Skipping comment-only line: (Design File:)

Skipping comment-only line: (stockMin:0.00mm, 0.00mm, -19.00mm)

Skipping comment-only line: (stockMax:125.00mm, 125.00mm, 0.00mm)

Skipping comment-only line: (STOCK/BLOCK,125.00, 125.00, 19.00,0.00, 0.00, 19.00)

>>> G90

>>> G21

Skipping comment-only line: (Move to safe Z to avoid workholding)

>>> G53G0Z-5.000

Skipping comment-only line: (Advanced.VCarve.Toolpath.2.-.Pocket)

>>> M05

Skipping comment-only line: (TOOL/MILL,6.35, 0.00, 0.00, 0.00)

>>> M6T320

>>> M03S18000

Skipping comment-only line: (PREPOSITION FOR RAPID PLUNGE)

ok

>>> G0X59.545Y65.545

>>> Z8.000

>>> G1Z-1.016F182.88

>>> Y66.455F914.4

>>> X60.455

>>> Y65.545

>>> X59.545

ok

ok

>>> X56.370Y62.370

>>> Y69.630

ok

[Error] An error was detected while sending 'M6T320': (error:20) Unsupported or invalid g-code command found in block. Streaming has been paused.

[Error] Error while processing response <An error was detected while sending 'M6T320': (error:20) Unsupported or invalid g-code command found in block. Streaming has been paused.>

