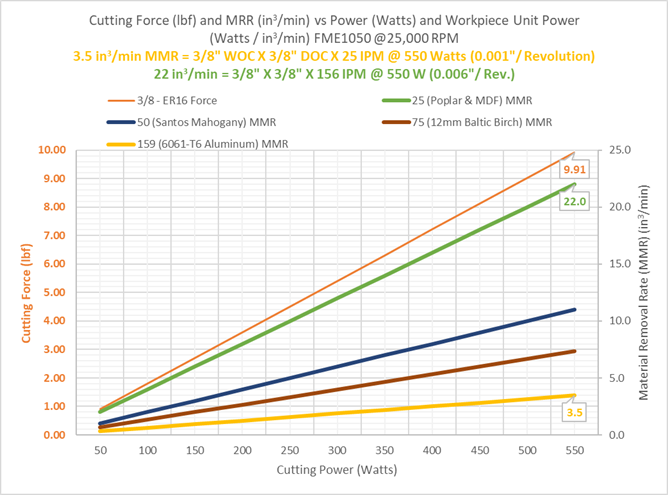

IMO the ~$300 AMB 1050 FME-P would be a huge step-up from the Dewalt and Makita routers. It has a precision ER16 collet and balanced nut, more power, and is lighter weight. As shown below, a one flute endmill might be required to get an adequate chip-load for 6061-T6 aluminum (0.001" according to @Vince.Fab). If he could still afford lunch after investing in that upgrade, he’d have more time to eat it.

1 Like