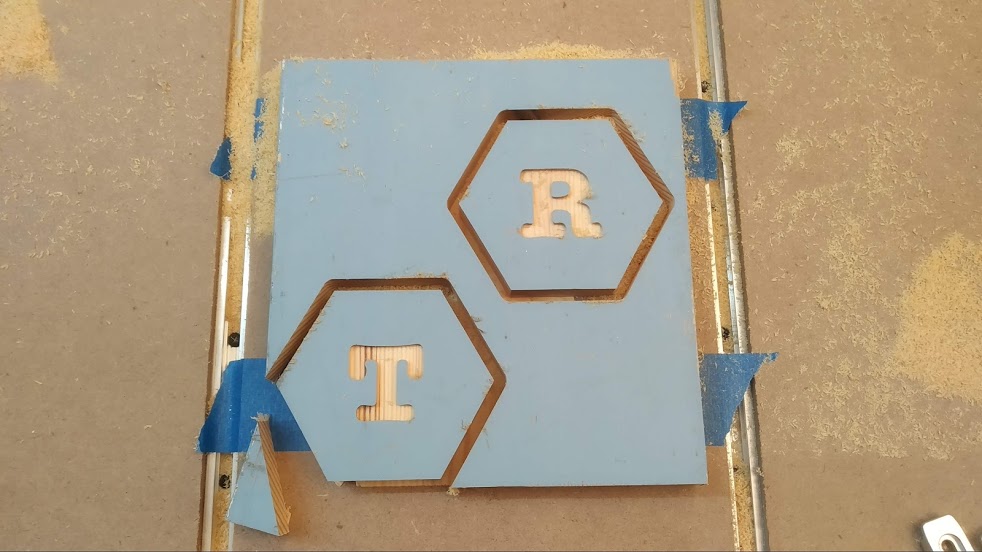

I bought my XXL in 2019 and had a few issues getting started. In all cases, they were my fault - either not understanding CNCs (this was my first) or not following my own workflow. It took a while to have confidence. However, the machine works; it works well; and it’s pretty predictable and repeatable. That’s the big thing you ask for. Installation is something you need to go slowly and follow, step by step. There are lots of videos on YouTube to watch AFTER you watch the Carbide ones. I love my SO…but it’s not always a smooth experience…

The biggest knock on the product for me is probably the biggest strength of the product for others. I’m sure it causes a problem for Carbide as well: There are two types of clients for this product - Those who want to tinker and modify and DIY - and those who are looking for a low-cost alternative for a complete CNC solution - I fall in the latter category, and the company seems to think of itself more in the former; it caters to - and supports well - the tinkerer. Don’t get me wrong, support is great and helpful - but, unless you’re really familiar with these types of machines, you’re going to need to call support a few times. I’ve never had to call support for my SawStop tablesaw, my Powermatic Jointer, my JTech laser, or even my Leigh Jigs (to be closer to routers) — but the Shapeoko has me visiting this community every day, and support multiple times in the past year.

As a consequence of the DIY-mentality, you see things like the documentation not being good and tending to lag behind the products. Even the videos will fall short - or be on back-leveled products that don’t look like what you have in front of you. @Julien 's gitbook is a bible…but unofficial and lagging product releases (naturally). Products come out without any real cycle, kind of out of nowhere and without a published road-map. There are almost too many options to do the same thing (Z’s, belts, rollers, switches - for example). The software is free (which is great), but then its largely undocumented and updates are unstructured. It’s a normal occurrence for Carbide themselves to send you to Fusion, Inkscape or some other software to accomplish tasks. Contrast this with Lightburn. Functional upgrades are often not purchased, but rather treated as DIY projects - wire this, swap out that, build a support, print a part, etc… This flexibility makes the product a gem for engineers - but for those who would rather not tinker, but are looking for low-cost function, there’s often a learning curve and you find yourself holding a soldering iron more than you might expect to!

I now feel comfortable with my Shapeoko. I’m still struggling with the 3D Modeling features of CC pro - and I wish there was actual documentation of the parameters…but there isn’t. You can view some videos, and draw your own conclusions as to how things are intended to work (DIY again). That’s been the basic theme - and frankly, this community is essential to anyone using the products. Thank goodness for the friends here.

For me, I could have used a bit of expectation setting before diving in - that would have reduced my anxiety and frustration up front. As I say, I’m comfortable now and can rely on my Shapeoko as a tool in my shop for my professional pieces…but it’s a process - which you ought to know up front.

is one of expectations setting. Recognizing that the lower price point will draw the interest of non-DIY’ers is something Carbide can either cater to, or communicate for expectation.

is one of expectations setting. Recognizing that the lower price point will draw the interest of non-DIY’ers is something Carbide can either cater to, or communicate for expectation.