Thanks, it was also a lesson in running finishing passes, even in plywood (0.5" baltic"). Was cutting at 3000 mm/min with a 1/8" bit at 17000 RPM. Interfaces were as much as 1mm off.

What does the orange acrylic do for the laser (or you?) ![]()

The acrylic is slimming for the laser- it’s a 7.5W 405nm diva. For me, on the other hand, It keeps me from having to don the geeky laser safety glasses. Plus, other folks can be in the room without me making them wear the dorky laser safety goggles (but I make the grand kids wear them so I can take pics and post them on facebook for fun).

Perhaps there’s another word that you meant to type?

Runnin8, that is one of the best enclosure designs I have seen. So much open access with easy to use lids and it looks so cool when they are both open. Very well designed!!

-To be honest the older I get the worse I am at pool, I need reading glasses now, at age 52 and I cant focus on my shots… I used to win tournaments and run the table all night! Now it is a miracle if I make a half table or longer shot!

Dimming I assume? D next to the S…

Sorry, I can have a strange sense of humor at times. I felt I should come up with an acrylic benefit for the laser. Along the lines of, “No honey, I’m not planning to take up fishing. The Columbia shirts make me look thinner!”

I can relate to the glasses thing… I’m nearsighted and as I got more serious about playing I eventually had my optometrist make be a set of glasses with the lenses upside down so when I was down for a shot I was looking through the center of the prescription. Took him 4 times to get it right. I donated my 8’ Olhausen to Habitat for Humanity when we moved to the sailboat. Still have my custom cue and Justis case though.

I need 3 pairs of glasses and a telescope to compete… After a few beers add in a periscope…

Living on a Sailboat! Hows that working out?

Digging the tv idea brother. Mine will probably go up top.

Nice Job !!

Don’t know what kind of top you plan for that frame.

Will you have access to the frame when the top is on?

I was really glad to be able to shim my table top from the bottom while fastening it to the frame.

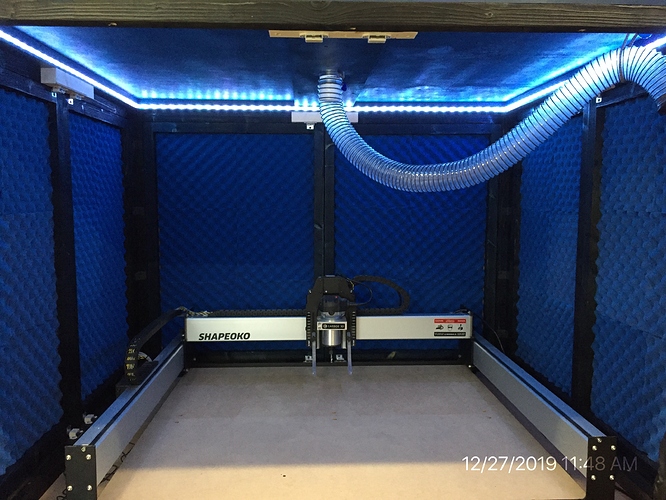

I really like your enclosure. The multiple swing doors are amazing. I was thinking about a set of right side doors on mine… I very much like your LED lighting! I have a few questions:

Does the sawdust and chips get embedded in the sound proofing? Looks like it would be hard to clean.

Also the caster wheels look kind of small for all that weight? Are they heavy duty?

So much work and very nice job!

Looks cleaner than my house! Do you actually use the machine or is it just for looks, like the towels my wife puts in the bathroom?

Actually it looks fantastic! Well done!

I used the idea of Dave Langkamp on YouTube. He has a 7 part build series on the cnc enclosure. I added/modded to my own needs, but for the most part, the middle up is mostly from his videos. He puts a window in the top, but I just put my dust collection hose through the center of my top. I also shou sugi banned the frame, although it is hard to tell from those pics. I have the xxl, and I highly recommend multiple access from all sides when doing an enclosure.

It is new, but I have probably 50 or so hours on it. I try to keep it looking good. The rest of my shop doesn’t have that good of dust collection.

I haven’t and don’t run my cnc without the dust boot and good dust collection. If the foam gets dusty, I have air run in my shop to blow it off if needed. My castors are 3”, and hold 350 lbs each for a total of 1400 lbs. I may have 300 or so lbs in it. Harbor freight is my friend.

Mindless corpse, if you are referring to the torsion box, I do not have access to it. A proper torsion box is sandwiched with a top and bottom. I have 5/8” ply for the bottom and 1/2” mdf for the top of the torsion box. My xxl sits on top of this. My xxl also has the spoil board that comes with it, and 2 more 3/4” mdf spoilboards on top of that. Sometimes the extra spoil board makes carving thicker pieces tight, but so far so good.

Thanks.

After reading I looked up the principals of it. I guess I have built a few of them without even knowing it had a name…

It’s basically a built hollow structure that transfers load energy -vs- stretch of the bottom material?