THAT is really clever! My SO5P is 4’x4’, but for smaller projects, that looks super convenient! Well done.

I actually really like these, thank you. I may order some despite my other posts, for projects with higher demands.

I use a glue gun. Works well.

Seems like this would make tramming important in only the spots where your pods are. Although I guess you move them around as the job demands. I like this idea as you can put the pods inside the boundary of profile cuts and not have to worry about cutting into a larger vacuum table.

I don’t have a 3D printer but have a buddy with one. Care to share your design or are you planning to market it?

I have a vacuum pump that I inherited from my brother. He used it on his lathe to turn the bottom of bowls without having to clamp the top. I haven’t used it yet but assume it would work good in this situation.

Here is a screen pic of my most recent pod I create on Fusion 360. I don’t use outer tabs for screws/bolts and I’ve decreased the diameter. I drill a center hole (.25") later for the T-bolts. For sure I’ll post here my Fusion 360 file that’s ready to be Sliced in the slicer of your choice. Let me leave you here some features of it so you’ll know it it’s something you want.

After couple prototypes this one is my go to. It’s 3" outer diameter, .8" height. The seal channel takes any common 1/4" x 1/4" foam seal. I use inexpensive material off Amazon that has a peel back on one side; weather seal? The holes are a tapered fit. Tape the holes inside or out as needed. Link the pods in a chain if you want. I use 1/4" tubing. I guess you can use most any 1/4" flexible tubing. I use polyethlene from home depot. I tried several different designs where threaded in some push lok fittings and then tried a couple different dimensions of a tapered hole. It’s seals perfect and detaches easy, no fittings needed.

I move them around to secure my wood for v-carving. But I recently moved to cutting materials as well and it couldn’t be easier. 1 or 2 (or more) under my material inside of my cut path, tape down my tubing if they are rubbing my stock and make the cut.

VacuumPod.stl (93.8 KB)

The .stl file here is straight off Fusion 360. I don’t know why the emblem/icon is a V-Carve image. I don’t use or have V-Carve but they get saved with that image, hum. Anyway, the file goes right to Slicer software from Prusa for me with no problems. I’m sure it will slice on any common 3d printer slicer software. I’ve printed it with PLA and PETG, it won’t matter. I also don’t select “support” in the holes. You’re friend with a 3d printer will know about support material.

Vacuum pumps designed to work with AC systems will produce oil/smoke. Been there, don’t want to work around those pumps any longer. The pump I use is a diaphragm type off Amazon. Quiet, plenty of volume and ultimate vacuum for my table, and no smoke. Happy to post notes on vacuum pumps if anyone wants the conversation.

Metalbender

Maybe I could just machine them out of PVC and drill the holes?

I will take a look at the pump I have and see what its specs are.

I made a 24x29 inch grid out of pvc that continues to work great. I also bought the Amazon vacuum pump and you cannot tear a sheet of acrylic off of it… and some MDF pods for small stuff. (you need to seal the MDF except where you want the vacuum) I also have the commercial pods from Rockler, but making the pods is super easy with a few things from Amazon. I know you are in Savannah…if you’re ever near Charleston stop in and see how it works!

Do you have a link for that?

I’ve also designed some 3d printed pods.

Sounds great. I am about 2 hours away. We get up there occasionally. We like to camp at James Island.

If you ever come this way let me know.

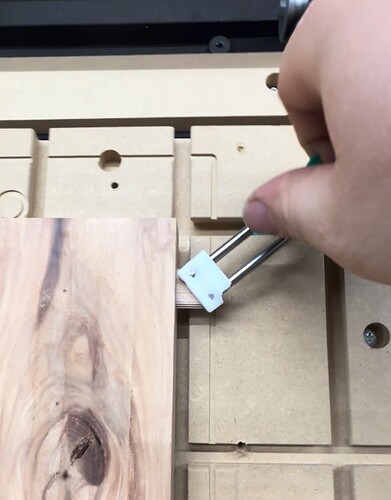

Something that’s worked well for me is a combination of the oops clamps and the Micrjig matchfit system. The standard bolts will reach about 2 inches so you would either need longer hardware to reach the full 3 inches, or something else I’ve done is sink a domino in the side of the workpiece and then clamp to that. Hopefully the photos help you see what I mean.

I fired up that pump I mentioned. I wasn’t impressed with the power but I don’t really know what to expect.

I guess this is one of the ones you don’t recommend.

It could be worn. Or the finger test that we all do is not a good representation. When it pulls over a large area. That force is distributed over that area.

Maybe, probably, might be.

Good luck with it.

I don’t see most using a reservoir tank for vacuum. That way your fixture always sees a more constant vacuum. Its also a good way to test a pump’s capability and allows a less capable pump to work better.

PS. I’ve used an old obsolete 20 lb. propane tank.

That Gast pump ( and that PN# in particular) has plenty of Hg, might lack the cfm to power more then 1 tightly sealed vac pod, might be plenty. It’s a diaphragm pump and won’t product oil smoke, that’s good. Gast pumps last many many hours in lab use. I doubt a woodworker could wear one out.

This is the lasted pump I got off Amazon. It’s got about 1.7 cfm and capable of pulling 27 in/hg. For me it’s very quiet, has a regulator/filter inlet and a gauge. Forget the increments on the gauge. They are in cmHg and MPa. That make sense to lab people. When reference the gauge I look for a needle position that has historically held my materials in place.

https://www.amazon.com/gp/product/B07WS97JWQ/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Something we could start a whole other post category on and that’s vacuum fixturing. Lab’s and other industries use vacuum more often then not on “sealed” systems and enclosures. As woodworkers we have to manage or control leakage. It’s no big deal but that’s what we have to work with. A .5 cfm Gast pump capable of 28" of Hg could pull down a 4’x8’ sheet of plywood on a big CNC if you could eliminate leakage.

On our smaller more manageable spoil boards just make sure your surfaces are smooth enough so when you contact your foam and rubber (what ever you are using) seals that you can see a steady vacuum of 8-10" Hg (or more if your system is tight). Rough sawed lumber doesn’t like sealing. Need to plane it or sand it. Most plywood seals fast and tight, MDF not so much. I made a spoil board once out of Lite MDF 18"x34" and hooked 2 Kirby vacuum cleaners (vacs were in series) to it. Held a 6x6 piece of wood in the center and V-carved no problem. It was rather loud but both ran on 14 amps total. Not a bad efficiency.

I bought the ones mentioned above and I got tire of messing with the allen wrenches. I wanted to just tie something down without tools. You can see what I did in an article that I wrote about that. Here is a link to what I wrote: HERE

Here is a picture of how it worked out.

I’ve made the holddowns out of Walnut, Ash, and Oak. I would think any hardwood would work.

Douglas

Martin, as you know, different methods are needed, depending on the workpiece/spoilboard. Thanks to Mark Lindsay CNC (https://www.youtube.com/watch?v=3uTsQ3dYRrk) your dilemma is solved (I won’t be going back to some of the antiquated hold-downs. Like you, I don’t like double-sided tape (gums up bits badly), but when you use cyanoacrylate between two layers of painters tape, you workpiece won’t budge a hair. Be sure to watch his YouTube on the subj (link above). No need to buy the costly Green Frog tape (pretty difficult to remove); inexpensive BLUE painter’s tape works best in my opinion. …Don Johnson, retired cabinetmaker in Oakland, CA

Don, thank you so much! I think this will be ideal for my application!

This topic was automatically closed after 30 days. New replies are no longer allowed.