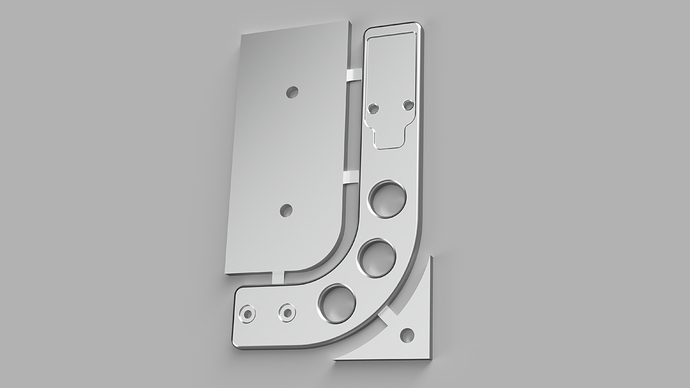

Fusion 360 File

Mist system on Amazon

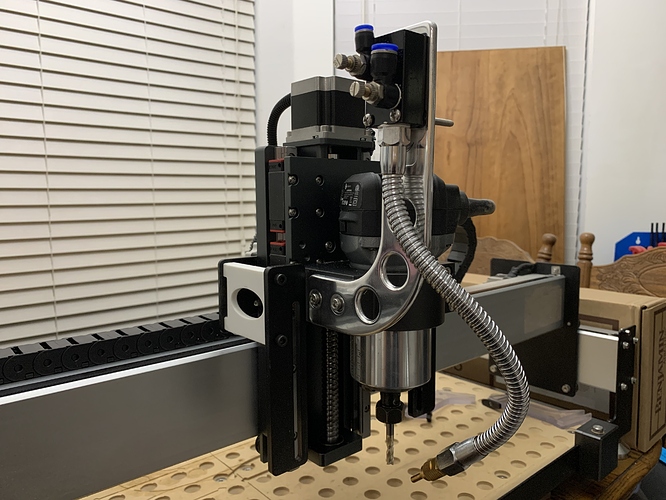

Now that’s a proper bracket! Go Big or Go Home!

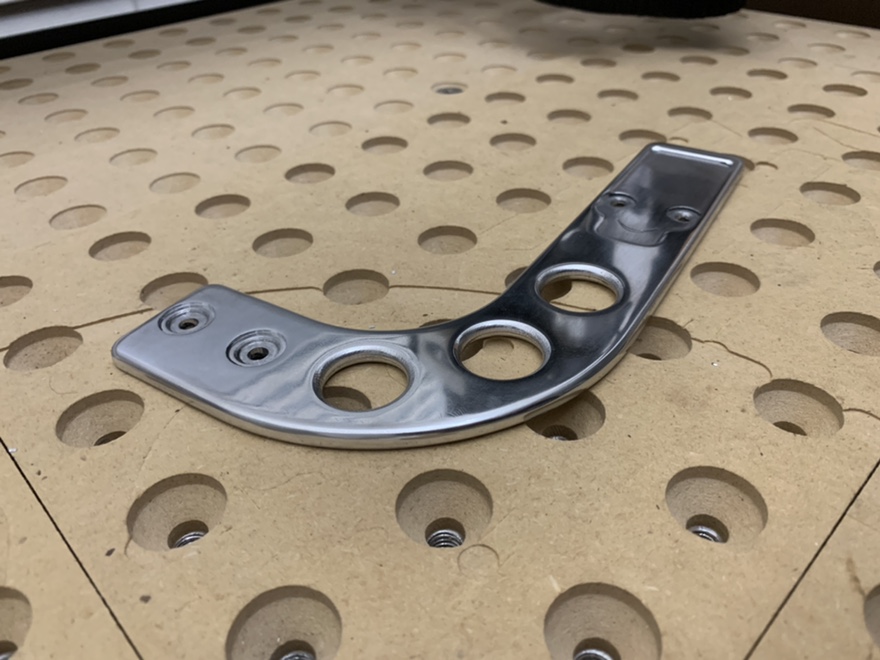

There’s something wrong with your finishing toolpaths…it looks smooth or something.

Can you post your speeds and feeds and material type.![]()

I assumed some post processing I.e. polishing?

I love this, it looks great. You can also mount a mister directly to the side too

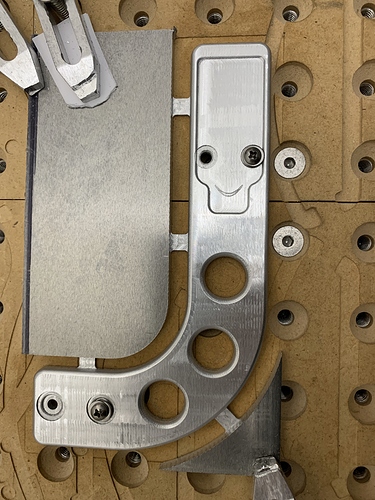

Thanks guys, I am very happy for my first Aluminum piece (6061). Everything is there in Fusion 360 it is set for public download. You have to download the file from the fusion website and open it in 360 it to see all the tool paths on PC, or download the Fusion360 phone app I think. Both are free and coolest software ever!

