When in Carbide Motion and ready to start a job and the screen tell you to turn on the router to cut and you realize that you need to make a change the only way to stop the process is power off the CNC and start it back up again and go through the process again. The software screen does not allow you to choose to stop or pause the job. There should be an abort button to stop the process rather than turning off the machine. If you choose to click on the X in the top right-hand corner or any other button on that screen the process will start your job. It would be nice not to reboot the machine and load a new file because you forgot to add something at the time of the cut.

Not every stop needs to be an emergency. There should be a way to stop a job that DOESN’T need to re-initialize the machine. It should just stop the spindle, and retract on Z.

Some thoughts on

There is a Start/Pause/stop button that comes up as your file runs. The pause button pauses the execution of your project file and will pauses the code from executing in carbide motion and stops XY and Z motion. Z does retract.

Maybe it’s lunchtime or you need to secure your material better (cut off router).

Start button will get carbide motion to continue executing the project file you loaded from where you paused it. (turn on router)

Pressing stop ends the code from executing in Carbide motion and sends the router back to the home position.

Pressing start again will execute the same project file, from the beginning), already loaded but uses the same XY and Z zero point. This is for cutting a second part using the same file already loaded.

Some time it ask if you want to use the same Zero point?

When you turn on Carbide motion you have to download a file made on your computer and set the zero point or use the old one. Carbide motion can’t edit that file in anyway.

Any changes to the file being executed by Carbide motion need to be done on your computer and reloaded to carbide motion.

Not sure this answered your question, I just had some extra texting ink that needed to be used.

The carbide create guys will jump in and say if this is correct.

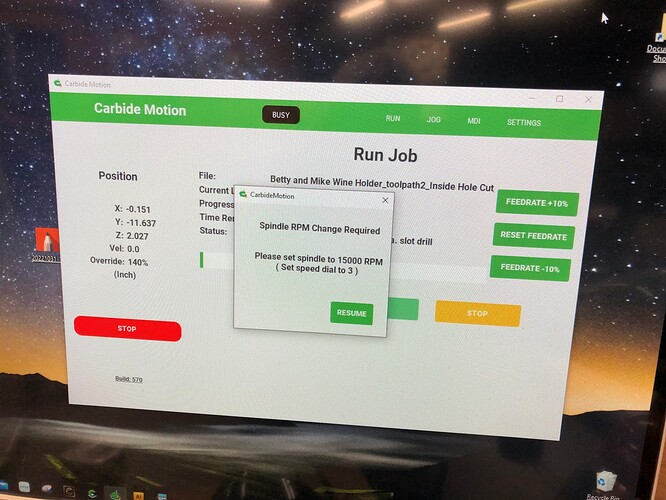

This happens when the file is loaded, I have changed the bit and the router returns from the bit setter. The screen now says to turn your router on a 10,000 rpm and you press the start button. Now, at that point I realized that I need to change the file loaded. The machine will start if you press start or the red x in the top right-hand corner. The only way to get out of the program is to disconnect the machine my turning it off so the Motion software disconnects from the machine. Now I have to turn the machine back on and reload the file to cut that I changed. That is the only way to stop the process from starting.

I mentioned this last week as well

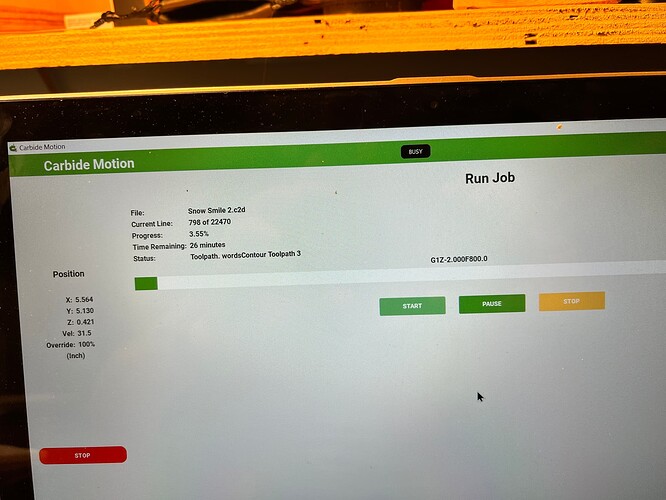

Just to make sure we are on the same page. I am running Carbide Motion 566 and see this page when the job is cutting. Pressing PAUSE will pause the job from cutting, next press START or STOP. START will make it start cutting again. STOP will terminate the cut/job and send router to homing position. START and STOP on this line do not work until you press PAUSE.