**** The communicator has been paused ****

**** Pausing file transfer. ****

**** Resuming file transfer. ****

>>> X63.630

ok

>>> Y62.370

ok

>>> X56.370

ok

>>> X53.195Y59.195

ok

>>> Y72.805

>>> X66.805

ok

>>> Y59.195

>>> X53.195

ok

ok

>>> X50.020Y56.020

ok

>>> Y75.980

ok

>>> X69.980

>>> Y56.020

ok

>>> X50.020

ok

ok

>>> X46.845Y52.845

ok

>>> Y79.155

ok

>>> X73.155

>>> Y52.845

ok

>>> X46.845

ok

ok

>>> X43.670Y49.670

ok

>>> Y82.330

ok

>>> X76.330

>>> Y49.670

ok

>>> X43.670

ok

ok

>>> X40.495Y46.495

ok

>>> Y85.505

ok

>>> X79.505

>>> Y46.495

ok

>>> X40.495

ok

>>> Z8.000

ok

ok

>>> G0X59.545Y65.545

ok

>>> Z-0.508

ok

>>> G1Z-2.032F182.88

ok

ok

>>> Y66.455F914.4

ok

>>> X60.455

ok

>>> Y65.545

>>> X59.545

ok

ok

>>> X56.370Y62.370

ok

>>> Y69.630

ok

>>> X63.630

ok

>>> Y62.370

ok

>>> X56.370

ok

>>> X53.195Y59.195

ok

>>> Y72.805

>>> X66.805

ok

>>> Y59.195

>>> X53.195

>>> 0x91

>>> 0x91

>>> 0x91

>>> 0x91

ok

>>> 0x91

>>> 0x91

>>> 0x91

>>> 0x91

>>> 0x91

>>> 0x91

ok

>>> X50.020Y56.020

ok

>>> Y75.980

ok

>>> X69.980

>>> Y56.020

ok

>>> X50.020

ok

ok

>>> X46.845Y52.845

ok

>>> Y79.155

ok

>>> X73.155

>>> Y52.845

ok

>>> X46.845

ok

ok

>>> X43.670Y49.670

ok

>>> Y82.330

ok

>>> X76.330

>>> Y49.670

ok

>>> X43.670

ok

ok

>>> X40.495Y46.495

ok

>>> Y85.505

ok

>>> X79.505

>>> Y46.495

ok

>>> X40.495

ok

>>> Z8.000

ok

ok

>>> G0X59.545Y65.545

ok

>>> Z-0.762

ok

>>> G1Z-2.286F182.88

ok

ok

>>> Y66.455F914.4

ok

>>> X60.455

ok

>>> Y65.545

>>> X59.545

ok

ok

>>> X56.370Y62.370

ok

>>> Y69.630

ok

>>> X63.630

ok

>>> Y62.370

ok

>>> X56.370

ok

>>> X53.195Y59.195

ok

>>> Y72.805

>>> X66.805

ok

>>> Y59.195

>>> X53.195

ok

ok

>>> X50.020Y56.020

ok

>>> Y75.980

ok

>>> X69.980

>>> Y56.020

ok

>>> X50.020

ok

ok

>>> X46.845Y52.845

ok

>>> Y79.155

ok

>>> X73.155

>>> Y52.845

>>> 0x90

ok

>>> X46.845

ok

ok

>>> X43.670Y49.670

ok

>>> Y82.330

ok

>>> X76.330

>>> Y49.670

ok

>>> X43.670

ok

ok

>>> X40.495Y46.495

ok

>>> Y85.505

ok

>>> X79.505

>>> Y46.495

ok

>>> X40.495

ok

>>> Z8.000

Skipping comment-only line: (Advanced.VCarve.Toolpath.2.-.Vee)

>>> M05

Skipping comment-only line: (Move to safe Z to avoid workholding)

ok

ok

>>> G53G0Z-5.000

Skipping comment-only line: (TOOL/MILL,0.03, 0.00, 10.00, 30.00)

ok

>>> M6T302

>>> M03S18000

Skipping comment-only line: (PREPOSITION FOR RAPID PLUNGE)

ok

ok

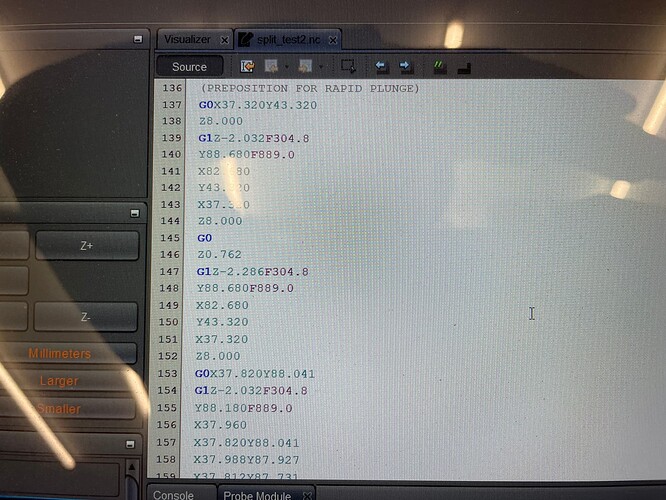

>>> G0X37.320Y43.320

ok

>>> Z8.000

ok

ok

>>> G1Z-2.032F182.88

ok

>>> Y88.680F533.4

ok

>>> X82.680

ok

>>> Y43.320

ok

>>> X37.320

ok

>>> Z8.000

>>> G0

ok

ok

>>> Z0.762

[Error] An error was detected while sending 'M6T302': (error:20) Unsupported or invalid g-code command found in block. Streaming has been paused.

[Error] Error while processing response <An error was detected while sending 'M6T302': (error:20) Unsupported or invalid g-code command found in block. Streaming has been paused.>

**** The communicator has been paused ****

**** Pausing file transfer. ****

**** Canceling file transfer. ****

ok

Grbl 1.1f ['$' for help]

>>> $$

$0 = 10 (Step pulse time, microseconds)

$1 = 255 (Step idle delay, milliseconds)

$2 = 0 (Step pulse invert, mask)

$3 = 6 (Step direction invert, mask)

$4 = 0 (Invert step enable pin, boolean)

$5 = 0 (Invert limit pins, boolean)

$6 = 0 (Invert probe pin, boolean)

$10 = 255 (Status report options, mask)

$11 = 0.020 (Junction deviation, millimeters)

$12 = 0.010 (Arc tolerance, millimeters)

$13 = 0 (Report in inches, boolean)

$20 = 1 (Soft limits enable, boolean)

$21 = 1 (Hard limits enable, boolean)

$22 = 1 (Homing cycle enable, boolean)

$23 = 0 (Homing direction invert, mask)

$24 = 100.000 (Homing locate feed rate, mm/min)

$25 = 2000.000 (Homing search seek rate, mm/min)

$26 = 25 (Homing switch debounce delay, milliseconds)

$27 = 3.000 (Homing switch pull-off distance, millimeters)

$30 = 1000 (Maximum spindle speed, RPM)

