Which is why I think Winston is the best resource currently for stock-Shapeoko aluminum milling. He has very few mods on his machine and has good recipes that he shares in his videos. I started there to get comfortable with aluminum and an increasing gradually in my aggressiveness.

I agree that Winston’s video are a place to start and if this is the only thing we have, I guess it is a start but let me give my constructive criticism. Winston’s videos are interesting well edited and to the point but they relatively short, with tight edit they skip some details, in most (not the last one on aluminum), the settings are quickly mentioned. He uses F360 (good software but not for most newbies) and designs something in 3D with intricate tool paths. The video mentions what was done they do not how to do it.

In contrast, John Clark’s YouTube videos (for wood and engraving), as an example as he maybe not as well known, take you from concept to finish product showing you how to do it using the basic tools providing tips and tricks along the way. This IMO would be the type of instruction that would be beneficial to aluminum newbies. Unfortunately, I guess he’s not milling aluminum yet.

I guess the difficulty is coming up with learning content that is not too obscure but still detailed enough, when there are so any different kind of Shapeoko users, that have different expectations…Winston’s videos have always been great and are getting better each time. But I agree that the missing part in all the content out there is a kind of learning roadmap, so as not to feel lost/overwhelmed in the first months/year.

This being said, this forum is probably the next best thing !

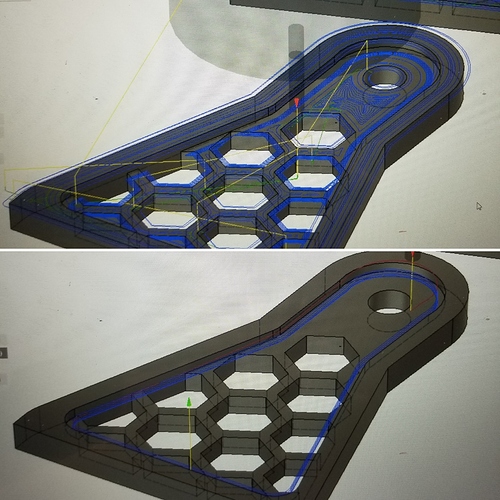

Here is a photo of the difference in horizontal VS contour. The horizontal is calculated in Fusion with an offsetting path and that might be what you are seeing.

Horizontal- its only really useful for finishing on the flat areas of your part. I like to use a manual stepover similar to what opt load I use for adaptive on the same tool. Also morph spiral option usually brings out the best surface finish.

Now I’m still a newb at fusion and only self and youtube taught so there might be better ways to use these paths and actually dial in a comp if you really need it.

@luc.onthego

The information is out there and if you really want to cut aluminum it’s not hard. Winston is doing a fantastic job and imo Carbide is already going out of their way to provide support for a material the machine wasn’t really designed for. The shapeoko runs g code like a large machine. Design your parts like they being made by a large machine, fixture your parts like a large machine, adjust cutting loads to what your personal machine likes.

You’re ready to cut metal now, buy some $7 hss Amana bits and just do it. Mistakes will be your best teacher. Its almost impossible to hurt the s3, you can afford to be brave  (maybe have some spare v wheels)

(maybe have some spare v wheels)

Wouldn’t this be a great thing to have as a beginner - even having levels or stages that you can tick off as you complete them, with a detailed walkthrough for each stage. Even separating them into different lines for Timber, Aluminium, Plastics etc.

I’m sure most of the info or tutorials are already out and about, but having a structured learning curve would be great, as the SO3 is now not just for the geeky nerdy types (not having a shot here, I put myself in this category) but many woodworkers now use the Shapeoko without any prior CNC knowledge.

@wmoy and @WillAdams have both put so much work into making tutorials both on youtube and on the forums, It’d be great to see them aligned in a logical order, as part of a ‘starters pack’ for the complete newbie

Anyone try Titan’s Academy? Not really meant for CNC routers, let alone “desktop” versions but could be insightful. I’ve been meaning to start the Building Blocks course once my weekends free up.

As Vince said I think Carbide3d is already putting a very significant effort (for a small company) into creating great learning material. I also have a feeling that creating a full course on CNCing things with the Shapeoko could scare away potential buyers, as their message is around providing an affordable and easy enough to use machine, for people who need it as a tool to support whatever small business they have, not necessarily as an end/hobby/means to learn about CNC.

Anyways, this learning roadmap thing could be a community initiative instead. @edwardrford, how about releasing that ebook that was in the works one or two years ago, and let the community incrementally improve it, open source style ?

Absolutely agree on you comments re Carbide3D, they are putting in massive amounts of work and I genuinely love their attitude towards the machine and the community.

I just note the high number of people trying to work the machine out and getting frustrated doing it, and in time think it would be invaluable to have something structured to ‘show them the way’

Yeah, I’ve watched some of their videos. Some helpful, others not so much. But I still appreciate that he’s offering up the info.

Though I have to admit, sometimes Titan is difficult to watch. He just comes across really awkward at times.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.