I had a brief exchange about this with WillAdams through the support email, but figured that I’d like to discuss it further to learn more about my several misconceptions.

I’ve been exploring adaptive toolpaths in Fusion, having so far used Carbide Create 99% of the time. The default settings with the 3D adaptive toolpath seemed all too aggressive, especially the stepdown, so I also had a go with HSMAdvisor to evaluate doc, optimal load and feeds. C110 is arguably not a very good material to go to work with, being gummy and tough, but at this point I just want to try to figure out where I’m going wrong.

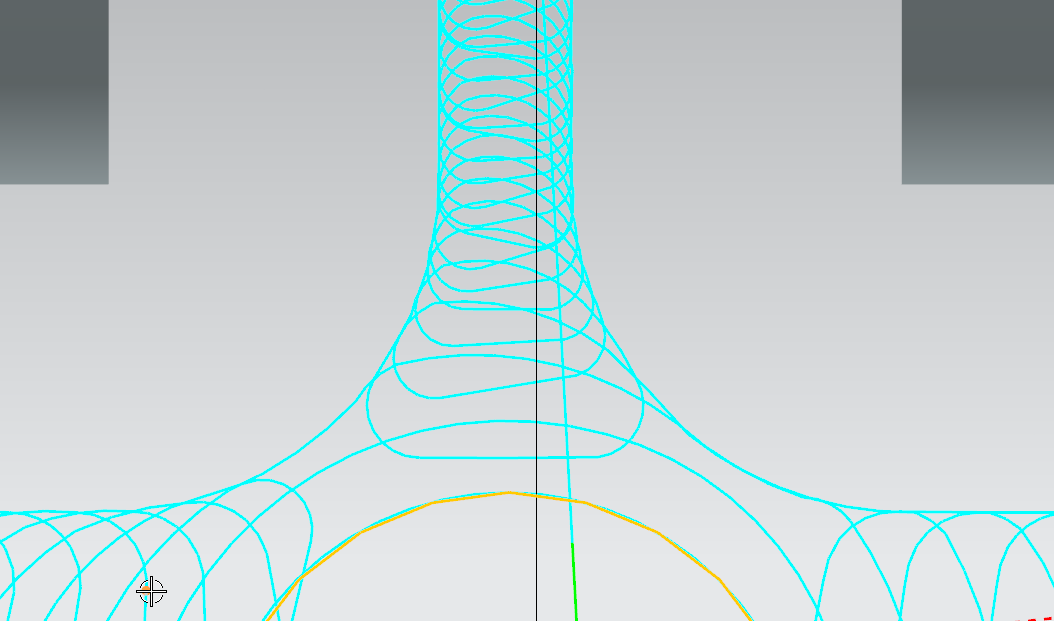

What I’m milling is a 30mm coin. The adaptive clearing seems rather straight forward, but I take it that’s where my first misunderstanding is. I tried with a #274Z, single flute cutter at 24k rpm, 41 in/min feed rate, around 10 in/min plunge, 0.0125 in optimal load, 0.035 in maximum stepdown, helix ramping 2 degrees. I’ve got a rather strong shopvac pulling air past the workpiece and end mill, so I figured that would help cool it.

About 1 minute into the operation, the mill broke clean off, during a rather mundane clearing after the second ramp. I figured I’d gone too fast, so I dialed it back to 20k rpm, 34in/min, same stepdown and optimal load, on the same coin. I believe this operation held on for a little bit longer, obviously having milled in thin air for most of the time, but that one snapped as well. No screaming, no particular warning, just milling along one moment, then broken in the exact same spot on the end mill in the next.

So I don’t really get why this is happening. According to HSMAdvisor (which I’ve seen that people here say isn’t suitable for the Nomad 3), there’s no major load on anything with these parameters. Is 20/24k rpm too fast with #274 and gummy C110? Am I not feeding fast enough, and causing work hardening?