$31 = 0 (Minimum spindle speed, RPM)

$32 = 0 (Laser-mode enable, boolean)

$100 = 40.000 (X-axis travel resolution, step/mm)

$101 = 40.000 (Y-axis travel resolution, step/mm)

$102 = 40.000 (Z-axis travel resolution, step/mm)

$110 = 10000.000 (X-axis maximum rate, mm/min)

$111 = 10000.000 (Y-axis maximum rate, mm/min)

$112 = 5000.000 (Z-axis maximum rate, mm/min)

$120 = 400.000 (X-axis acceleration, mm/sec^2)

$121 = 400.000 (Y-axis acceleration, mm/sec^2)

$122 = 400.000 (Z-axis acceleration, mm/sec^2)

$130 = 835.000 (X-axis maximum travel, millimeters)

$131 = 430.000 (Y-axis maximum travel, millimeters)

$132 = 100.000 (Z-axis maximum travel, millimeters)

ok

>>> $G

[GC:G0 G54 G17 G21 G90 G94 M5 M9 M56 T0 F0 S0]

ok

>>> $J=G21G91Z3F2007

ok

>>> $J=G21G91Z3F2007

ok

>>> $J=G21G91Z3F2007

ok

>>> $J=G21G91Z3F2007

ok

>>> $J=G21G91Z3F2007

ok

>>> $J=G21G91Z3F2007

ok

>>> $J=G21G91Z3F2007

ok

>>> $J=G21G91Z3F2007

ok

>>> $J=G21G91Z3F2007

ok

>>> $J=G21G91Z3F2007

ok

>>> $J=G21G91Z3F2007

ok

>>> $J=G21G91X-10F2007

ok

>>> $J=G21G91X-10F2007

ok

>>> $J=G21G91Z-3F2007

ok

>>> $J=G21G91Z-3F2007

ok

>>> $J=G21G91Z-3F2007

ok

>>> $J=G21G91Z-3F2007

ok

>>> $J=G21G91Z-3F2007

ok

>>> $J=G21G91Z-3F2007

ok

>>> $J=G21G91Z-3F2007

ok

>>> $J=G21G91Z-3F2007

ok

>>> $J=G21G91Z-3F2007

ok

>>> G10 L20 P1 Z0

ok

>>> G91 G21

>>> G21 G91 G49

>>> G38.2 Z-10 F250

>>> G91 G21

ok

ok

[PRB:-332.500,-296.500,-42.025:1]

>>> G91 G21 G0 Z1.0

>>> G91 G21

>>> G21 G91 G49

>>> G38.2 Z-10 F100

ok

>>> G91 G21

ok

ok

ok

ok

[PRB:-332.500,-296.500,-42.000:1]

