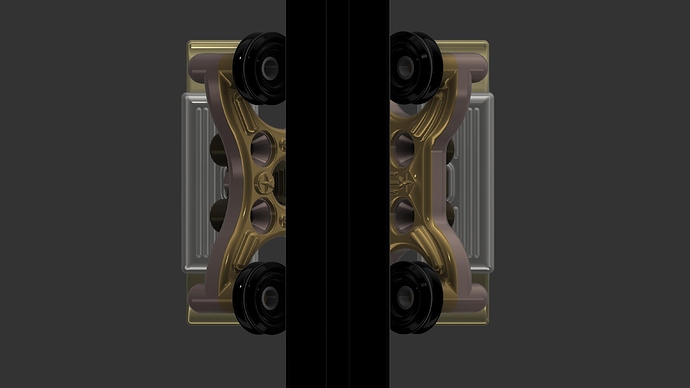

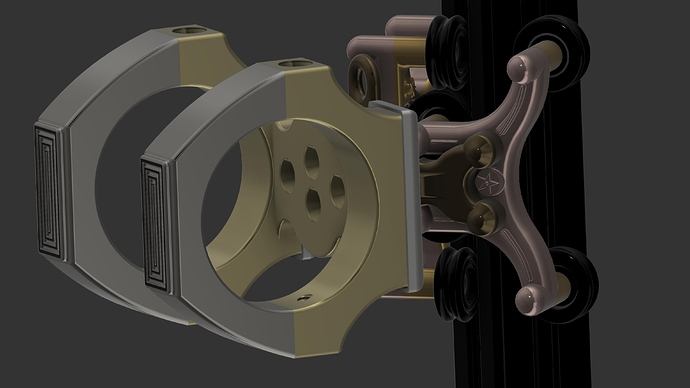

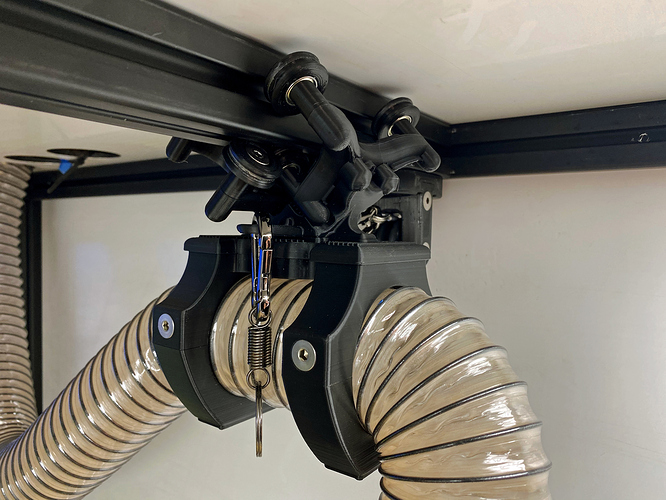

Made lots of progress but I found a way to break it,-Twist with both hands, and it fractures the V bracket bolt housing. Will redesign with stronger bosses and possibly a add on anti-twist bracket with additional horizontal locating wheels for applications with twisting forces.

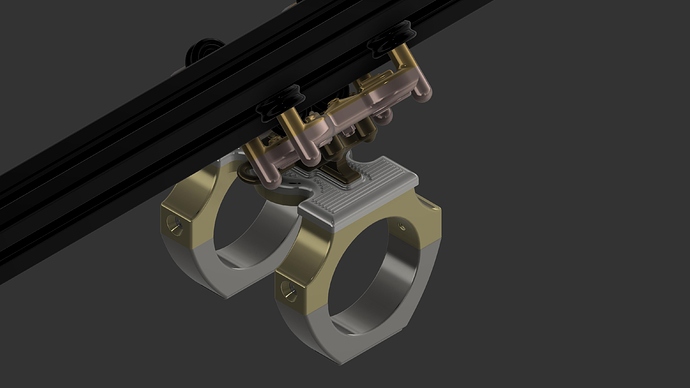

Latest design has upgraded hose cradle with 1 inch thick hose rings with fat attachment tabs for the 1/4 flat head socket cap screws. Can’t break them and I am very strong.

