So, I am going to try to cut a couple of foam gaskets from 1/4" thick textured silicone foam. Being the naive simpleton I am, I figured I would just do the blue tape and superglue thing and glue down these three different durometer foam pads and be done. I mean, it worked fine for the leather that I cut before, and the neoprene foam sheets as well. . .

Well, funny thing about silicone. It is awesome in that nothing sticks to it - even when you want it to. So, after applying (or trying to apply) the blue tape, it just kind of. . .unstuck itself and curled back up.

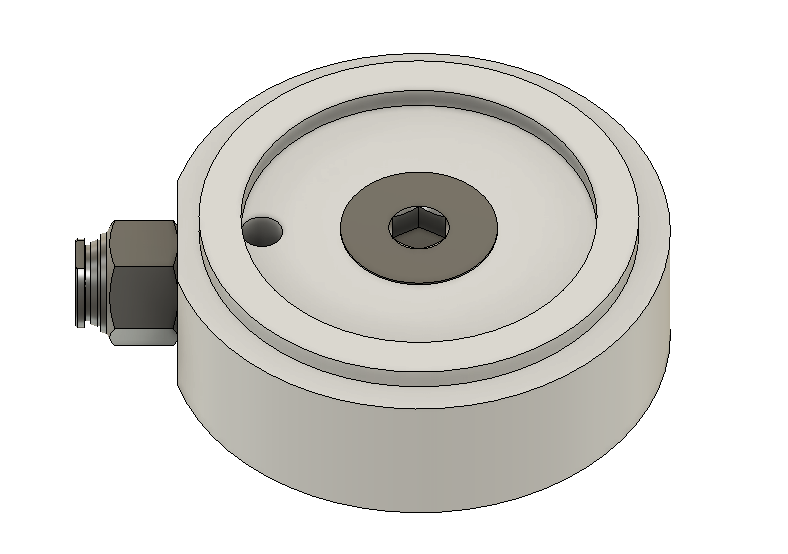

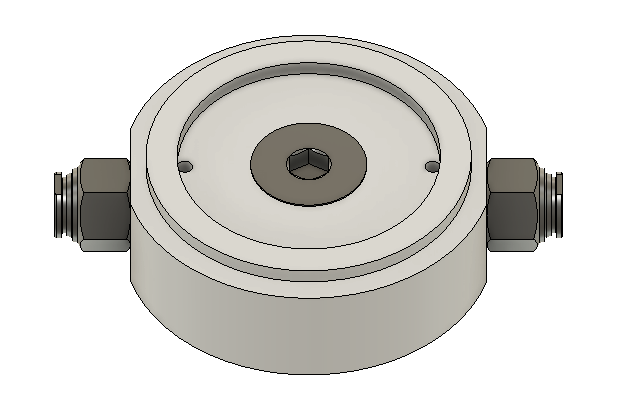

So, after contemplating purchasing adhesive tape that sticks to silicone (3M 9731 will do it) I figured I’d give it a go at designing a small custom vacuum table for this job.

