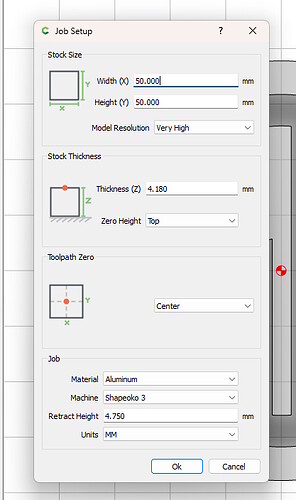

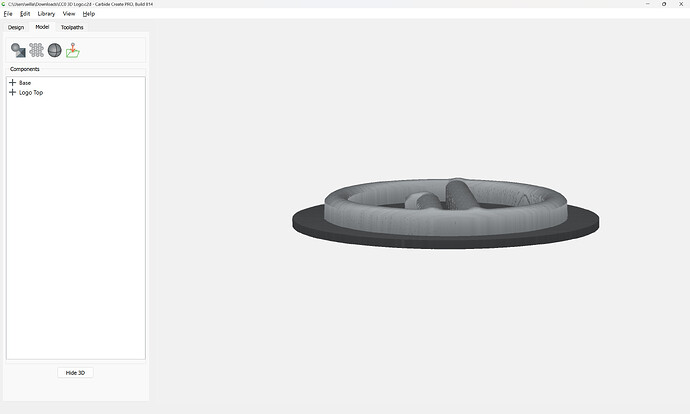

I’ve been working on this roughly 8 hrs now watching vids making changes to no avail. Can anyone see what I’m missing? I will include the proj file and pics of whats happening.

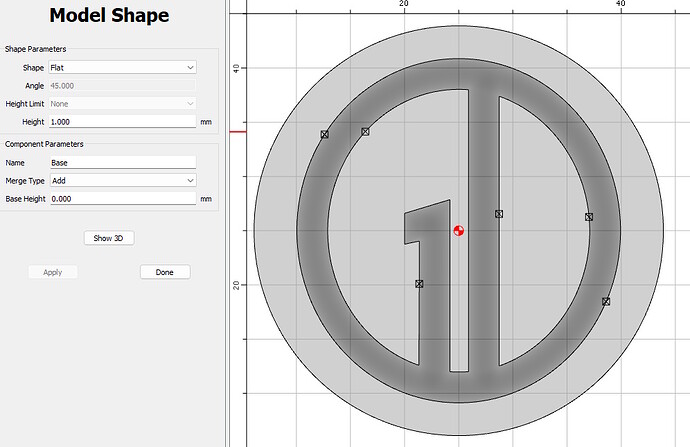

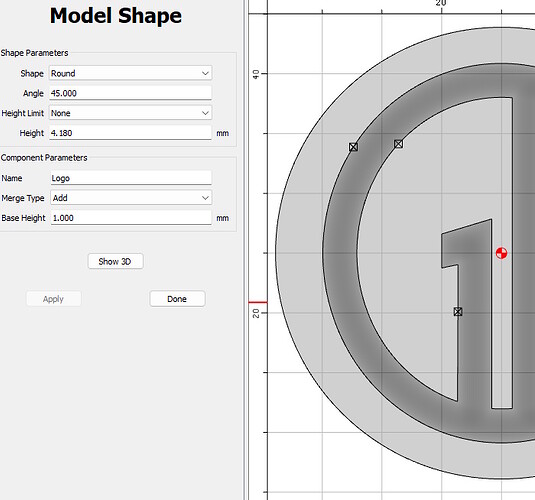

What I want is being displayed perfectly in model mode and toolpath sim, but when it cuts it knocks the top off of the rounded feature I want even though its below the stock height defined in setup. (1/8" roughing ball mill - 2mm Finish ball mill bits, CC Pro:V813)

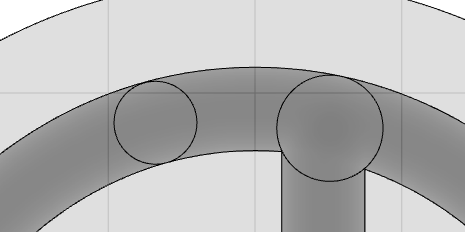

Not sure if its related, but the center bars are the same width as the outer ring but at the intersection of the ring they rise up a little. If you load the file to model lay it flat and you can see they are not even. I realize its just a graphic representation, but its math, the arc should be the same for the same size object,

CC0 3D Logo.c2d (900 KB)

Yeh, the problem with corners is there is a greater area at the intersection, so it builds the rounded solid a bit higher. If you don’t want to sand those bumps off, then model the circle, line, and the 2 parts of the 1 separately, and use a “max” merge type.