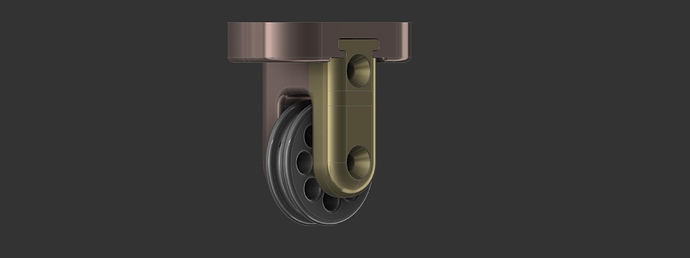

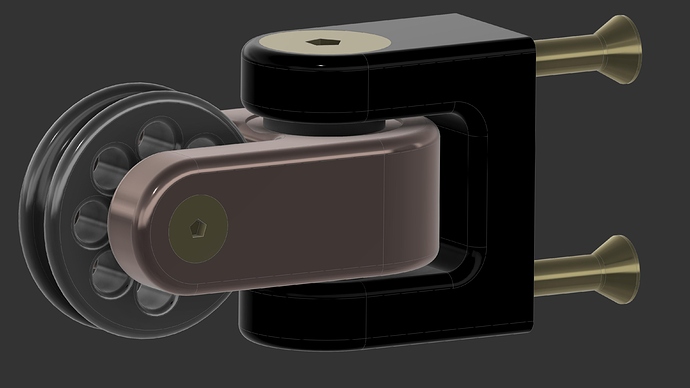

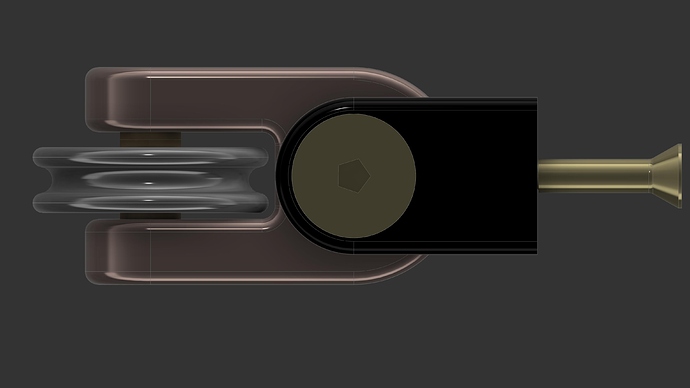

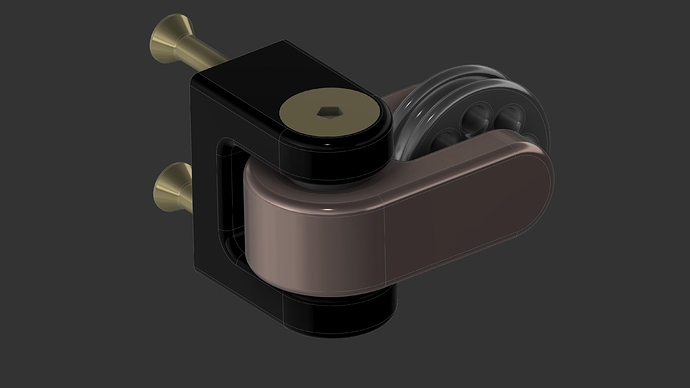

Designed a straight and swivel pulley system for the counterweights.

Currently working on a pull/pull method so the gantry is not dragging the hose, but is attached to a set of pulleys to keep it located where it should be.

Lots of editor photos, actual photos at the bottom… Rendered with Brass, Copper, Bronze, Silver, Gold and Platinum. When turned on the Vac shrinks up any slack in the hose.

![9-23-2020-5|666x500]