I plan to design a second bracket that will stay stationary and work with the Suckit dust boot soon. It will most likely bolt to the 2 Suckit ear mount bolts, and aim at the end mill from the back to blow chips toward the vacuum port.

I used a small paint brush to apply thread cutting fluid which worked amazing. Left the piece with a oiled slippery surface and minimum cleanup.

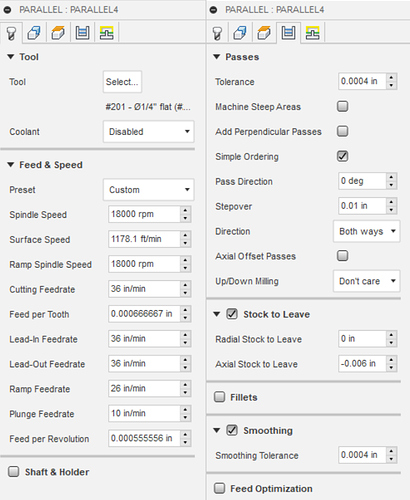

It came out pretty smooth, I did finishing parallels with a 201. I went 12 steps up from 800 to 16000 grit then polished it on a buffing wheel. Here it is before sanding and polishing:

I protected all the toolpaths after finishing the top, and added a piece of MDF and cut a jig on the same homing after completion and finished the back side,after contouring all the bevels, by trading off mount screws and running 2 parallel operations to finish.

Just a warning, I tried to get help on feeds and speeds and ended up just giving my best guess, so check the feeds and speeds before using. The chips seemed pretty small and it made some dust on finishing passes. If you could get someone with experience to review them, it would be best. I will change variables if necessary. My tools do not seem damaged, and I think it came out pretty good!

I am ready to start making parts to finish my car! Screw wood!

My last aluminum brackets I made by hand, came out about the same but took 4 days, only I was covered in aluminum dust and it was all over the garage haha… This is what I used 3 months ago before I got the Shapeoko, and the results.

Needless to say I am very happy with my Shapeoko!

Luke, I made the bracket because the snout on the mister I ordered is way too long to bolt directly to the spindle mount. I put it where it is so you had access to power switch. There is no way I could make it work with out an extension bracket.

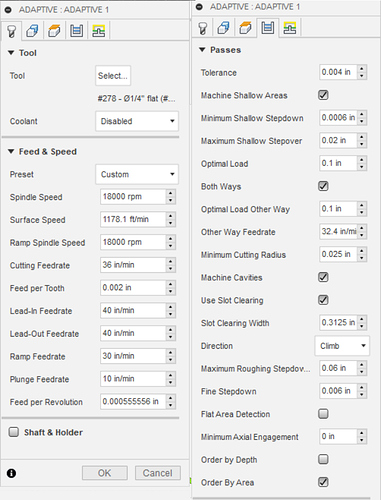

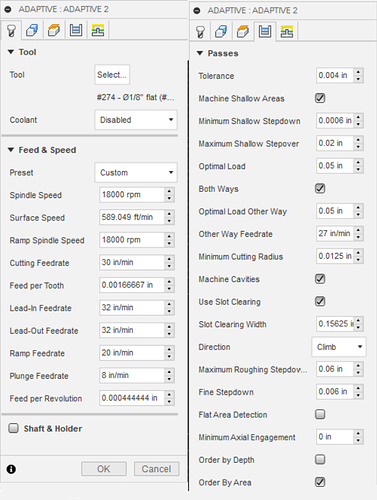

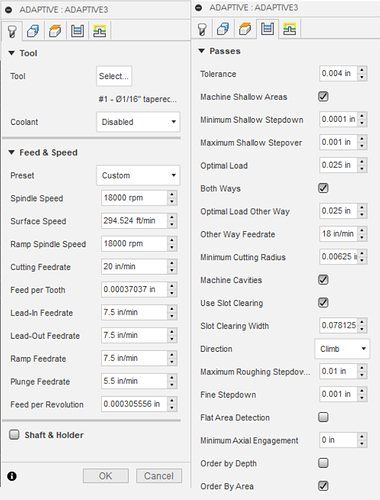

Maybe I was taking the wrong approach asking for help expecting someone to download my files, here are the feeds and speeds, I would very much appreciate assistance if someone with experience could take the time to look at these numbers and give advice on specific tools and operations. I am sure it will help others in the future and I promise to make more stuff for the Shapeoko and post the files for free.

Thank you very much!

Tool 1 Carbide 3D-278Z Quarter Inch Single Flute

Is .06 too much Max Roughing Stepdown for a 274 1/8 single flute?

Tool 2 Carbide 3D-274Z Eighth Inch Single Flute

I recently ordered the 2MM Single Flute from C3D I assume it will be better then the 46290 for small cuts?

Tool 3 Amana 46290 One Sixteenth Flat

This is a very long tool and I was getting some chatter. I need to find something shorter. Any advice is appreciated.

Tool 4 Amana 46295 One Eighth Ball

Tool 5 Carbide 3D 201Z Quarter Inch Flat

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.