Hey folks, thanks for being patient as I get this done.

I did not pursue the cyclic testing for now as I was not sure whether the failures in the field were due to tensile loadings or from stress of rotating around the pulley. If it’s the former, I can test it simply, if it’s the latter, I don’t have a good way to test that.

I did run the tensile loading measurements and wanted to recap what @AlexN found.

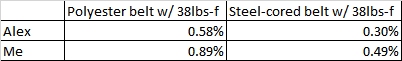

Alex’s measurements were:

9mm stock polyester belt w/ 38lbs-f = 0.58% strain

9mm steel-cored belt w/ 38lbs-f = 0.30% strain

Equipment

I used an MTS Sintech universal testing machine (http://www.mts.com/en/products/producttype/test-systems/load-frames-uniaxial/universal/electromechanical/index.htm)

Procedure

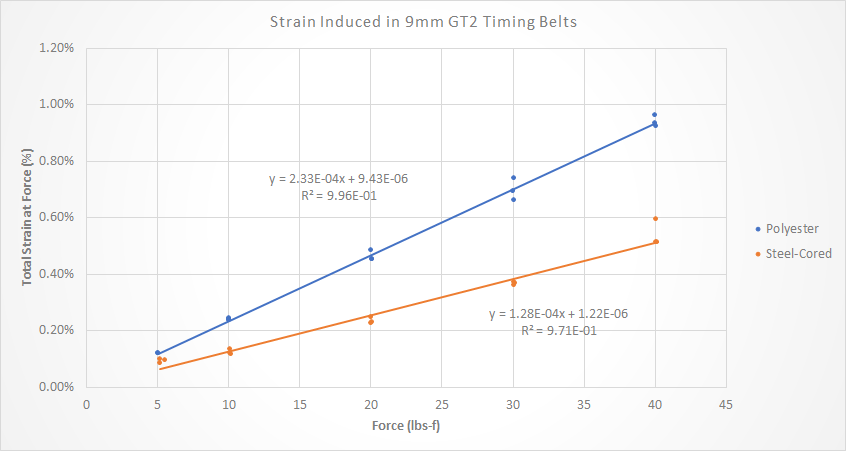

I loaded the belt into the grips of the machine, ensuring 150mm of distance between the grips. I then loaded the belts with varying amounts of force from 5-40lbs (at 50lbs-f the belts started slipping from the grips).

Results

My results show higher strain values than what Alex measured.

For comparison:

The full data is below. So while my values are higher than Alex’s, the trends are the same. He measures the steel-cored belts at 52% stiffer while I measured 55% stiffer. We can chalk that up to experimental error.