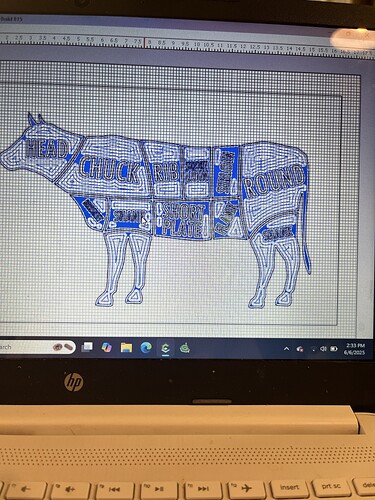

Hey everyone. I recently joined this group and have a question. I make lots of inlay cutting boards and trays and I have a suggestion to what could be added to the software to help tool paths go cleaner and simpler. While I was working on an inlay. I had the advanced v carve option on and the difference between a quarter inch bit pocketing out the inlay and a 1/8 inch bit cutting it out was about 45 minutes to a hour. So I obviously wanted to used the quarter inch bit to save me a lot of time. But the problem is that the quarter inch bit can’t get where the 1/8 inch bit can get which leads to the 60 degree bit that I use to have to pocket clean up more which takes a ton of time. So what if there was a way that I can just run the quarter inch bit first and pocket most of it out, then the 1/8 inch bit gets whatever else the quarter inch bit can’t get to which leads to a much cleaner pocket and my v bit not having to do so much work. But I want to do this all in the same advanced v carve tool path. I know that I could go over the quarter inch tool path with the 8th inch tool path again but that would add on even more hours and I’m just trying to eliminate some time spent. Is this possible and if not I think it would be a great feature added. In the picture below all of the blue is where my quarter inch bit can’t get and my v bit has to clean all that up which leads to a mess.

It’s been asked for several (many) times. (Rest milling in Advanced V-carve)

For now you could offset everything by the effective radius of the cutter at that particular depth, and use a pocket path with rest milling. Then you would have to offset twice that amount, the effective diameter of the cutter, round any corners where the V bit still needs to clean up, and use an advanced v-carve, making sure the clearing tool is too big to cut anything. Then the V-bit will clean up those corners. Or knock those corners out with a chisel after cutting.

2 Likes

I agree that Rest machining in the V Carve toolpath would be an awesome enhancement!!!

This topic was automatically closed after 30 days. New replies are no longer allowed.