Been searching a lot, looking at threads, seeing a lot of non-related things discussed - just looking for people who are using festool extractors & what their setup is, thanks for any help! What adapter is being used what size hoses are you using, how are you booming it over the machine etc. I have a 4 pro XL. Thank you again for any help from people using festool with sweepy 2.0.

Have you checked Rockler? They have a variety of adapters and also sell Festool.

I have looked over there a little bit. I am hoping for what others are doing already & proven to work, it is doing my head in trying to figure it out! I do have a 4 inch dust collector, and an anti-static 2.5 inch tube, but it has not ever been setup because apparently that is not good for the air flow and possibly bad for the dust collector, too. It is driving me nuts. Maybe I am overthinking it, so that is why I need to just see what someone else is already doing & do that. I do not need perfect dust collection, just capture all the fines and most of the smalls I am good with cleaning up some stray stuff after. Just getting it actually setup and knowing exactly what I need is the hard part. It is making me frustrated so it is best to ask for help & working examples from other festool CT users. I really do not want to use the 4 inch dust collector for this. I want to sell it tbh.

Edit: I do have a festool to 2.25 inch adapter for inner diameter of the table saw coming from an Etsy seller, too. Maybe that will fit the inner diameter of the sweepy or its extra adapter part, so it’ll be a possibility to look into. Still, would love to see what others are doing & setup similar for myself. Especially booming/suspending the hoses. I may just buy the festool boom stand soon, too. It’ll be handy in more applications than this, at least.

First, the included adapter should fit the tapered Festool hose — that said, my recommendation is to use a 2.5" straight hose (ideally getting one which is conductive/static disippative).

A cyclone will help a lot in terms of saving on filters and bags — I got an Oneida Ultimate Dust Deputy, but we now sell:

Then you will need:

- 45 degree plastic angle/adapter to the cyclone (one was included w/ my Oneida unit)

- 2.5" hose clamp

- 2.5" hose

- 2.5" adapter (included with the Sweepy)

- 2.5" hose clamp

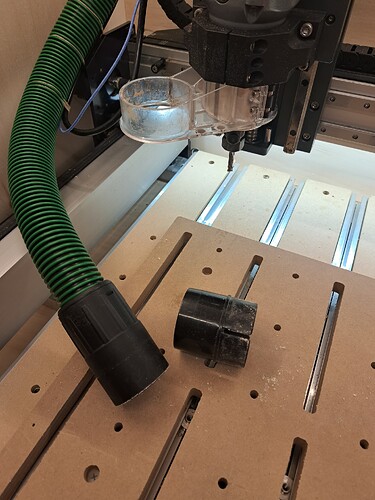

My current solution is not elegant but works. I found various bits to creat this Frankenstein at Lowe’s. I am planning to replace the 2.5 hose coming down from my big collector with a 4” and put a 4” blast gate higher.

I have thought that I don’t get as much airflow as I should with the current setup and sometimes open another gate elsewhere assuming I may be starving the dust collector of flow.

I use 36mm hose directly into the sweepy.

Just had to replace the ‘tool end’ of the vacuum hose with a ‘vacuum end’. Dont have the festool part number with me.

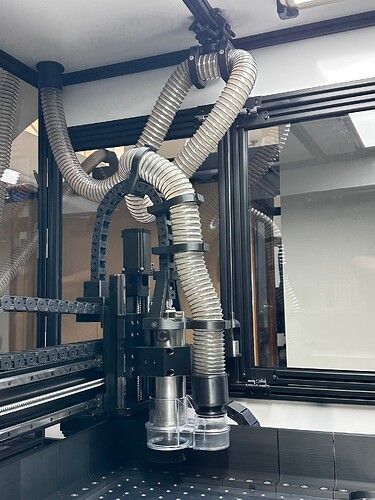

Using elastic bands to route the power cord to a hanger on the ceiling of my enclosure.

I should have mentioned, I also have Festool’s cyclone mounted on top of the CT26. Nice that Carbide now offers that Mullet unit! It is a good looking unit. When you say the tapered hose should fit the adapter (I do not have it in front of me right now), do you mean the standard 27mm end hose, or the 36mm? I intend to get a 36mm soon anyhow, so either will work. I do have the 2.5 inch 20 foot power tech hose, so I may also try something like that, similar to what @CullenS has going on. I also like very much what @spcnc has done - maybe I will go with that style hose when I go for the 36mm instead of the tapered one. I think that one might come with one of the cleaning kits as well, which would be handy & more cost effective to get the hose that way, too.

Thank you so much to everyone sharing their setups. Looking forward to any more that may show up and have a good starting point + great examples, really taking the stress out of it, feeling like I am no longer going-it-alone!

You can buy another "vacuum end’ for your 27mm hose as well and just use that but with less air flow then the 36. If buying a festool hose I recommend buying with the cleaning kit as it is less $ as a whole package.

Side note: read the festool description at different sellers, the store I bought from mistakenly said a systainer was included in the price when it shouldelnt have. The store was nice enough to honor the price and give me the systainer but they sure quickly fixed the ad!

I use the standard 27mm. I have a CT-MIDI with a CT-CYCLONE and it fits without issue. I have a piece of unistrut that spans my work room. I have trolley that freely rolls the Y axis and being Festool hoses have built in swivels… it just runs along and does its thing. I use a simple bungee to hold it suspended from the trolley.

