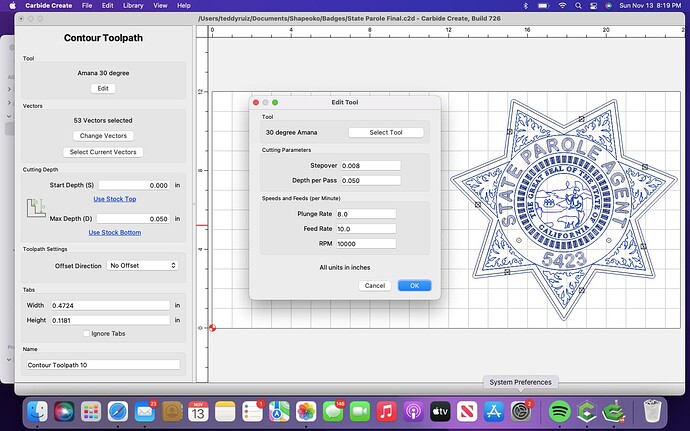

Hey all, I added the Amana 45620 (30 degree, 1/4" shank, .413 cutting length, .0108 tip). Tried to run this file and the bit is coming to just above the workpiece and running just above the workpiece. I’ve reset the zero and am using the bit setter. I’ve tried several different things and had no luck. This is the first bit I’ve added to the library and think I’m just doing it wrong. Any suggestions?

You did not say what machine you have or Z. The Z-plus can have problems going low enough on some machines. If the bit can be jogged down to the spoilboard it is not likely a Z travel issue. So try to jog the bit down to the spoilboard and if it goes down then look at your tool settings. If it will not jog down to the spoilboard then check out the Z axis. Some Z-Plus have their top bearing come out of place and cause the Z to not have full travel.