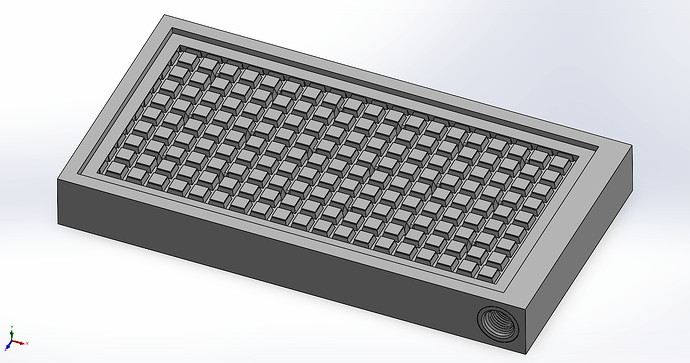

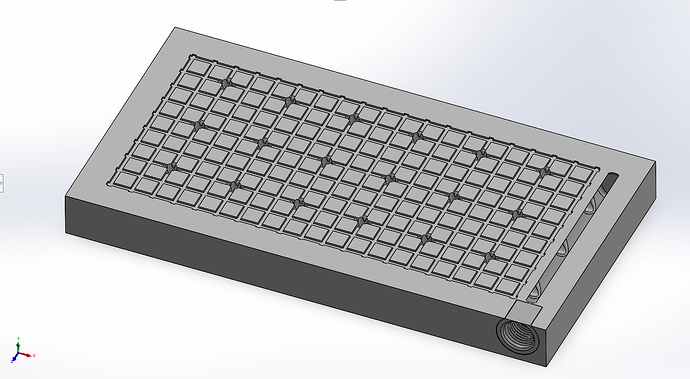

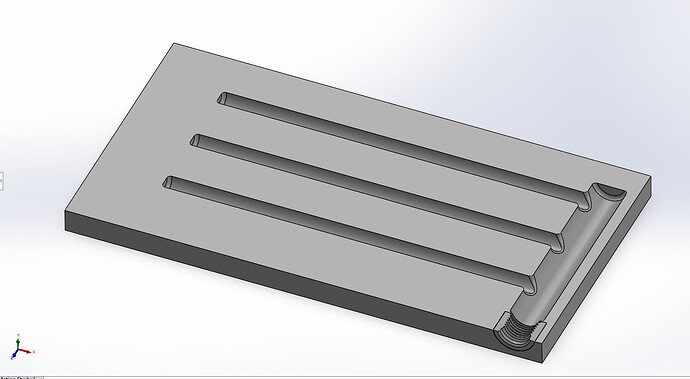

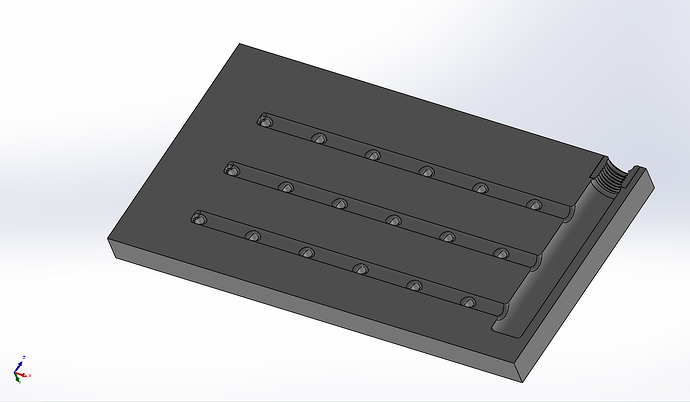

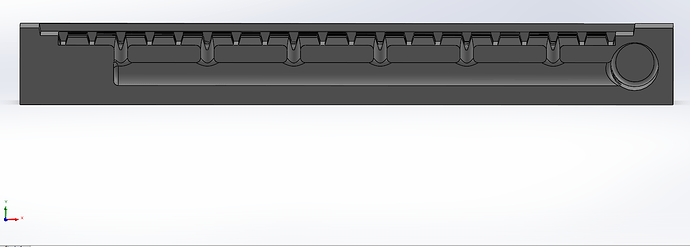

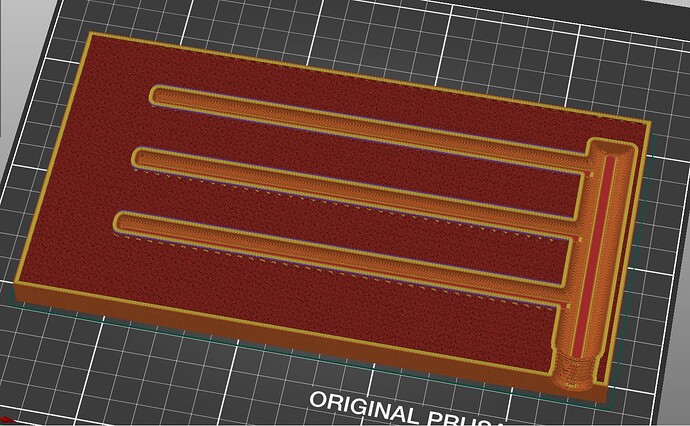

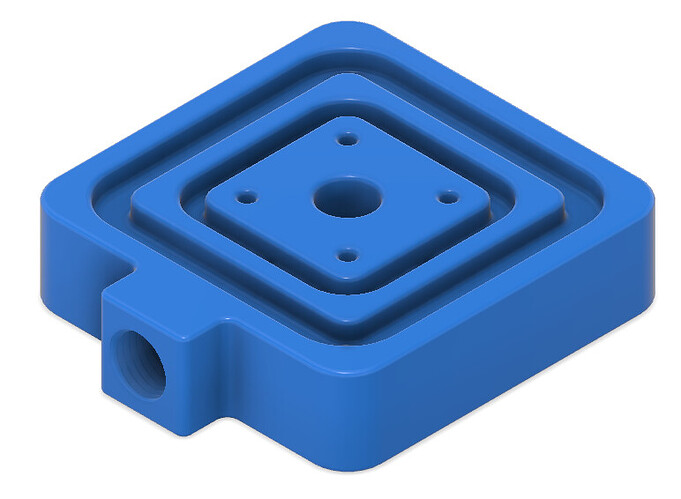

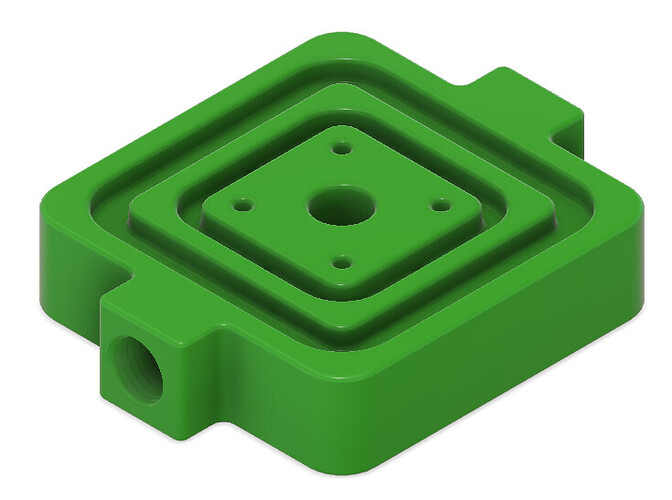

I will probably make a 1/4" plywood plate to go on top of this that I can surface to get a nice flat and parallel surface to hold the foam rubber sheets. Then, cut the through holes and channels specifically for the gasket shape I need to cut. The channels are 