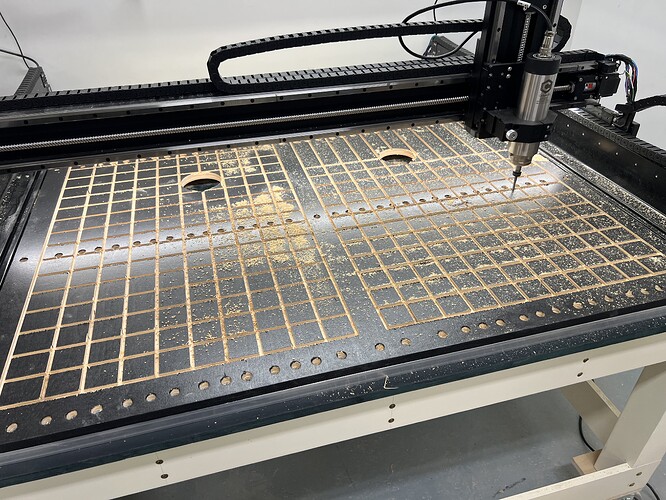

I bought the 5pro 4x4. I chose to deviate from the hybrid table. I secured my machine to my table and added a 3/4” Baltic birch plywood base. I drilled and countersunk the 96 screws to fasten the plywood to the table. Going to be pulling vacuum through an MDF spoilboard. I purchased the black box cyclone vacuum pump.

Keep us posted on the progress.

I have seen others make vacuum tables. How do you seal off the project area or is the vacuum high (low) enough to keep the whole project and spoilboard holding? I have been thinking about getting a vacuum for my lathe to hold bowls and it could do double duty as a vacuum table on my Shapeoko. The good vacuum pumps cost $$ but if I could use for more than one tool that would help justify the cost. The actual hardware to attach to the lathe is not that expensive but the vacuum pump is the big bucks. Plus I could get a vacuum chamber for epoxy.

Just reading posts on the forum costs me money.

The vacuum

Pump is strong enough. I will have it set for 2 zones that will be controlled by gate valves. If I run into issues with holding something smaller down all I’ll have to do is put a sheet of material thinner than the workpiece in the unused area of the zone.

I recall IDC Woodcraft reviewing some vacuum table. The product had what looked like rubber tubing to allow you to direct the suction only to areas you wanted to use for smaller parts. Basically you blocked the path from areas you didn’t want the suction to act on.

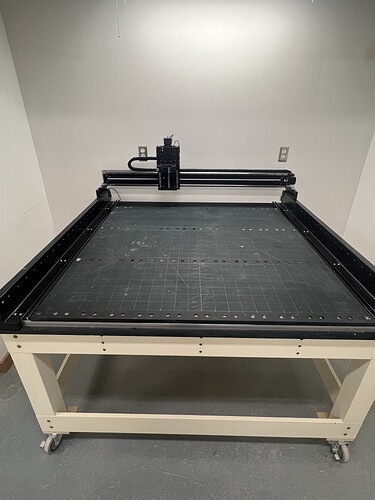

Does the lack of hybrid table affect the sturdyness on the machine itself?

I still used the 4 frame rails that go left/right on the machine. I fastened the CNC to my table in 16 places (4 per rail). The 3/4” plywood is screwed to the rails using the same screw locations as the hybrid table. I see no issue with lack of rigidity the way I did it.

As long as you’ve braced underneath the plywood top, I found mine sagged over a period of 6months. Why not use the included t track for rigidity fill it in and lose a tiny bit of z height as the hybrid table itself is fairly rigid but does flex under a point load

I would really consider that the bare minimum after running it without rails for months and seeing how a 20lb point load flexes the hybrid table. ya did good

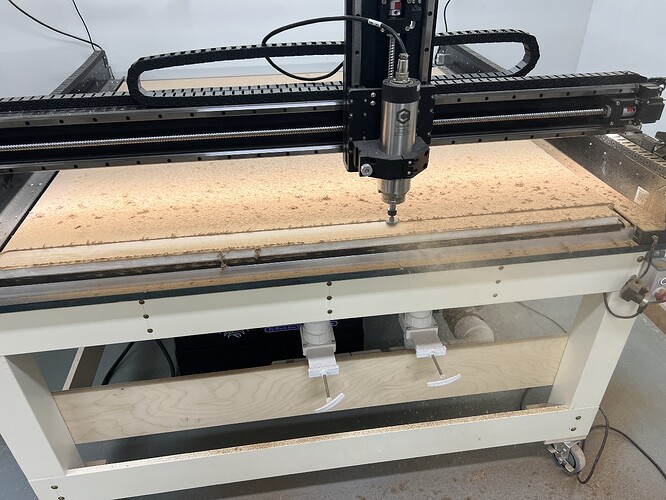

This is the table design I used. It is really stable. This one was for my pro xxl. I built a new, bigger table for the 5 pro 4x4.

Oh yeah no sag in that ever. Looks good!

Try Allstar CNC. They make this gasket tape specifically for vacuum tables. I did a huge project a while back making catch all trays and I needed a way to array and hold a bunch of small parts. This stuff worked like magic!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.