has anybody used a small tapered bullnose for making a inlay? is it still just set up for v bits? anybody know the setup numbers or how to figure them??

The geometry of a tapered ball-nose does not work.

If you lie to the software and enter a more acute angle which results in the same tool length you will get steeper sides, but points where a sharp internal corner would be realized by the sharp tip will be rounded by the radius and show distortion from the actual geometry of the tool not matching the ideal geometry used to calculate the tool movement.

Caveat up front: Find a software that supports your tool ![]()

I’m also going to assume you meant tapered ball nose, not bullnose…

It can be done, but it would require a bunch of math & lying to the machine/software.

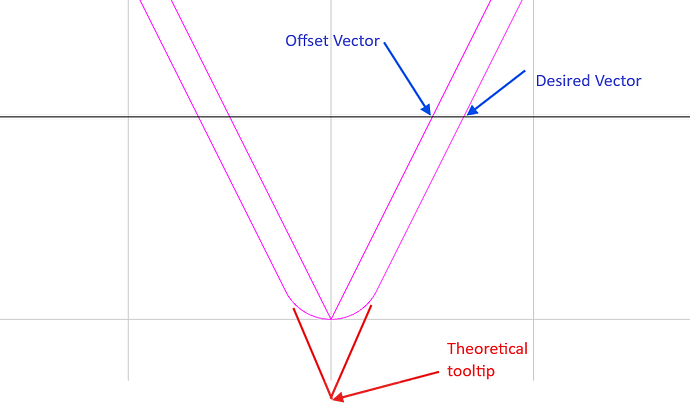

Since V-carve calculates based on the sharp point of a V-bit, you would have to calculate offsets at the depth you are carving to get the tool to carve the desired results. You would also have to calculate the length from the tooltip, center of ball, to the theoretical point that the program outputs to set your Z zero.

You also need to make sure there are no vectors with radii / curvature less than the radius of the ball on the tool.

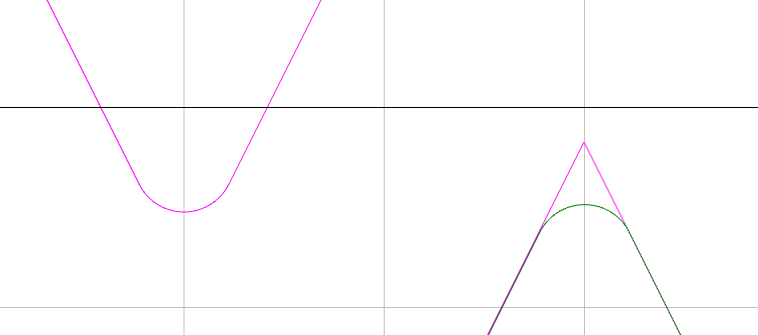

Narrow areas that have the Z adjusted to pick out a corner will leave a radiused corner on the female side. On the male side it will result in a sharp corner. These corners will need to be rounded off to match, or greater than the ball radius to make them fit.

If you really want to dive down that rabbit hole, post the project or example, along with the tool details & the depths you’re shooting for and we can show you how.

The only one I have run across is F-Engrave.

EDIT: I took this image I put together in Inkscape:

And carved this with it, back in 2016 or 2017, just to try it out.

It went well, and then I did other things with my SO3 until Vectric V-Carve caught my eye, and I have been using that ever since. So, I do not have a pic of a “B-Carve” as it is called, but F-Engrave is capable of it.