0.125" wide, and the islands are 0.50" square. The holes to the surface are 0.177" diameter - as wide as I could go and not cut into the islands. The vacuum channels inside are 0.30" diameter, and the large manifold at the fitting end is 0.625" diameter.

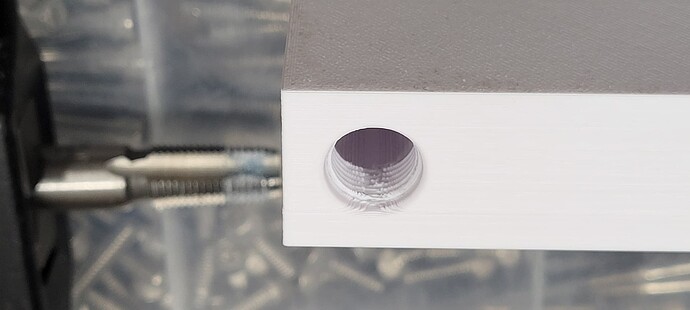

I am lazy and didn’t want to design the 1/4" NPT threads, so I just grabbed a McMaster-Carr butt weld female threaded 1/4" NPT fitting and created an assembly, then located them and exported the assembly as a single body STL, which PrusaSlicer handled just fine.

In about 26.5 hours, I’ll have something to try out.