bits available in 30 degrees. I am current looking at the SpeTools 30 degree round bits and they have 3 of them. (I already have Carbide3D’s 60 and 90 degree bits)

4 flute — Spetool 30 Deg Carbide V-Groove Tiain Coated 1/4 Dia Chamfer End Mill

.005 tip diameter — SpeTool 30 Deg 0.005" Tip 1/4" Shank V Bit Long Service Life Coated

.015 tip diameter — SpeTool 30 Deg Engraving V Bit 0.015" Tip 1/4" Shank With Long Service Life

I am just not sure which exactly which is the best one for my use case … or for that matter, what are the use cases for each bit. SpeTools does not seem to provide differentiation in the use cases. Neither does Amana for their different 30 degree bits.

An Internet search results in talking about 30 degree vs 60 degree bits, but I can’t seem to find (yet) a site that talks about the different types of 30 degree v-bits. I was hoping to tap the vast community knowledge here to differentiate the different 30 degree bit types.

Thanks again.

The problem isn’t so much the depth. The bitsetter will set the tool length to the bottom of the physical tool. So, theoretically you should get the same depth either way.

But if CC calculates a Vcarve with the pointed (black) tool, and you cut it with the rounded or flat (Red) tool, your cuts will be wider than programmed. This is one cause of sloppy fitting inlays.

You then need to compensate for the difference by offsetting all your vectors inward by the radius of the round or flat tip, and round all of your sharp corners by the same amount.

Sometimes the difference is so small it won’t matter, But ideally you want a sharp pointed V-bit

So do you guys use the 3 or 4 fluted bit or the pointier one with the .005 or .015 tip diameter?

I have the Carbide3D bits, and some of Cody’s (Cadence Mfg) downcut bits. Both with sharp points. And because the flutes are straight on both, they’re really easy to sharpen. ![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.