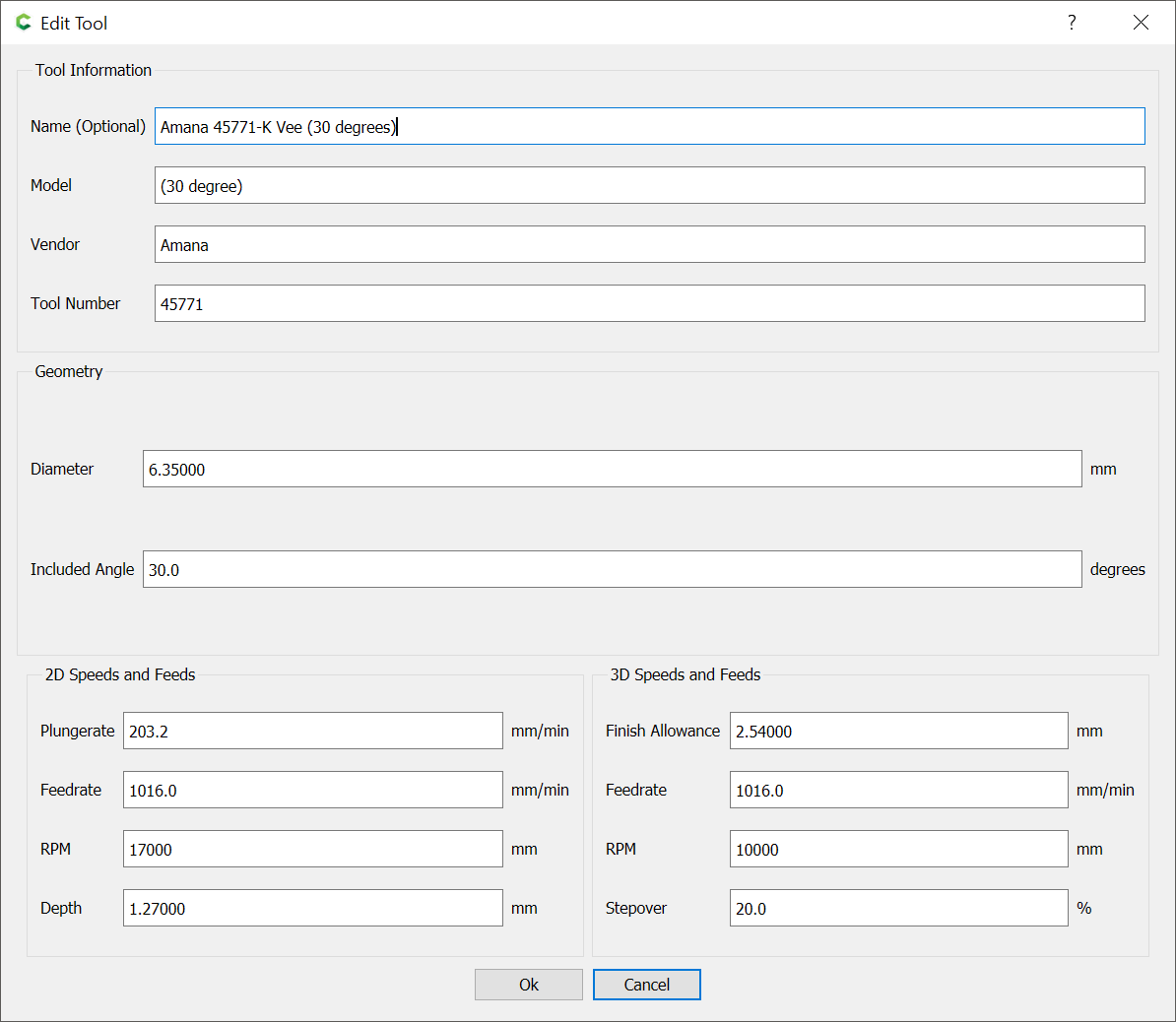

For adding a tool you create a new library and then add the tool. You can then go to the Help menu of CC and choose About and open the data directory and navigate Carbide Create and to the tools folder and find your custom library. You can open the custom tool library in a spreadsheet and look at the properties. When changing data in the file be sure to save as a .csv file and not in the spreadsheet native format.

Here is an example of a key hole tool I added. At the bottom of the table move the line across to see the whole line. Or hover over the table and “Expand Tabs” and slide down to see the whole line.

| number | vendor | model | URL | name | type | diameter | cornerradius | flutelength | shaftdiameter | angle | numflutes | stickout | coating | metric | notes | machine | material | plungerate | feedrate | rpm | depth | cutpower | finishallowance | 3dstepover | 3dfeedrate | 3drpm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 701 | Freud | 70-104 | Keyhole | end | 0.39 | 0 | 0.25 | 0.25 | 0 | 2 | 0 | Shapeoko | Hardwood | 10 | 60 | 16000 | 0.4375 | 0 | 60 | 16000 |

I entered a similar tool as:

Reaching or not reaching the work surface is an interplay between:

- tool length

- router mounting

- where origin is set in the file

- how zero is set relative to the stock

- how one manages all tool changes

Please review:

and

if this doesn’t resolve the issue, please post your .c2d file, step-by-step notes on how you are securing your stock and setting zero relative to it and managing all tool changes and a photo showing an attempt at cutting still in place on the machine and we will do our best to assist.

I’m using the Pro, good catch. I’ll check the Z later today but I’ve not had a problem before. You’re super informative, thank you. Last question, the tip on the blade is .0108. Does that get entered somewhere? The diameter of the shank is .25" and I believe I put that in the right place.

The tip is not entered. You tell CC it is an endmill, Vee or ballmill. The only other choices are engravers like the diamond drag. They may put some of the steep angle vee in the engraver category but the tip is assumed to be a vee. CC does not do advanced geometry on its bits. Currently they do not support tapered mills.

The shape of the end of the bit is not important to CC. Just the depth of cut, stepover and overall depth of cut.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.