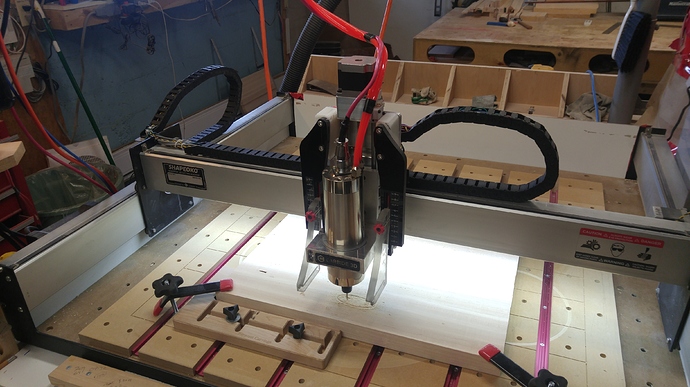

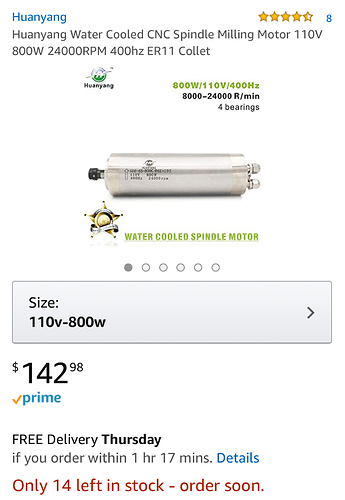

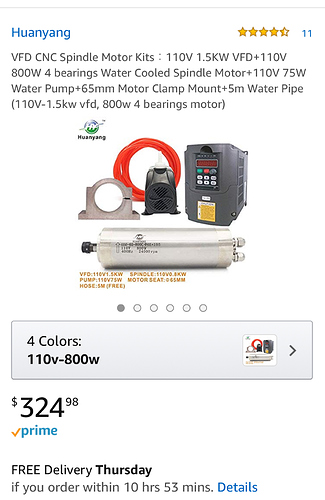

I recently upgraded to the 800 Watt, water cooled, VFD Controlled spindle kit that’s readily available on Amazon or Ebay. It’s the Chinese Huanyang 1.5 Kw VFD with 800 W 110 Vac version. I chose to go with the 800 W which is within 10% of the HP of the Dewalt router that I had been running on the Shapeoko for the 2 years. The biggest reason I didn’t go larger was I didn’t want the hassle of upgrading my X axis carriage to handle the additional size & weight of a much bigger motor. I recently upgraded the Z axis to a slider, and firmed up the axis sufficiently to improve the quality of my work, but this also made me aware of how hard you can push the X & Y axis before the next level of issues start to show. Also I’m using my Shapeoko to create 3D carvings in hardwood. Most of the time I’m using 0.5mm round nose bits so more HP isn’t needed by me.

Overall it took me an afternoon to upgrade the system, most of the time was spent playing with the VFD & Motor on my bench before installing on the Shapeoko.

Here are the steps & my thoughts about each:

-

Previous Completed Upgrades - I previously added the wiring to the controller card and bought an external solid state relay to turn my router & dust control system on & off automatically. (plenty of info in the forum & Wiki pages already on this subject) Overall this made integrating the VFD control very easy vs starting and stopping the motor from the faceplate of the VFD.

Z Axis Slider installation - previously completed, but not required for this upgrade. The OEM Z axis will work fine with the spindle motor, weight is very similar and spindle will fit into OEM mouting system with the Makita shim that comes with the Shapeoko.

