First of all, you have a CNC and a 3D Printer, and you’re obviously skilled in SolidWorks. Why would you buy an enclosure? Get a few sheets of acrylic and design your own! Makes for a nice project too =) I bought an acrylic one about a year ago and I’m really happy with it, but now that I have a CNC, I likely wouldn’t buy another.

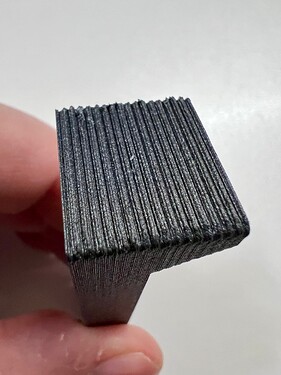

Anyway, the print came out gorgeously. Prusament PC-CF prints like PLA, albeit at a high temp. There is risk of warpage on larger parts, but for parts this size, it’s unlikely. I did use a draft shield, just in case though.

Here it is hot off the build plate. No warping at all. You can see the organic supports I used to support the inner ledge and, apparently, some of the gator teeth.

Both supports popped off with almost no effort

Close up of your gator teeth

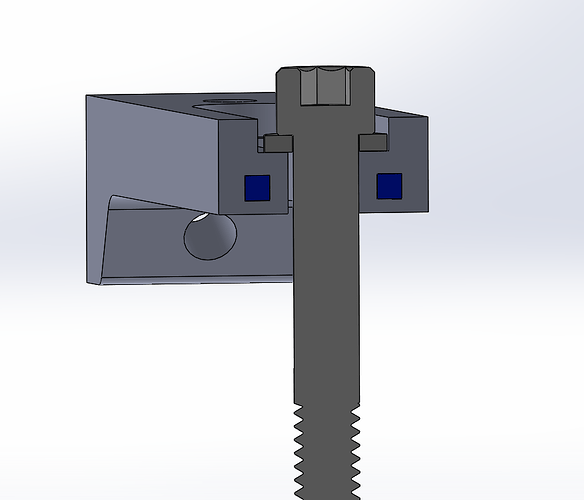

Note, this model was re-designed (and likely poorly interpreted) from your PDF drawing in your shared drive. I didn’t bother with the hole through the teeth as I didn’t see a need for it for my use, and, if I decide otherwise one day, I’ll print some new ones =)

The teeth would have come out better if I had used a smaller layer height. TBH, ideally, I would change the pitch of the teeth to be a multiple of whatever layer height (or vice-versa) I was using to get more consistency in them.

It seems really rigid. If I attempt to bend it with my hands with everything I have, it yields maybe a millimeter.

Not sure how accurate this chart is: https://help.prusa3d.com/materials, but according to it, the Prusament PC-CF has a better temperature resistance, impact resistance, and tensile strength than PLA, which is already pretty strong. Of course, it’s also much cheaper than PC-CF, but, the main reason not to use PLA for an application like this is that it slowly, and permanently deforms under force.

With the supports and the draft shield, this print required 17.95g of filament and at ~$75/kg, this comes to about $1.63 to print. Using an enclosure would let me drop the draft shield and I would save 4¢ (lol). Interesting to note that it looks like the green ones we get from Carbide3D are injection-molded PA-GF of some sort. I don’t know specifically which blend, but, by all accounts, that material probably isn’t as strong as PC-CF. The Carbide3D ones are injection molded though, which, as they say on their sales page, probably does eliminate breakage at 3D printed layer lines. All said and done, I’d say printing your model with PC-CF with 100% infill and a decent printer will probably be as good as the green ones, which, are priced about the same anyway, so, the real advantage is not cost, but being able to print one up on demand and to your exact specifications.

Anyway, Perhaps I’ll carve up some stair-stepped wood blocks to make using this useful for even taller stock, and see how it works out. I do appreciate your model and willingness to share!