Continuing the discussion from I've run into enclosure design issues with the vaccum hose:

My primary goal for this enclosure was noise reduction.

The table is utilitarian. It was built with 2x4 fir, ripped down to 3” wide, and lap joints. 1” prefinished maple as the table top. Still building out the rest; control panel (it has to switch sides) drawers, dust collection, etc.

The overall size of the main box is 66”wide x 48” deep. Later, I added 6” to the back. I needed about 2” extra depth to be comfortable but since it was already something i was going to do, I kicked it out to 6”. It’ll end up being 66” x 54” not including whatever kick-out for the control console.

The enclosure is 3 layers of 3/4 birch plywood, and it was designed specifically so I could cut all of it on the Shapeoko. (An excellent primer for cnc use btw)

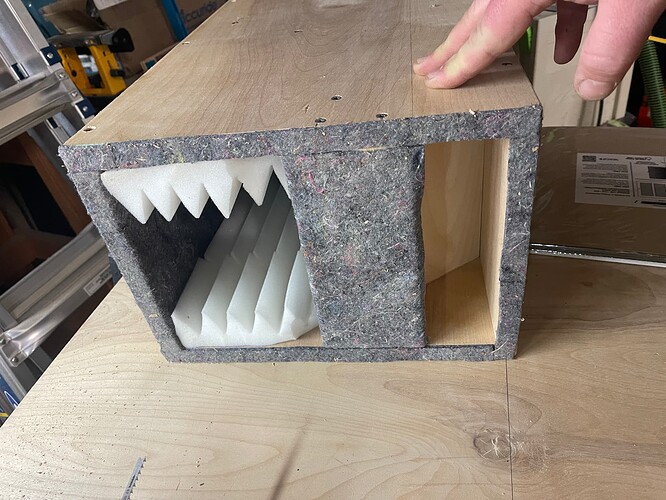

Sandwiched between the inner two layers of plywood is a layer of 1/8 felt. It was previously laminate flooring underlayment and it deadens the sound really well.

The windows are double-pane 1/4” clear plexi, that i sandwiched between layers of weatherstripping to give it an air pocket.

I had originally planned on lining the inside with white 2” acoustic foam - the wedge shaped stuff used in music studios. But after doing some cutting with the machine this weekend, It doesn’t seem like I’ll need to, and I’d rather see the birch grain anyway. I may still put foam on the ceiling or the back panel. We’ll see.

Dust control system is all rockler fittings going into a separator and an old rigid shop vac. Suction is very powerful and there is zero dust. The exhaust from the vacuum goes through a felt and foam lined box as a sound muffler, and the entire dust control compartment will be vented using ac infinity fans to keep the vac cool. The vent fans themselves will also go through sound deadening mufflers. The inside of the whole compartment will be lined with gray outdoor carpeting that I got from Home Depot.

The machine sits on a layer of 1/4”hardboard that is sitting on a layer of the underlayment felt that is sitting on the 1” maple tabletop.

The top of the box is currently just a single layer of ply that has the lights cut into it, but it’s recessed about 4”, so I’m going to fill the void with some rock wool insulation and cap it off with a final 3/4” piece of ply on the very top.

I’ll probably share more photos down the line so I’ll break this off as a new thread.

Let me know if there’s anything you’d like to see better. I can probably upload the sketch ups, although they’re not accurate to the final as I made changes on the fly.

Thanks for checking it out. Constructive feedback is always welcome.