Hey is it possible to do an advanced v carve procedure, but instead of using a v bit, used a smaller endmill than the first clearing endmill to do clean up?

Sounds like you’re looking for “Rest Milling”, which is a “Pro” function of the pocket toolpath.

Darn! I have the 3 XXL and just the basic CC software. So this isnt something i can pull off simply by chucking up a smaller endmill huh

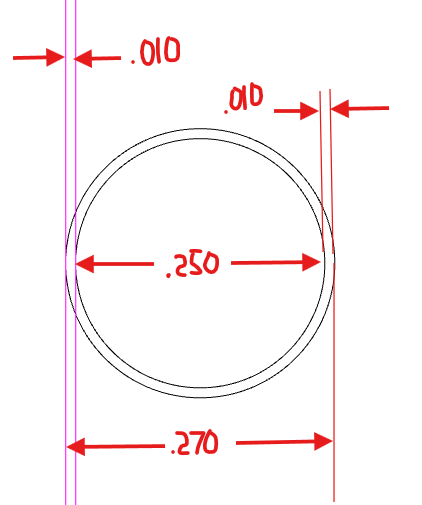

You can do a pocket with the first tool, then an inside contour with the 2nd. If you want clean lines use a rough/finish strategy. To keep the first tool away from the wall, lie and program with a slightly bigger tool. i.e. you have a 1/4" tool and you want to leave 0.010" finish stock. Create a tool that’s 0.270" and program your pocket. Now when you cut with the 0.250" it will leave 0.010" on the wall.

Then your smaller tool will make a smooth profile.

Oh man, I gotta try this. Thanks alot

Hi, Tod.

I don’t understand how telling the machine it is using a 0.270" end mill but cutting with a 0.250" end mill results in 0.010" remaining on the wall. The difference between the two sizes is 0.020". How do we get to 0.01"?

Thanks

0.010" on each side. It’s round!!! ![]()

![]()

Sorry, Tod. I still don’t get it. Is it because the bit has two flutes or something like that?

Regards

Whenever I have trouble grasping how a cut will work out, I draw it up in profile or as viewed from overhead.

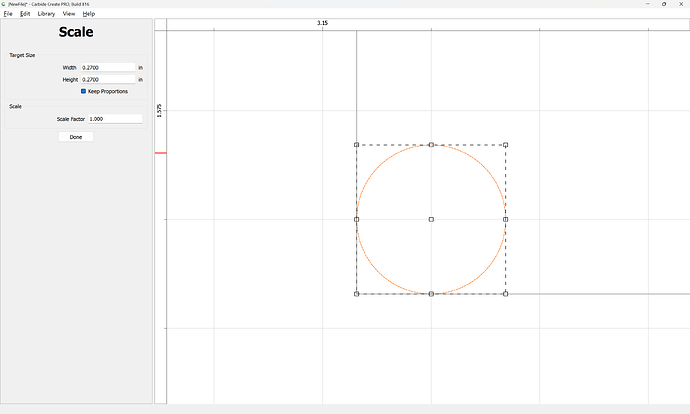

For this case, an 0.27" tool is positioned to cut into a corner:

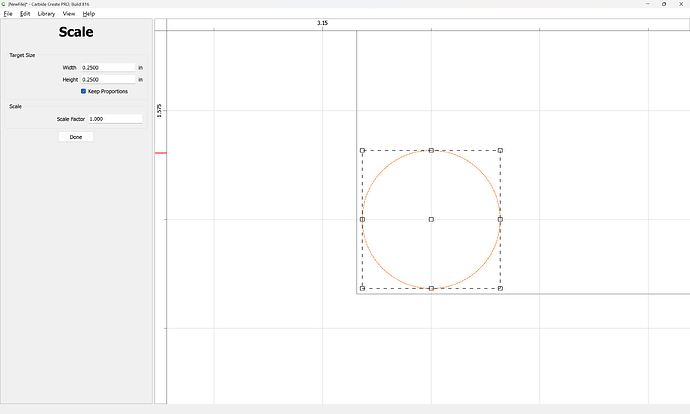

If we then change its diameter to an 0.25" too:

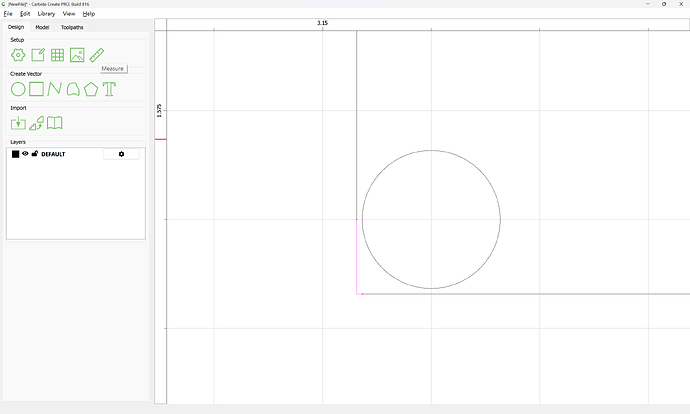

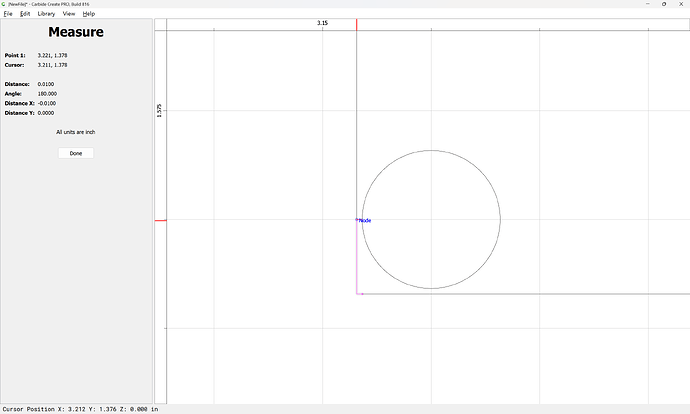

and measure the gap:

we see that it has opened up to 0.01"

Hi, Will.

I did a pencil/paper sketch, and that got me nowhere. Never thought of using the software to create my sketch. I now see, but dimly. I’ll go over your post in detail and probably do my own in the software just because I’m thick-headed. ![]()

Much appreciated,

Allen

AHHH, I did not think about the radius. Got it! Thanks so much.

(Wondering why so many people are up this early–0544 here in the Denver area)