Hoping to get the air line through the drag chain for a super clean setup. Question is whether I can get away with 1/8" ID air line to easily feed through the chain. Any idea if 1/8" ID hose will give me enough volume for air blast or will I have to fight 1/4 ID hose into the drag chain?

So many variables…

I’d say it is quite possible that 1/8" line will be sufficient, but it will depend on pressure and nozzle orifice. The velocity that one gets from “canned air”, both the liquefied fluorocarbon type and the straight compressed nitrogen type, through a 150mm long, 0.8mmID straw can be quite sufficient, in my experience.

Avoid ID changes as much as possible in the line, in particular INCREASES in diameter, as there are where a lot of the loss occurs.

The little bit of theory I recall (and I am too lazy to go find the books that cover this in the other room, where the primary application involved is fluidizing, moving, and evacuation of granular/powdered fuel, process feedstock, ash, and so on. Yup. I have a pretty interesting engineering library at home)

Recall that it isn’t about volume, per se. The nozzle converts PV to mv^2. volumetric expansion, and adiabatic cooling. For ship removal, the mv of the moving gas is transferred to the chips, but the sweet spot is neither greatest velocity (little mass so low momentum), nor greatest mass (more momentum, but too low a velocity to evacuate chips. It is somewhere in the middle, without even considering the energy involved in hte expansion and the cooling, which can have an effect that either helps or hurts, depending.

I have been looking into this setup too. I want to mill deeper than 1/8" to make robot parts and I am thinking that even with an upcut mill, I will need to clear the cuttings. My personal mill is an x-carve that I have bolted down to a desk. Even thought it is as stiff as I can make it, it is really hard to mill bearing traces. After a nice sized grant I have acquired a Nomad for my classroom and it is already extremely accurate on 1/8" aluminum. But… If I can clear the cuttings and the heat from their production; I should be able to mill 1/4" aluminum.

How are you producing the compressed air? I saw in some of the other posts and other folks have tried aquarium air pumps. On my X-Carve the Dewalt 611 router used for a spindle produces a stream of air that will clean aluminum chips easily (maybe easier than wood chips) but the stream is not very well targeted. Just thinking but if you can direct the air well enough, it may not take a great quantity of air. Of course then you would increase your feeds and speeds and reach another plateau for clearing chips.

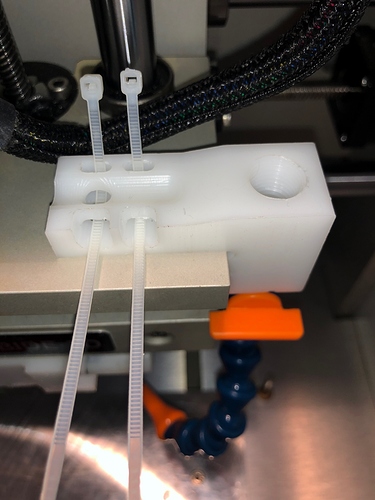

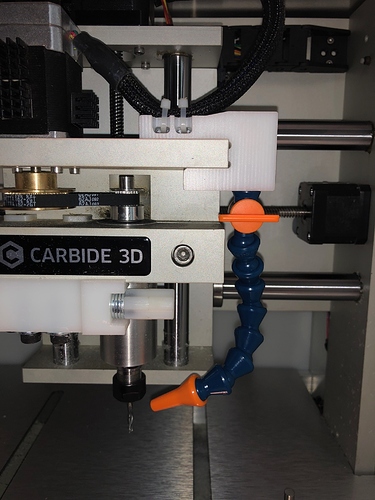

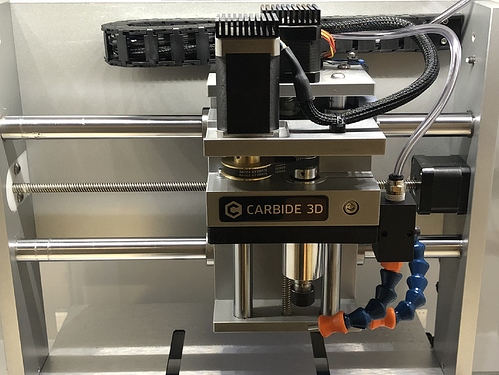

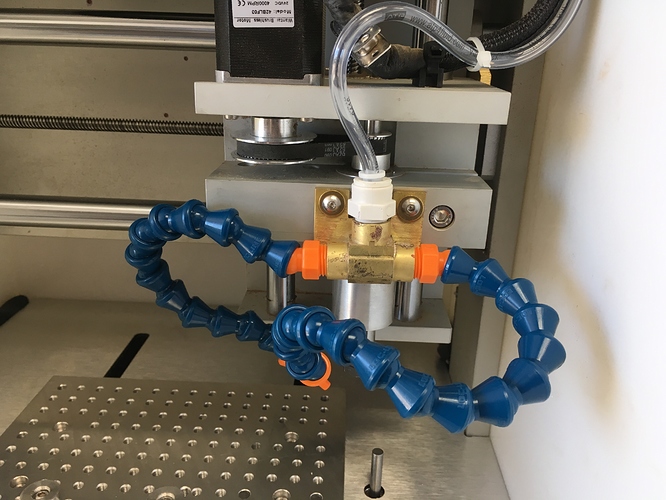

@PhilG I got 1/8" ID tubing in mine and it works well. Setup with two nozzles initially and it had no issues keeping up with chip evacuation.

@phystcher For the moment the Nomad air plan is to use my existing compressor with tank and regulator - overkill for sure, but its what I have to hand. Eventually I’d like to replace it with a smaller (quieter!) pump but I know the aquarium pumps don’t build a bunch of pressure and may not be happy with restriction and with small diameter piping that may not be the best. solution. Work in progress really.

@PaulAlfaro - very nice setup!

Yes it will provide enough air. Mine does.

Mike, how are you directing the air? I’ll bet precise focus of the air is most of the battle. I was thinking about 3d printing a little fan to mount on the spindle collet (as soon as I fix my 3d printer)…

A little fan doesn’t really work well - others have done so (I’ve got two in my toolbox…).

Mine looks like this:

@mikep Any info you can share on your pump specs?

I run a 40 gal air compressor at 20psi - but I set the needle valve I use on this very low - it’s barely a puff through the line.

1/8" line works great for my airbrush.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.