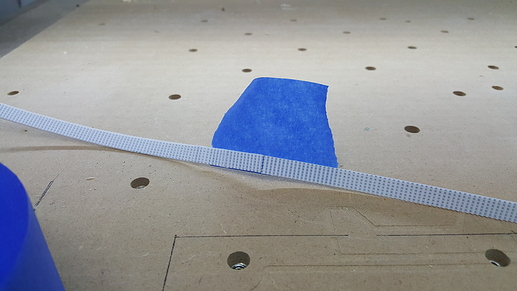

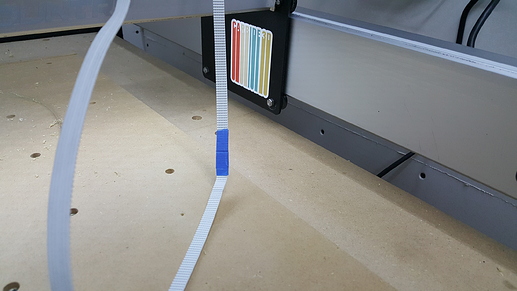

Little tip for easy belt replacement when the time comes: undo one end clamp and loop the new belt through and reinstall the clamp. Take the end of the old belt and secure it to the end of the new belt with some painters tape like so:

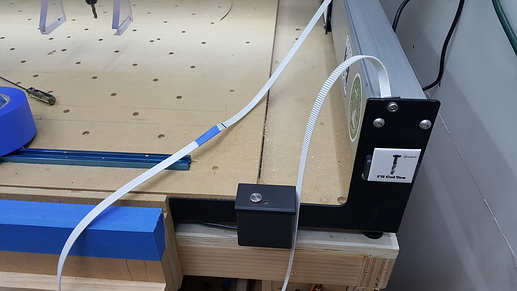

Now it is easy to gently pull the new belt through the pulleys and such with the old belt. No fiddling around trying to coax the new belt around all of them. Maybe some of you do this already, but I thought it wouldn’t hurt to share it with anyone new to the community. I can swap a belt now in just a minute or two without having to pull my machine out of its “room.”