I wish you were my UPS account manager…

Ups has that 40% off code, we use that all the time. Saves until we find the need for daily pickup which costs money… ppl don’t realize that.

What’s the 40% off code, and when does it end?

“EASY” ends 12/31/2019

40% off air 20% off ground

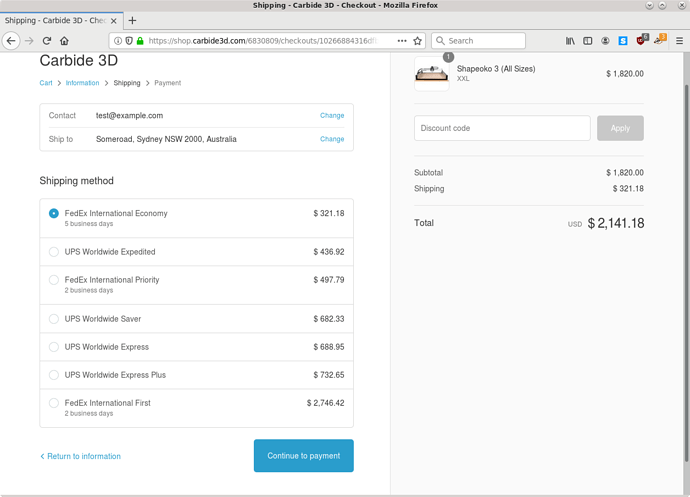

Wonder if deserves special mention in a Carbide 3D Blog post or similar? For international buyers, the shipping charge is a considerable factor.

So this is only available if you haven’t already negotiated a shipping rate for your company. If a company has the demand (min package per day) the carrier will negotiate a better rate. I’m sure CB3D already has this in place. More of an option for smaller companies/individuals who don’t have the demand for lower rates.

Although yes some things could be cheaper to ship. Say the $20 I paid to get the probe shipped to me, could have been $7 usps flat rate small. And guaranteed in 2 days+ internal processing time.

I also received a replacement part once. They shipped it fedex 2 day, I’m sure the usps 2 day flat rate small would have been much cheaper for a pulley wheel, and fed ex failed to deliver on time.

But I say this, being a relatively small company handling multiple carriers may just not be logistical on their end at this point. Hopefully in the future.

I know they just included the shipping cost with the machine now, which should hopefully help those across the pond with the shipping costs… hopefully.

Yeah, that wouldn’t exactly be logistical for any company. Say when I ordered my machine shipping took like 3 days cost me just under $83 for shipping to Southern California from Illinois where they are shipped from… So now that shipping is included in the price, the machine costs more. So the company paying an extra $240+ for international shipping to a customer outside of the US wouldn’t make sense… Maybe deducting the $80 from the $321 international shipping by calling in would be possible? I dunno. I don’t work there. But they are a great company. And shipping is never really FREE… Its just a way companies market goods. Say you get free shipping on something online but find it cheaper in the store. So was shipping really free?

Etsy is now offering free advertising if you offer free shipping to US. Now one wouldn’t keep their prices the same as they currently are and then start paying $20+ out of pocket for shipping, they would increase prices accordingly and advertise the free shipping.

Will this setup work my beaver pro?

2x 60volt 10amp 600watt swishing power supply

Lead Shine DM860H Stepper Driver

Stepperline 23HS45-4204S High Torque Nema 23 CNC Stepper

Spark Concepts CNC 4 Pro Controler

Setup to run external drivers, and powered by separate power supply.

It depends on your controller and your steppers.

Thanks. Updated post with full config

I’m interested in the Z axis upgrade, but would like to know more about it. Are there any plans to put up some info on the web somewhere? And, since I’m Canadian, I’m interested in shipping to Canada. Are there any plans to offer the upgrade through the Robot Shop Canada, which is where I bought my shapeoko 3?

Yep, or you can use the same motor setup for the HDZero.

We should be updating the listing shortly with photos. Is there anything in particular you would like to know? If you do a search for HDZ you should see plenty online.

We can ship to Canada when back in stock, at this stage there isn’t any plans sell the HDZ through other distributors.

Luke

Thanks for your reply.

I’m looking at the beaver upgrade for a couple of reasons.

First, I’m working in plastics a lot and getting melting problems with my Dewalt611. I have a feeling 16K RPM may be simply too fast to get really good and consistent results. In addition, I hope in future to mill aluminum and copper, so I need a goodly amount of torque. This all makes me think of a 2.2 kw water cooled spindle which requires an 80 mm mount and weighs some five pounds.

Second, I have some (admittedly slight) problem with tramming and haven’t been able to resolve it by fussing about with my Y-axis rails. This makes an easy-to-tram Z axis plate interesting. I’d like to know more about this feature.

I’d also like to see step by step conversion instructions. I read somewhere (earlier) that someone had problems with screw holes that were not precisely aligned. I’m assuming any such problem has been taken care of, but I’d like to be certain.

I’d also like to know a bit more about the mount. As you doubtless know, the Dewalt 611 takes a 60 mm mount which comes with the Shapeoko. Do you plan some sort of adapter so I could start out with the Dewalt and later shift to the spindle? Might be a bit easier on the budgeting if I didn’t have to handle both at once.

And, of course, when do you contemplate having stock?

I was in a similar situation, in the “16K is too much” sense and went a similar route. I ended up going with a 1.5KW air-cooled spindle, the HDZ and the spiffy no-touch limit switches. My spindle is the same diameter as the Makita router, so I am using it with the provided ring.

I mention this because you were asking about the mount - I’m using the stock mount right now; it goes on the HDZ without an issue. So you can definitely do things in stages.

I had no issues at all with the installation; no misaligned holes, no missing parts, linear rails were nicely aligned out of the box, the whole thing. I’ve been extremely happy with the whole thing. And yes, the easy-tram plate is very nice indeed. Shim to get the rotation around X sorted, then the eccentric nuts to get rotation around Y - very simple and friendly.

I don’t mean to dissuade you by any means from getting the HDZ or a spindle, I just want to make it so you might be able to have better solutions in the future to problems you are seeing now, whether you stay with what you have or with the HDZ.

Plastics melting -> You should get a single flute endmill. I run acrylic and polycarbonate at 20,000 RPM with a single flute at fast feedrates (1500 mm/min) with no melting. It makes a world of difference in plastics.

Aluminum and copper -> Totally doable on a Dewalt DWP611, I have the same router and mill aluminum often. Not that much torque needed but definitely more is appreciated.

Rick

Thanks much. Gives me a bit more confidence. Not necessarily enough to take the plunge, but a bit

Jonathan

Thanks much. I did try a single flute earlier without a great deal of success, but perhaps I had the wrong feeds and speeds. I’ll try your settings and see what happens…

@RickT - what air cooled router did you get? Would you recommend it?