ok

ok

>>> G90 G21 G0 Z0.0

>>> G91 G21

ok

ok

>>> G10 L20 P1 Z26.175

ok

>>> G91 G21

ok

>>> G21G90G91.1G94G54G17

ok

>>> G0Z8.0

>>> G0X37.32Y43.32

>>> M3S18000.0F914.4

>>> G1Z-5.0

>>> F914.4S18000.0G0Z8.000

>>> G1Z-2.032F182.88

>>> Y88.680F533.4

>>> X82.680

>>> Y43.320

>>> X37.320

ok

>>> Z8.000

>>> G0

ok

>>> Z0.762

ok

>>> G1Z-2.286F182.88

ok

>>> Y88.680F533.4

ok

>>> X82.680

>>> Y43.320

>>> X37.320

ok

>>> Z8.000

ok

>>> G0X37.820Y88.041

ok

>>> G1Z-2.032F182.88

ok

ok

>>> Y88.180F533.4

ok

>>> X37.960

ok

ok

ok

>>> X37.820Y88.041

ok

>>> X37.988Y87.927

ok

>>> X37.812Y87.731

ok

ok

>>> X37.620Y87.474

ok

>>> Y88.380

ok

>>> X38.524

ok

>>> X38.240Y88.164

>>> X37.988Y87.927

ok

>>> X38.133Y87.789

ok

ok

>>> X37.918Y87.543

>>> 0x91

>>> 0x91

>>> 0x91

ok

>>> X37.726Y87.273

>>> 0x91

ok

>>> X37.564Y86.988

ok

>>> X37.420Y86.662

>>> Y88.580

ok

>>> X39.339

ok

ok

>>> X38.987Y88.424

ok

>>> X38.706Y88.260

ok

>>> X38.372Y88.013

ok

>>> X38.133Y87.789

>>> Z8.000

ok

ok

>>> G0X37.820Y88.041

>>> Z0.762

ok

>>> G1Z-2.286F182.88

ok

ok

>>> Y88.180F533.4

ok

>>> X37.960

ok

>>> X37.820Y88.041

ok

>>> X37.988Y87.927

ok

>>> X37.812Y87.731

ok

>>> X37.620Y87.474

ok

>>> Y88.380

>>> X38.524

ok

ok

>>> X38.240Y88.164

>>> X37.988Y87.927

ok

>>> X38.133Y87.789

ok

ok

>>> X37.918Y87.543

ok

>>> X37.726Y87.273

ok

>>> X37.564Y86.988

ok

>>> X37.420Y86.662

>>> Y88.580

ok

>>> X39.339

ok

ok

>>> X38.987Y88.424

ok

>>> X38.706Y88.260

ok

>>> X38.372Y88.013

ok

>>> X38.133Y87.789

>>> Z8.000

ok

ok

>>> G0X37.820Y43.820

ok

>>> G1Z-2.032F182.88

ok

>>> Y43.960F533.4

ok

ok

>>> X37.959Y43.820

>>> X37.820

ok

>>> X37.620Y43.620

ok

>>> Y44.524

ok

>>> X37.836Y44.240

ok

>>> X38.073Y43.988

ok

>>> X38.269Y43.812

ok

>>> X38.526Y43.620

>>> X37.620

ok

>>> X37.420Y43.420

ok

>>> Y45.339

ok

>>> X37.576Y44.987

ok

>>> X37.740Y44.706

ok

ok

>>> X37.987Y44.372

ok

>>> X38.153Y44.191

ok

>>> X38.395Y43.968

ok

>>> X38.727Y43.726

ok

>>> X39.012Y43.564

ok

>>> X39.338Y43.420

ok

>>> X37.420

ok

>>> Z8.000

ok

>>> G0X37.820Y43.820

>>> Z0.762

ok

ok

>>> G1Z-2.286F182.88

ok

>>> Y43.960F533.4

ok

>>> X37.959Y43.820

>>> X37.820

ok

>>> X37.620Y43.620

ok

>>> Y44.524

ok

>>> X37.836Y44.240

ok

ok

>>> X38.073Y43.988

>>> X38.269Y43.812

ok

ok

>>> X38.526Y43.620

>>> X37.620

ok

>>> X37.420Y43.420

ok

>>> Y45.339

ok

>>> X37.576Y44.987

ok

>>> X37.740Y44.706

ok

ok

>>> X37.987Y44.372

ok

>>> X38.153Y44.191

ok

>>> X38.395Y43.968

ok

>>> X38.727Y43.726

ok

>>> X39.012Y43.564

ok

>>> X39.338Y43.420

ok

>>> X37.420

ok

>>> Z8.000

ok

>>> G0X82.040Y43.820

ok

>>> G1Z-2.032F182.88

ok

ok

>>> X82.180Y43.959F533.4

>>> Y43.820

ok

>>> X82.040

ok

>>> X81.898Y43.961

ok

>>> X82.188Y44.269

ok

>>> X82.380Y44.526

ok

>>> Y43.620

ok

