Thanks @WillAdams!

Thanks @Julien! I wish I wouldn’t have taken some pictures in the process. I almost didn’t make it, since the first try of each part broke. For feeds and speeds I basically just used the feeds and speeds for pine from the Shapeoko cheat sheet. I did this because I started off by making a test of the top part in pine. I basically just kept the same program from Fusion 360 and turned down the feed percentage in Carbide Motion. Definitely not the best way to accomplish things, but for a newbie that needed to get something done fast, it seemed to work ok.

It requires you to sit and watch the machine ALL the time when it’s running. But I think I would have had to do that anyway since it’s my first project.

For the big rounded corners on the box (which I made as squircles and not fully rounded corners), the rounded corners in the pocket of the box and the rounding of the “buttons” made from wenge, I used a 6mm rounded cutter (https://www.cncfraises.fr/carbures-2-dents-hemispherique/121-fc2ds600.html).

For making all the pockets I used a 2 flute straight cutter (https://www.cncfraises.fr/carbure-helicoidale-2-dents-queue-6-00/67-fc2dh600.html). I think it might be beneficial to use a downcut endmill the next time. I don’t know if there’s a quicker way to cuts such deep pockets? That part of the program definitely took the longest time.

I used the same endmill to face off the surface. I think using a proper facing endmill might be better to use next time.

For cutting the rest of the wenge, I used a 1/8" 2 flute straight cutter (https://www.cncfraises.fr/fraises-carbures-helicoidales-2-dents/127-fraise-2-dents-317-mm-carbure-helicoidale-xl.html). That seemed to work time.

Thanks @GJM! The wenge was surprisingly easy to cut. The buttons are cut with the grains pointing upwards and that actually worked better than the mirror frame where the wenge was cut with the grains pointing along the Shapeoko. I can highly recommend cutting wenge with the grains pointing upwards. The finish it has coming straight from the machine is really nice and the grains look great when cut with a radius.

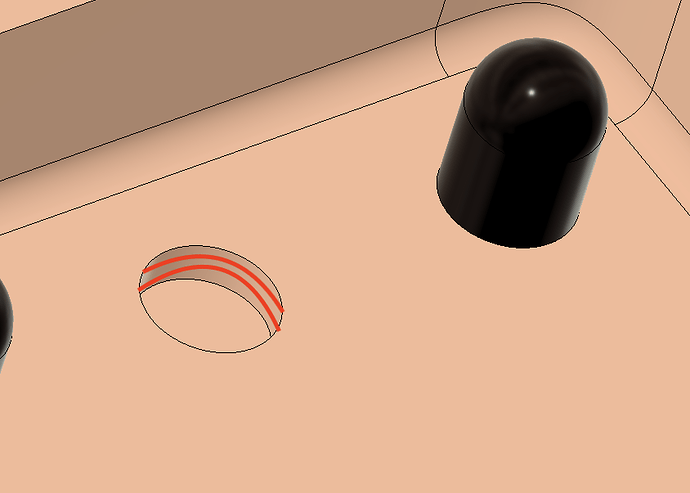

One thing that I’d like to improve on (I think I’ll end up making a couple more) is to make the buttons threaded instead of using glue. I see that CNCFraises have threaded cutters (https://www.cncfraises.fr/236-fraises-a-fileter) that seem to work on wood as well. With those I guess I would be able to make M8 threads in the box:

I’m not sure how I would be able to make M8 threads in the wenge button. Any suggestions @Julien? When I search the community, the issue of making nuts and bolts in wood seem to only have come up once (Making wooden bolts and nuts?) and it didn’t seem like a good solution have been found.