I do have may BIT Setter off, but it should work the same but with less jiggling.

Thank you for getting back to me.and I am using Motion 570. I have attached a pic of the screen that will not let you abort the job. The only way is to turn off the machine and restart. It would be nice to have a button to cancel the job without having to reset all over again. I am bringing this up because some of us who start a cut then before hitting the resume button found something needs changed or forgot to set something. It does not happen all the time but there are sometimes it does.

Maybe this is a Bug With new 570 load. load 566 is working. I would load 570 to test but do not want the bug.

I am working something in 743 CC load. They are a bit tired of hearing from me.

Time for CC Guys to jump in. I will keep following to see how this is resolved.

WillAdamsWilliam Adams (Carbide 3D) is a moderator

William Adams (Carbide 3D) calling all wills

Regular

No, it’s my understanding that this is an aspect of interface design/programming.

When the modal dialog for setting the spindle speed is presented, the only valid option the application is programmed to accept is “RESUME” — canceling out of the dialog doesn’t seem to be an option which the graphical tool kit differentiates in a meaningful fashion, and closing it using the “X” button afforded by the UI is handled the same as if one clicked “RESUME”.

By the time one has gotten to this point, there have been a lot of prompts, and one has had a couple of chances to review things — at some point, there has to be a “point of no return”, and this is it.

It’s a power tool. If something goes wrong it can badly injure you, or even amputate body parts, or even kill you if you are working alone and no one is able to come to assist you in time.

If something isn’t right, then the best thing to do is to shut the program down completely, and then restart everything so that the program and the machine are each in a known state and those states match.

Please see:

and heed and follow it.

Thank you for the information. I was not thinking about the safety aspect of the software and the machine, but it makes sense that since both talk to each other the software or machine could start without warning and cause injury. I wanted to make sure that I was not missing something and the procedure that I was using to reset the machine was the proper solution to starting the job over.

Again, thank you and hope that the community reads this and stays safe while operating their machine.

Breaking news woodworking is now one of the most dangerous hobbies.

Radial arm saw. “Robot” danger danger Will Adams(Robinson).

So am I good to load CM570? I will save old version.

I’ve been using 570 since it came out, and have already been able to send in one crash report — hopefully these will help the program get better and safer.

@zayzoo, don’t disagree that an abort or cancel button is needed on that “Set Spindle RPM” dialog. It absolutely is needed. And something also needs to be done about the machine proceding to the cut if you try to close the dialog box via the “X” in the upper right corner. That sent me into a mad panic the first time I tried it.

That being said, I have found myself in the positions you described, several times, remembering at the last minute that I needed to adjust hold downs, load updated G-Code, re-zero, etc. I just wanted to point out that the “Pause” button (on the “Run Job” screen) functions as soon as you select “Resume” and the “Set Spindle RPM” dialog disappears. I’ve found that there is usually just enough time to quickly hit the “Pause” button while the spindle transiting/plunging and that it will immediately stop and raise to a safe height.

In fact, my routine has evolved to where immediately after I hit the “Resume” button I move my cursor to hover over the “Pause” button while I closely watch the spindle move into position, start to plunge, and begin the cut. If I see that anything is off, like X/Y is out of position or Z starts plunging too deep, I’m in position and ready to hit the “Pause” button and turn the spindle off to investigate. If everything checks out, I simply turn the spindle back on and hit “Start” and it resumes the operation. If not; I hit “Stop” to send the spindle to the back corner, take whatever steps necessary, and start the process over. This has worked out well and saved my projects many times.

Hope this helps you too.

Brian

Thank you for your imput. I too use the pause button as you do to stop the machine. It is almost like an abort button but you have to chase buttons while watching the router and the screen. So both of those options work and I thought I would throw it out there and see if other users have experienced the same issue. Maybe something will change later down the road but my last post about being safe is a priorty when running the machine.

So for now these are the two options that we have for having to make a change within the software or as you said re-zero, etc.

Stay safe

Lance

I believe a Sofware update could be done here. What is needed is a single interrupt to stop all processing until the interrupt state has changed, via the GUI or a physical swt cmd.

I’m not a programmer but this is what comes to mind for a future solution on this topic. And as always keeping ‘Safety’ in mind.

That is my 2 cents.

This topic was automatically closed after 30 days. New replies are no longer allowed.