This looks like the way to get me up and running with dust collection quickly & efficiently. I checked the adapter now, the one @WillAdams mentioned & that you are using on your setup & it does look like it is going to work! I am stoked about that. I am still going to try to figure out a way to incorporate the 2.5 inch solution, however, this will work & maybe it will work well enough to stick with it! How do you feel it performs?

My experience with the Festool hose was that anything beyond light cutting, minimal chips, it would clog. Very annoying to de-clog.

My $.02, your mileage may vary…

It can get bogged down with heavy passes with the grain that will create long splinters….

That being said… I’ve ran 1/4” bit at 125 IPM, 1/8” DOC and filled my CYCLONE 50% in a single afternoon. I am probably going to get a 2.5” hose and a 4” to 2.5” reducer for my larger dust extractor and run it along the strut for the same concept and also for the noise reduction… though… the loudest thing in the room tends to be the ballscrews, tbh. I still LOVE this machine. Quirks and all growing pains included.

Problems w/ the tapered Festool hose:

- noisy

- more likely to clog — this was both worse and better on Sweepy v1 which actually tapered down to it — better in that the clog on that was at the Sweepy, worse that it happened more often

I still have the Festool hose hanging rolled up on my CT Midi, w/ a brush attachment on it, and use it for vacuuming (w/ hearing protection) away from the machine, but at the machine, I actually found it worthwhile to cobble together a brush attachment setup which would work w/ the 2.5" hose.

Here’s what it will do with a 27mm hose on high with the Cyclone. There was zero additional cleanup performed prior to that being a flat piece of material.

*Also… keep in mind I am using a VFD… if that was a palm router blowing the dust down… probably not as efficient.

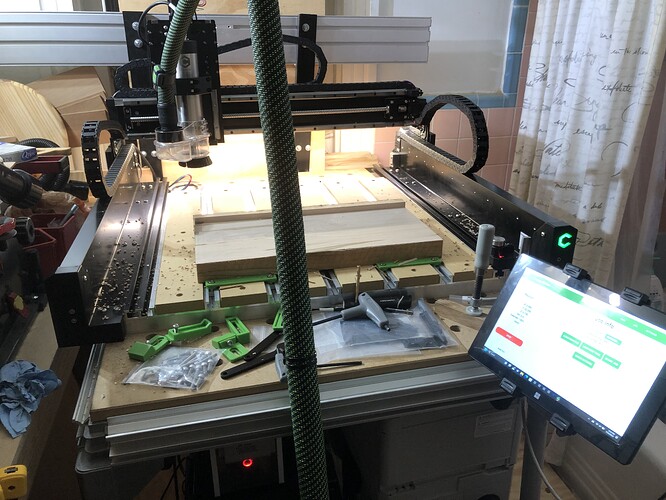

I use the standard Festool hose with Sweepy. Also a Festool dust collector with an Oneida Dust Deputy. Overhead support for hose is one of the first things I made with the Shapeoko. Dust collector is on a separate electrical circuit from the Shapeoko. No problems with static.

I designed and print my own Sweepy v1/v2 adapters and a cable chain adapters for the water cooling hoses and power to the spindle with other related parts, including bulkhead adapters and hose trolley with pulley and counterweight systems to fit a 2.5" Peachtree hose. I would suggest you run a grounded Peachtree hose out of the machine and then convert it to your Festool hose size.

My Peachtree hose adapters also fit the new Dewalt and standard Dust Deputy extractors.

I can make any hose size adapter you need but I would need you to ship me the hose end to make it fit perfect.

Based on @WillAdams professional recommendation… I hit the Woodcraft. Already have a 2HP HF Dust Collector with the Wynn canister + Jet Cyclone and Rockler quick connects. $55 and out the door with 2.5” hose and a reducer. Dust collector is plugged into a Apple Home capable outlet so I just switch it on with the phone.

I use the festool vacuum as a vacuum source- I then use a 5 gallon plastic Buckert ( harbor freight ) with a round plywood lid ( cut with my cnc machine) - The disk has a grove cut to allow the rim of the bucket to fit into the groove. I then use some slim weather proofing gasket in the groove to fit the bucket edge into. This forms a good seal. I then purchase a small cyclone ( plastic ) form amazon of other source. I then hook the festool vac to the cyclone and un a tube to the sweepy. The vacuum pulls the dust into the cyclone, and the cyclone removes 90+% of the chips and dust an deposits them in the bucket. The remaining air then is exhausted though the festool vacuum. This allows me to far extend any filter cleaning of the festool and easy emptying of the bucket. To manage the hose fixed to the cnc “sweepy” i have mounted with a single screw a piece of ply 2" wide 24" long that the hose is attached to the sweepy. allows adequate length to allow your machines max movement both ways. The device figment when made allows the hose to swing right to left in an arc, keeping the hose form dragging due to the pivot point of the screw. Also using zip ties, you can affix the power cord to the vacuum hose going to the sweepy. works well, keeping the hose in a proper position as well as controlling the tangle of the power cord. if you want a pic send me your email Tom

Please post the photo here (or in a new thread). This would be worthy of its own thread.

Just a bit of experience with using Festool Vacs with a cyclone… still change the bag after every 5 or so dumps… the fine dust will clog the bag to the point of CFM loss… I think this is why there is so much hate on the CT-Cyclone (besides cost). YMMV