Hi @tsetsefly,

Q3: I tend to remove the plastic coasting before coating when possible, it’s super soft and tends to shear/melt rather be cut by the tool, and gets in the way of good chip evac.

I did remove it for that recent project where I cut tons of shiny black acrylic, and found out that after the cut if you use a soft brush to remove the dust/chips, and then a microfiber cloth, then you can clean-up the acrylic without leaving ANY scratches.

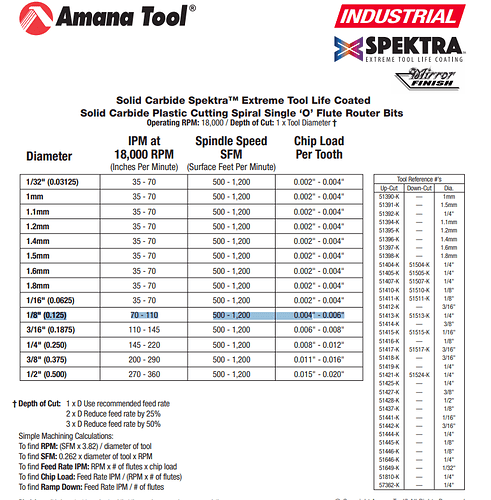

General/Q1: you are feeding 45ipm @18k on that single flute, which is ok but you could feed faster (and plastics tend to crave high feed rates). The Amana recommended values for that endmill are 70 to 110ipm at 18000RPM,

They tend to be a little aggressive, but there is probably a lot of margin for your to explore between 45 and 70ipm.

Also, in plastics I usually use a plunge rate that is at least half of the feedrate. If you plunge too slow, you may end up with melting just during the plunge, and sometimes that’s enough to compromise the rest of the cut. You should be able to plunge at 30-40ipm without any issue

Regarding A: it may be one of the corner cases where rounding errors and/or the cutter not being exactly the specified diameter, leave a small ridge like that. I’m surprised that changing the stepover did not help at all though. Usually just adjusting the stepover ever so slightly, makes the math behave.

Regarding B: yeah, probably the joint effect of a not-quite-fast-enough feedrate and the presence of the plastic coating preventing chips to get away from the cut

Regarding C: weird, but it may just be the same as A but with a thin enough ridge that it broke and flew away, leaving you with that ? (you can see how in some places of the O and the R, that extra line is not there, it’s discontinuous)