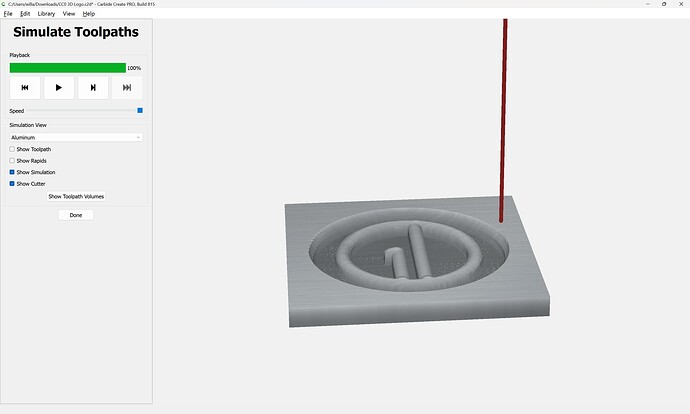

The 3D model seems quite workable to cut:

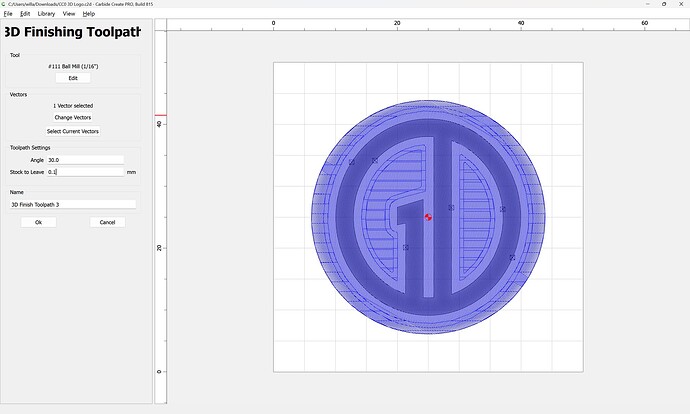

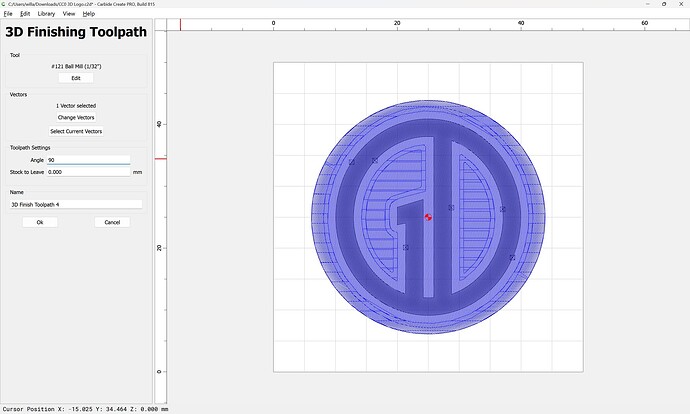

If we then use the new “Stock to Leave” feature in 3D from v815:

then we can add a second 3D Finishing toolpath:

then one gets a part which quite closely matches the 3D model:

CC0 3D Logo_v8.c2d (1.1 MB)

Thanks Tod1D. Since I made that Post, I decided to recreate it in V7 with the same parameters as a test and it cut perfectly. I am running proV813 must have some issues, sure wish I would have thought of V7 before I spent 8hrs banging my head into the wall! I guess I’ll update and play with it later. V7 was very simple to redo the project. If I had something more complicated to do, the learning time would be worth it. If I am at the computer I am not getting shop work done…lol Thanks again for your response, I’m sure I will be on here frequently! ![]()

Thanks WillAdams…Ha, I replyed to Tod1D instead of your post…ooops… Since I made that Post, I decided to recreate it in V7 with the same parameters as a test and it cut perfectly. I am running proV813 must have some issues, sure wish I would have thought of V7 before I spent 8hrs banging my head into the wall! I guess I’ll update and play with it later. V7 was very simple to redo the project. If I had something more complicated to do, the learning time would be worth it. If I am at the computer I am not getting shop work done…lol Thanks again for your response, I’m sure I will be on here frequently!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.