As a CNC hobbyist, I’ve experimented with many of the most widely used CAD programs, and found most of them to be targeted well beyond my needs (apart from their intolerably long learning curves). Do I really need Vectric’s digits of accuracy or Blender’s features for creating animations or Fusion’s multi-body components, when all I’m trying to do is cut holes in a hunk of walnut? ![]()

So I applaud C3D for getting it right with Carbide Create. CC has all the tools needed for basic 2D design; things like basic regular closed figures, line drawing, text, repositioning, enlarging, rotating, reflecting, grouping, and aligning). More importantly these tools are presented in an intuitive way. (My grandson, who is ten, could learn to drive this user interface in minutes.) The 2D toolpaths of CC are similarly well suited for the hobbyist. Further, CC has the tools I need for somewhat more advanced 2D geometry. (I’m thinking of things like booleans, editing points, cornering, joining, advanced VCarving). Perhaps the most significant issue is that the CC user interface isn’t too cluttered.

to get to my point…

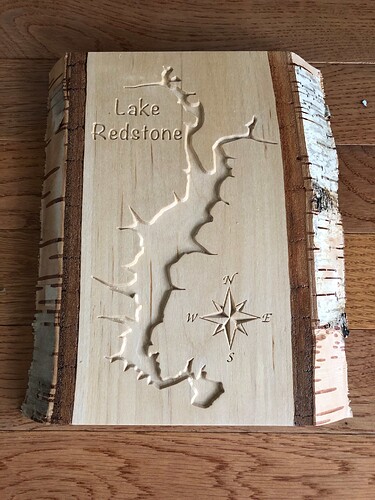

The Modeling tab is what really takes CCP to the next level. CNCs, at least for us hobbyists, carve into fixed material with a revolving cutter that always points straight down. Of course, that means that many 3D volumes simply cannot be produced as a single CNC object - a fact that 3D CAD packages largely ignore. (I do understand that CNC is only part of the user base for commercial CAD software, but my point is that all the unnecessary features and capabilities actually get in the way of CNC work, especially for a hobbyist.)

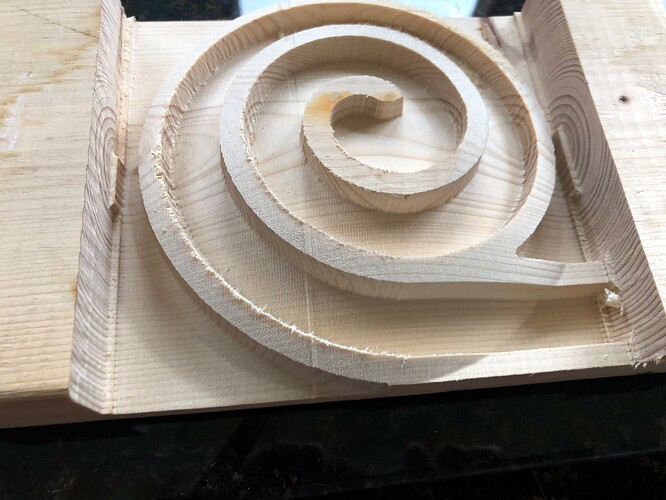

CCP modeling is truly unique in that it views the 3D world from the perspective of the CNC. That is, the modeling tab only supports adding/subtracting in layers along the Z axis. No, it can’t create many kinds of volumes, but the concept should work for constructing anything we can carve on a basic CNC setup. This modeling technique is truly unnusual, avoiding the awkwardness of extrusions in unnecessary directions, constraints, and mesh manipulations; along with the maddening difficulties of trying to position 3D parts on a 2D computer display.

So I’m hoping this message will encourage you C3D folk to continue with CCP. I’ve already suggested a couple of small improvements and will post others under the new feature request subject; I encourage other CCP users to do the same.

I believe that the pricing of CCP, at about an order of magnitude less than most CAD/CAM packages, is in the realm of hobbyists. I might also point out that CCP could be very useful to the 3D printer world given replacement of the toolpath component with slicer software.