>>> X81.476

ok

>>> X81.898Y43.961

>>> X81.747Y44.093

ok

>>> X82.032Y44.395

ok

>>> X82.228Y44.658

ok

ok

>>> X82.436Y45.012

ok

>>> X82.580Y45.338

>>> Y43.420

ok

>>> X80.661

ok

>>> X81.013Y43.576

ok

ok

>>> X81.225Y43.696

ok

>>> X81.495Y43.881

ok

>>> X81.747Y44.093

>>> Z8.000

ok

ok

>>> G0X82.040Y43.820

>>> Z0.762

ok

>>> G1Z-2.286F182.88

ok

ok

>>> X82.180Y43.959F533.4

ok

>>> Y43.820

ok

>>> X82.040

ok

>>> X81.898Y43.961

ok

>>> X82.188Y44.269

ok

>>> X82.380Y44.526

ok

>>> Y43.620

>>> X81.476

ok

ok

>>> X81.898Y43.961

>>> X81.747Y44.093

ok

>>> X82.032Y44.395

ok

>>> X82.228Y44.658

ok

ok

>>> X82.436Y45.012

ok

>>> X82.580Y45.338

>>> Y43.420

ok

>>> X80.661

ok

>>> X81.013Y43.576

ok

ok

>>> X81.225Y43.696

ok

>>> X81.495Y43.881

ok

>>> X81.747Y44.093

>>> Z8.000

ok

ok

>>> G0X82.116Y88.104

ok

>>> G1Z-2.032F182.88

ok

ok

>>> X82.041Y88.180F533.4

ok

>>> X82.180

>>> Y88.040

ok

>>> X82.116Y88.104

ok

>>> X81.990Y87.949

ok

>>> X81.731Y88.188

ok

ok

>>> X81.474Y88.380

>>> X82.380

ok

>>> Y87.476

>>> X82.164Y87.760

ok

>>> X81.990Y87.949

ok

>>> X81.847Y87.809

ok

ok

>>> X81.605Y88.032

ok

>>> X81.273Y88.274

ok

>>> X80.988Y88.436

ok

>>> X80.662Y88.580

>>> X82.580

ok

>>> Y86.661

ok

ok

>>> X82.424Y87.013

ok

>>> X82.260Y87.294

ok

>>> X82.013Y87.628

ok

>>> X81.847Y87.809

>>> Z8.000

ok

ok

>>> G0X82.116Y88.104

>>> Z0.762

ok

>>> G1Z-2.286F182.88

ok

ok

>>> X82.041Y88.180F533.4

ok

>>> X82.180

ok

>>> Y88.040

ok

>>> X82.116Y88.104

ok

>>> X81.990Y87.949

ok

>>> X81.731Y88.188

ok

>>> X81.474Y88.380

>>> X82.380

ok

ok

>>> Y87.476

>>> X82.164Y87.760

ok

>>> X81.990Y87.949

ok

>>> X81.847Y87.809

ok

ok

>>> X81.605Y88.032

ok

>>> X81.273Y88.274

ok

>>> X80.988Y88.436

ok

>>> X80.662Y88.580

>>> X82.580

ok

>>> Y86.661

ok

ok

>>> X82.424Y87.013

ok

>>> X82.260Y87.294

ok

>>> X82.013Y87.628

ok

>>> X81.847Y87.809

>>> Z8.000

ok

ok

>>> G0X36.000Y42.000

ok

>>> G1Z0.000F182.88

ok

ok

>>> X37.320Y43.320Z-2.032F533.4

ok

>>> Z8.000

ok

>>> G0X36.000Y42.000

ok

>>> G1Z0.000F182.88

ok

ok

>>> X37.320Y43.320Z-2.286F533.4

ok

>>> Z8.000

>>> G0Y88.680

ok

ok

>>> G1Z-2.032F182.88

>>> X36.000Y90.000Z0.000F533.4

ok

>>> Z8.000

ok

>>> G0X37.320Y88.680

ok

ok

>>> G1Z-2.286F182.88

>>> X36.000Y90.000Z0.000F533.4

ok

>>> Z8.000

ok

ok

>>> G0X84.000Y42.000

ok

>>> G1Z0.000F182.88

ok

>>> X82.680Y43.320Z-2.032F533.4

ok

>>> Z8.000

ok

>>> G0X84.000Y42.000

ok

>>> G1Z0.000F182.88

ok

>>> X82.680Y43.320Z-2.286F533.4

ok

>>> Z8.000

>>> G0Y88.680

ok

ok

>>> G1Z-2.032F182.88

>>> X84.000Y90.000Z0.000F533.4

ok

>>> Z8.000

ok

>>> G0X82.680Y88.680

ok

ok

>>> G1Z-2.286F182.88

>>> X84.000Y90.000Z0.000F533.4

ok

>>> Z8.000

ok

>>> M02

ok

ok

ok

ok

ok

ok

ok

[MSG:Pgm End]

ok

**** Finished sending file in 00:01:41 ****