-

Additional equipment required:

-

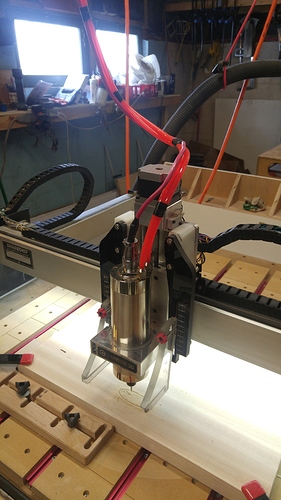

You need to purchase a cable to run from the VFD to the Spindle motor. I used a 4 wire overall shielded 18 awg contol cable rated for 300V. The terminals can handle a 16 awg, but I went smaller so the cable would be more flexable. 18 Awg will handle 10 amps, when the system is running under the heaviest load with a 1/4" endmill it draws 1.0 amps

-

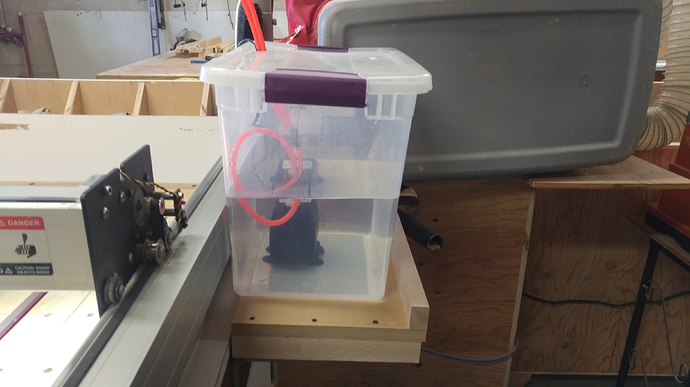

you need to buy some sort of bucket or tub to hold the water for the cooling system. There is much discussion that you can purchase better pump or proper chiller unit with proper cooling fluid. I’m running with the pump from the kit and using distilled water. I also a solids meter that measures the ppm of material in your water (had for my RO systems) they sell for $20. My though was start out simple and upgrade this stuff later if needed.

-

I needed 1 110VAC relay to start & stop the VFD automatically. I just wired the 110 coil of the relay to a standard 110 plug and connected it to my existing solid state relay that I was using to run my dust control & original Dewalt Router. I looped the 10 VDC from the control terminals on the VFD through the contact on the relay. There are plenty available on Ebay or Amazon for $3 to $5.

-

Need the Makita insert from Carbide 3D. Mine came with the unit. This allows you to use a 65mm diameter spindle in the standard mount on the Z axis.

- Instructions & Manual:

- Basically it’s “Chinglish” so You Tube is your best friend. Plenty of videos out there, not on the 800 Watt, but the larger ones wire up the same. The manual is accurate, and my unit came pre programmed so didn’t have to do much. I will also state my viewpoint is I’m a retired controls guy who worked in a Japanese Auto Factory for 30 years so bad documentation is normal to me.

- Grounding:

- In the manual and the online comments they don’t use grounding of the spindle motor. This is normal in the Asian Control Market. However, the Spindle is a 4 pin connection. 3 pins are for the control voltage. the 4th pin is connected to the ground of the spindle chassis. I followed North American standards and connected my 4th wire to this and connected the other end along with the cable shield to ground terminals in the VFD.

- Parameter Set Up.

Here are my final settings for the Parameters on the VFD.

001 - Source of Run 1 (terminal strip)

002 - Source of Frequency 1 (Knob on VFD)

004 - Base Frequency 400 (Hz)

005 - Max Frequency 400 (Hz)

008 - Input Voltage 120 (Cnd Std)

014 - Accel Time 0.5 (sec)

015 - Decl Time 0.5 (sec)

070 - Analog I/P 1 (0~5 vdc)

072 - High Analog Freq 400 (Hz)

144 - Frequence Display 3000 (used to calibrate rpms)

Overall Impressions of the upgrade.

Top Benefit: Quiet, Quiet, Quiet - wish I had done sooner. Cant say enough.

Speed Adjustment: You can properly tune from 100 to 24000 rpm’s you will improve your chip loading and also can adjust for the best cutting quality.

Excellent torque and speed consistency. - I’ve checked with my non contact tach meter. Rpm’s are deadly accurate to what the display says on the vfd.

Overall if your tired of the noise, and replacing the burned out brushes on your router, but don’t want to be bothered with a major upgrade for the 2.2 Kw spindles this unit is great. As for longevity I’ll update if any issues arise. Currently have 300 Hours on it with no issues.

Here are some picture of the upgrade, (I’ve included a picture of the bag of brushes I went through in the last year needless to say happy not to be ordering them anymore)