I purchased a XL. Lots of info on here, but nowhere have I fould a simple set of instructions to design my own.

Got thru the CAD, did the ToolPaths, Loaded file. Machine dove into the hold down instantly. Stock is way bigger then completed sign will be. Any suggestions~? JohnA

Have you tried one of the tutorials?

If you’re still stuck, post your file and we’ll do our best to walk through it with you — either here, or to support@carbide3d.com

Yes, also CNC Router Essentials Book, the Shapeco CNC A to Z Article. I think experienced users are so familiar with software they don’t see what new users are missing.

did you set the zero point correct?

(and is the setting for the design’s zero point in CC the same spot in as you put the zero)

Were you successful doing one of the tutorial projects?

If not, what difficulty did you have?

Please post the file you are having trouble w/ here or send it in to support@carbide3d.com

This is a known issue … let’s not make the guy feel like he’s missing something. @johnny.Grace, you’re not alone.

Carbide is turning this around and spending extra money developing online tutorials. @KevBarn14 Kevin Barnett is tasked with this. He has two good ones now - basic tutorials that address the beginner. I’ll try to find a link to those or someone will be able to provide them.

For now…ask a lot of questions and learn by trial and error (which most of us had to do). Don’t get frustrated…just experiment. I know that’s not the kind of education you’re looking for, but it will eventually get you going. The product is really good.

I’ll help if I can…feel free to ask anything you want to know.

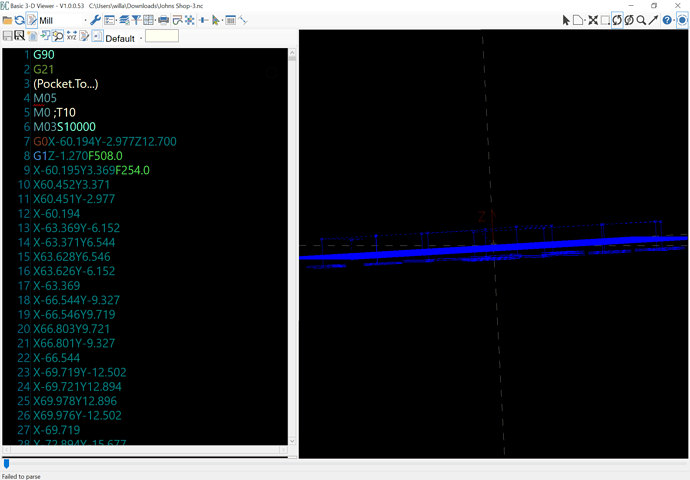

Johns Shop-3.nc (122.4 KB)

I am a long time woodworker, looking to get out of remodeling and start a custom sign shop+

There is a nice online tool called “ncviewer” that lets you check your gcode/nc files.

First thing I noticed is that you put the workpiece zero at the center of the work.

(more common is lower left; there’s nothing wrong with center).

When you set the zero in carbide motion, did you also set it to the center of your piece of wood?

THe other thing I’m noticing that your retract height is set very high (this is a setting in carbide motion’s “sprocket menu”) which can cause issues with your Z axis hitting it’s highest point… typical ranges are 0.04" to 0.08" for this.

Oh and third thing I’m noticing is that you did not (yet) set up the right post processor in Carbide Create; it’s in the settings menu.

It would be easier to sort this out if you posted the .c2d file.

As noted, origin is at the center.

You seem to have a surfacing toolpath, and then it’s making quite deep cuts as a single pass — what feeds and speeds did you use? How were they selected?

G1Z-8.890F203.2

That would be why it was plunging.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.