I’m about to make my first big project on my new Shapeoko and would love some practical advice on how to do it. I’ve had great luck asking in this forum before (Best place to buy cutters in Europe (Denmark), Designing a soundproof'ish enclosure for my new SO3), so I thought I’d ask again. I’ve only just started to dive into CNC’ing, so I’m kind of jumping into the deep end of the pool with this project.

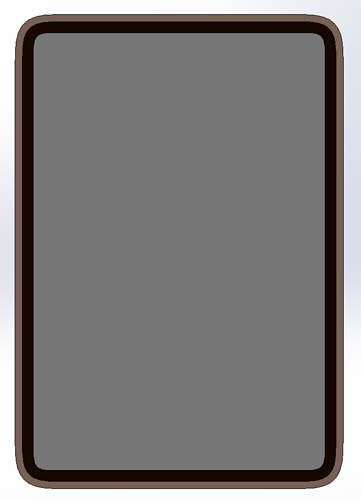

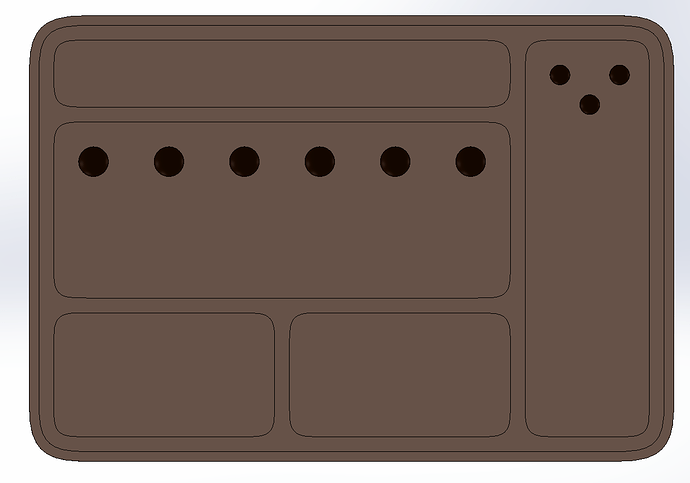

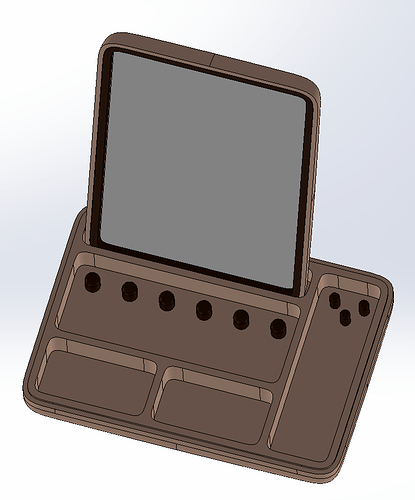

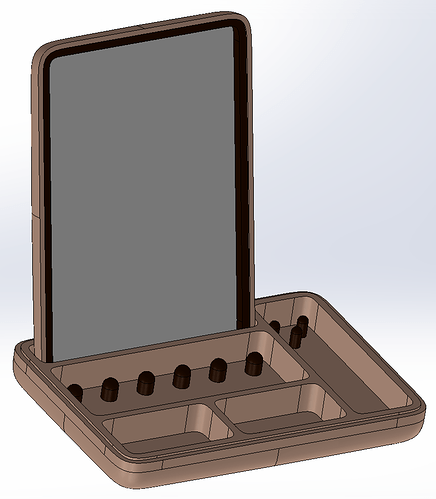

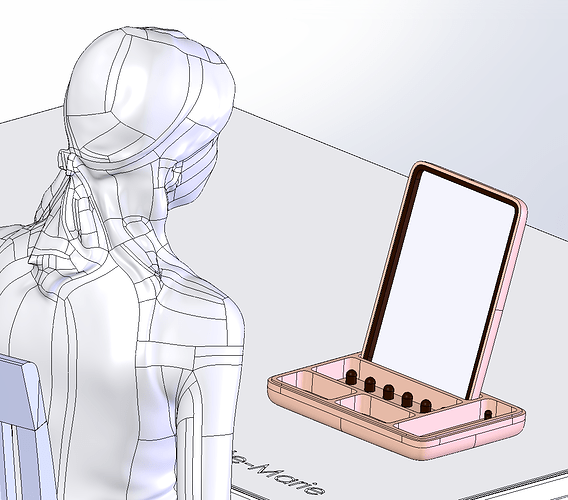

The project I’m planning on doing is a jewelry box made from oak and wenge:

Which kind of endmills would you use for this project and which endmills would you use for which parts? Is it really necessary to use a downcut endmill for the pockets in the wood or can I just sand the bad edges?

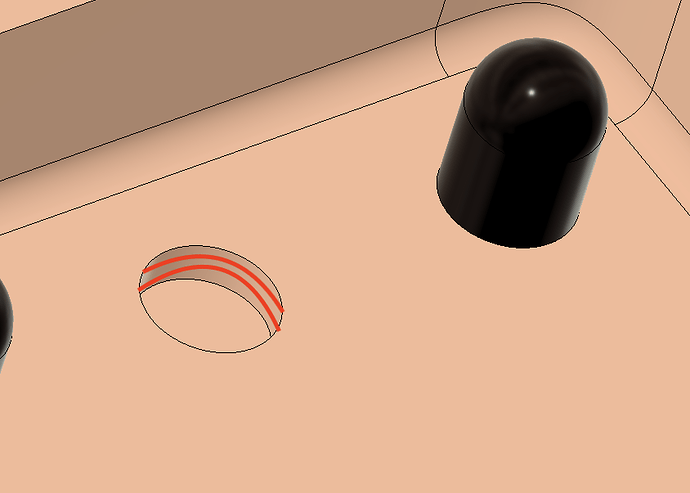

I’m making the top and bottom base in oak and the ring-holders in wenge. I’m planning on making a 4mm cut in the base and then glue the holders in the whole. Diameter would you make the hole and the holder? What should the spacing be between them?

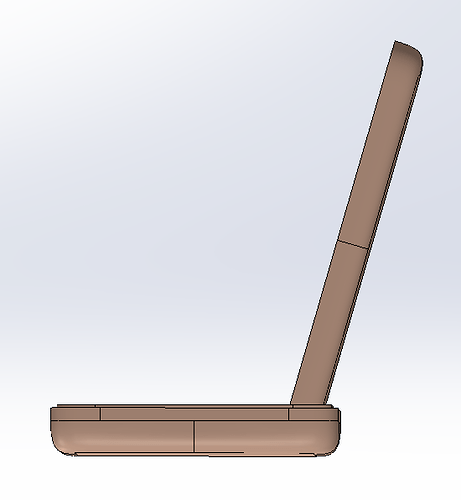

The top and bottom need to be cut on both sides. Pockets on the inside and rounded corners on the outside. How would I deal with cutting both sides of a material?

Would you do anything differently in the design to make it easier to produce? Do you foresee any hickups that I haven’t seen? Any other advice or opinions?

.

.