- Larger gauge number is smaller wire diameter.

You’re absolutely correct! How I messed that up…

I thought that too.

I ran solid copper wires through my vacuum hoses, connected to ground. Still got disconnects.

Then I ran a solid copper wire from my 611 to ground. No more disconnects.

The wire in the vac hose was causing clogs, annoying. I took it out. Still, no more disconnects. Some jobs I can’t use a dust shoe so I manually vac periodically. Hair stands up on my arms and head, touch the x,y,z axes with the vac hose, NO disconnects. For me, empirical proof the separate ground on the router is the answer to static-induced disconnects.

My gremlins popped up again, but not as often as before. I just added your mod and haven’t had a problem in days. Thanks!

That’s awesome! I hope this is the end of your woes as it has been the end of mine. Cut on.

I immediately started having issues once upgrading to a larger JET dust collection unit where I was losing connection to the machine controller mid program. I followed the recommendation of @HAL9000 and replaced the factory Dewalt power cord by using the instructions he provided except I used 14 gauge 3 wire SJEOOW cord and a 3 prong plug which is overkill but it’s what I had in the shop. At the same time, I stripped off some of reinforcement wire on the flexible pvc dust collection hose and grounded it to the dust collector frame. Ever since these two changes, I’ve not had any issues with the connection dropping off.

3xxl, Ran the machine with no vacuum system for months, no disconnects. Hooked up a shopvac through flexible hose to sweepy1. Suction Noise was horrendous. Disconnect after 20 mins.

Disconnected vacuum system, ran 2 hrs no issue.

Now I installed a Sweepy2, PVC and short flex hose. I am working on grounding machine.

I ran braided copper ground wire tied it to Control board cover screw, through cable train up to Z-frame, through cable train over to Z assm. Question

How would I ground the Carbide spindle/router? If outter shell is grounded to Z asm, wouldn’t that work?

.

I replaced the cord on my Makita router for my SO3XXL so I could have a ground conductor which I ran out of the casing & attached to the router body via one of the casing bolts - also to put a longer cord on it.

The C3D router has a grounded cable which grounds the router housing I believe.

The Carbide Compact Router is double-insulated and this should not be defeated.

You can ground the metal housing — the usual way to do that is to connect it to the hose (I wrap a bit of metal tape around my dust shoe) and use a conductive hose connected to a vacuum designed for such a hose and which will ground that — if the vacuum doesn’t ground the hose, then connect the hose to ground at that end.

Update: I grounded everything to the machine frame, then grounded the frame to the outlet.Ran 3 jobs in a row, almost an hour each, with NO disconnects.

What I found> The Y rails both conduct to the black frame, but the X frame and Z assm are both isolated,

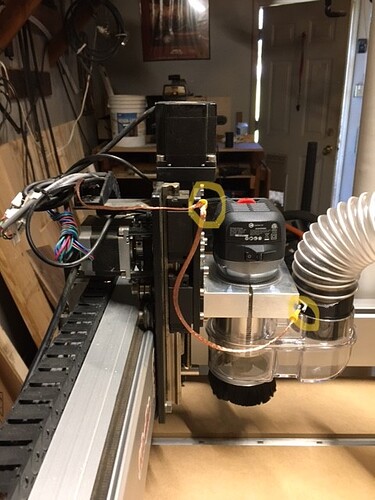

I ran braided copper from the Y frame wire train bracket screw, through train up to the X frame(black) Then through X Train to carriage assm(blk) Then to the Vac Hose. Grounded the frame. Meter now reads 0.006 ohms at highest point (Spindle frame)

That looks like tomorrows project. Thank you !

C3d router is only 2 wire, but the body mounting conducts to the Z asm, so I grounded the Z asm, which also grounds the router body.

Yes, I realized that a few days after I wrote that response. I also have a ground wire that is connected to the router mount. Keeps my router, sweepy & vac hose all grounded quite well.

- I use my old Inventable dust hose, since they provided a grounding clamp for that hose I assume the whole hose would be antistatic, otherwise grounding it would not make sense, IMO, am I right?

here they describe the hose as “…Grounded hose with a universal fitting for shop vacuums …”.

(btw: the hose pole is brilliant…)

I think grounding the hose is important. Can’t prove it, but imaging the high speed rubbing of wood chips being moved through the hose MUST cause static charge. Therefore an antistatic hose is really at least useful. I do not know how to find antistatic hoses though.

However at the beginning I had my device grounded, I thought. And had disconnection problems, sometimes in the middle of a project. And then I decided to re-do the grounding since I had to re-wire my machine with new end switches, new spindle, new controller. Now consequently every moving part separately, the hose, the controller case to one point and to a grounding plug with 1MOhm resistor. And with my reconnection project I found that one of the earlier connections just was loose. So at least it is worth to re-tighten what you have.

-

After I experienced some really nasty breaker issues I asked my electrician to provide me with 8 separate circuits with separate power outlets. You would be surprised how fast all these are used! So like you never can have enough clamps there are never enough separate power circuits in a wood shop… If you have and use separate phases if they are used there is no way to get the same issues even through the brakers on the same phase, so it is useful to know what outlets belong to the same phase. The grounding wires should not be too thin. Good orientation would be the diameter of the green wire of the power tools you use.

-

yes, the coating should be sanded off at the place where you connect the wires. Spring washers with sharp edges help to safely connect aluminum since this always withing few seconds exposure to air already builds an insulating oxide layer.

Thanks for the inspiration !

As you noted the X axis was running 10 ohms or so and the Z axis had zero continuity.

I grounded my SO pro 5 components. 1 ohm max across the machine including the wire in the vacuum hose.

I’m getting the Shapeoko 4 for Christmas, and I’m trying to set everything else up beforehand. I’m planning on using my Dewalt Stealthsonic vac with a separator in between. I thought about getting a Dust Right® 2-1/2’’ Anti-Static Dust Hose from Rockler to address the static problem. Anyone else have luck using this hose or have other recommendations for anti-static hoses?

As long as the hose is grounded in some way, it should work. I’ve never used an anti-static hose myself - just wrapped some grounded bare copper conductor around my shopvac hose within the first 12-16" of my dust boot when I first started.

Now that my machine has a ground conductor directly attached to the spindle mount, I’ve never had any issues with my vac hose picking up much of a charge - seems to leak enough charge thru the Sweepy boot clamped to the router to keep charge build-up low.

So I would think that most any anti-static hose would be foolproof, provided it is grounded.

The anti-static hoses seem to be a big win, and all the stuff I’ve bought from Rockler has been great. (I bought an anti-static hose from Fulton/Peachtree back when they were available.)