Hi, I have created a two part mold tool and want to cut this from aluminum. Stock material is 1.5” x 3” x 6”. I only want to machine out the mold portion not the sides for each half. It’s so important that the block is machined in the same place for both half’s so when the blocks are placed together they creat a mold profile that is seamless.

I plan to machine the top half of the mold then switch out the stock material for the bottom part and then machine that.

I need a very accurate datum for both half’s so that the cut is in exactly the same place for each half. How do I tell the machine exactly where to start in reference to the stock for each half?

Hope I explained that ok?!? But basically I want to mate the two half’s of the mould so that the outer edges are aligned and so is the machine mold section inside the tool.

Thanks

Hi @Wayne311,

You are saying two things:

and

If you really don’t want to machine the stock sides, then you would need the two pieces of stock to be exactly the same size (I’m stating the obvious, but two pieces of raw stock rarely have identical dimensions, unless you buy them specifically to be within a known tolerance of target dimensions)

If they ARE identical, then it “only” becomes a matter of having a precise way to reference the stock on the wasteboard for each run. You could e.g. use a corner square, that would allow the two stock pieces to be referenced to the exact same location. And then zero off the corner of the stock before the first run.

If they are not identical to begin with, your best bet will be to machine the sides too to bring each piece down to the same final outer dimensions.

Other than that,

- don’t re-home the machine between runs, there is always a risk of introducing a tiny offset when doing that.

- do a thorough mechanical check of the machine to remove any slop

- use conservative feeds and speeds to mitigate the risk of lost steps during the first run.

For it to be perfectly seamless, it will probably take a few (…) trials, so I would suggest to do test runs in a soft material, to make sure it works fine in that “easy” case, before proceeding to cutting aluminium. I would probably try to run the jobs in Renshape, there are some 3"x5"x1" pieces on the store for example.

Thanks. I get that I need to zero the machine to a specific point, but how do I make sure the length of stock is perfectly parallel to the x and y planes so that the walk thickness of the machined our area are equal all the way around. Simplistically I am machining our a rectangle block from a rectangle stock.

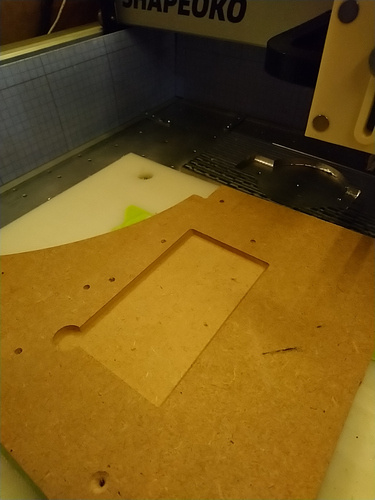

Assuming your two pieces of rectangular stock are identical, that’s where the corner square comes in: you should use the machine itself to drill the holes to attach the corner square, which should bring you close to aligned on X and Y. And then you should probably re-machine the inside of the corner, which should ensure that its inner sides are perfectly aligned to the machine’s X/Y axes. Actually at this point, you might just as well mill a pocket (with extra room/dogbone for the corner) in your wasteboard, that will act as a jig to align and hold your stock, and it will be guaranteed to be aligned along X/Y. This is what I did for this project:

Thanks, that makes sense.

If it is a 2 part mold, then build in alignment pins onto the mold.

Half of the pin sticks out of one part, and the other has recesses to accept it.

This topic was automatically closed after 30 days. New replies are no longer allowed.