I’m looking into working with resin to enhance wood work. Any suggestions for a clear resin, easy to use, that doesn’t require a vacuum chamber?

I use West System, it is expensive as it is normally for structural fiber work but I have some so instead of buying more resin, there are other that will work well for inlay work.

Total Boat makes resins they market to the woodworking community a lot and from what I’ve heard and seen should work well.

If your wanting something that will have less issues, and bubbles, use west system with a slow hardener. The 50 50 stuff creates more heat and thus more bubbles, cures quicker so less work time as well. Invest in a nice adjustable heat gun. Torches work well but require more finesse. Be sure to make the area 100% dust free as well.

You can achieve nice results from even the stuff off the shelf at Lowes or Home Depot

One thing to know about resins is that they come in two different types that have different characteristics Epoxy vs Polyurethane and you cannot mix them together. They each have their strengths and weaknesses. Polyurethane is more flexible while Epoxies are stronger but more brittle to significant impacts. In addition, generally Epoxy cost significantly more than Polyurethane.

The West System is an Epoxy based resin.

No specific recommendations (I’ve used all but currently use West System), but some general ideas:

You’d be surprised how far you can go without a vacuum chamber - careful mixing can go a long way. Depending on the specific product, some alcohol in the mix will also help thin and get the remaining bubbles moving to the top.

A heat gun will help pop the surface bubbles, too. Or just breathing through a straw…

Also, if you have a foodsaver with vacuum marinading tub, you can just degas the epoxy and not the whole workpiece for substantial effect.

I used this epoxy several years ago to do the counters on my mom’s back porch. It was my first go at using epoxy and the countertops turned out really nice.

Fast forward about 15-20 years. I get my wood from an 84yo guy that runs his on band saw mill (amazing guy). He also does a lot of epoxy work. Mostly live edge tables and clocks. Anyway, I asked him where he got his epoxy and lo and behold it was the same place I got mine so many years ago.

http://www.tomscypress.com/epoxy.html

If you like supporting the little guy, give him a chance. I had great success in the past and my wood guy makes some amazing stuff with this epoxy.

I use Total Boat for filling knots, cracks etc. but if I want something that needs to be clear and wont yellow I pay up for Art Resin, its not cheap but it beats the competition in most categories from clarity, to low VOCs, to UV resistance.

I did a recent project where I carved an area out, painted it, added a vinyl logo, then filled with clear epoxy (Art Resin) and I was very happy with the result

I’m just a stalker here. I won’t be getting my xxl until first of the year  . But I have used resin in my woodworking. Polyurethane resin is softer than epoxy but will react to moisture in wood and causes the resin to foam. You must seal the wood first or you will get a rather nasty result. Alumilite turns really nice so I suspect it will cnc just as well. Epoxy will yellow so if you are using it for clear applications take that into consideration. Both resins can be colored. I hear a lot of people use West Systems as noted. if you want some alternatives check out Smooth-on.com. They have both epoxy and Poly resins. Diamond is also another choice.

. But I have used resin in my woodworking. Polyurethane resin is softer than epoxy but will react to moisture in wood and causes the resin to foam. You must seal the wood first or you will get a rather nasty result. Alumilite turns really nice so I suspect it will cnc just as well. Epoxy will yellow so if you are using it for clear applications take that into consideration. Both resins can be colored. I hear a lot of people use West Systems as noted. if you want some alternatives check out Smooth-on.com. They have both epoxy and Poly resins. Diamond is also another choice.

forgot to include that there are epoxies formulated for clear applications. Most you can find on Amazon. I would suggest you go to the manufacturers site for application info.

Here is a link to a smooth-on video. This particular epoxy does not require a vacuum as you can see. https://www.smooth-on.com/tutorials/river-table-clear-epoxy-casting-resin-reclaimed-wood/

I use Pro Marine all the time in my woodworking. Has a longer work time and always give me a clear finish. I use different resins for different projects. Alumilite slow only give you a 12 minute work time. I only use their product if I am using pressure pot.

Don’t know anything about this, but TotalBoat just announced a new resin called MakerPoxy in collaboration with a maker that does a ton of wood/resin stuff.

It’s a preorder that doesn’t ship until November, but it might be worth looking into.

I have been working with epoxy for the last couple of months. I took a four day workshop here locally in Grand Junction, Co. They do this workshop once a month for $200 but they give you that much in product when you leave. It’s 25% off that week and 10% off after that for life. It is eco-friendly, self leveling and very clear. They also offer numerous colors for base coats and accent colors. I did 3 countertops, 2 river tables and a large outdoor bench. There is two different links to their product.

https://diamondcoatepoxy.com/

https://www.countertopepoxy.com/

Diamondcoat epoxy is exceptionally easy to work with. Mix proper ratio between 70 - 75 degrees, let the chemical reaction heat to about 90 degrees and then work… Countertop epoxy is 1:1 ratio between resin and hardener and casting resin is 2:1 ratio. Lots of videos and info available at their sites for the novice. I will post some pics.

I did some fractal wood burning to the the large slab, fill the burn parts w/ colored epoxy and did flood coat over top.

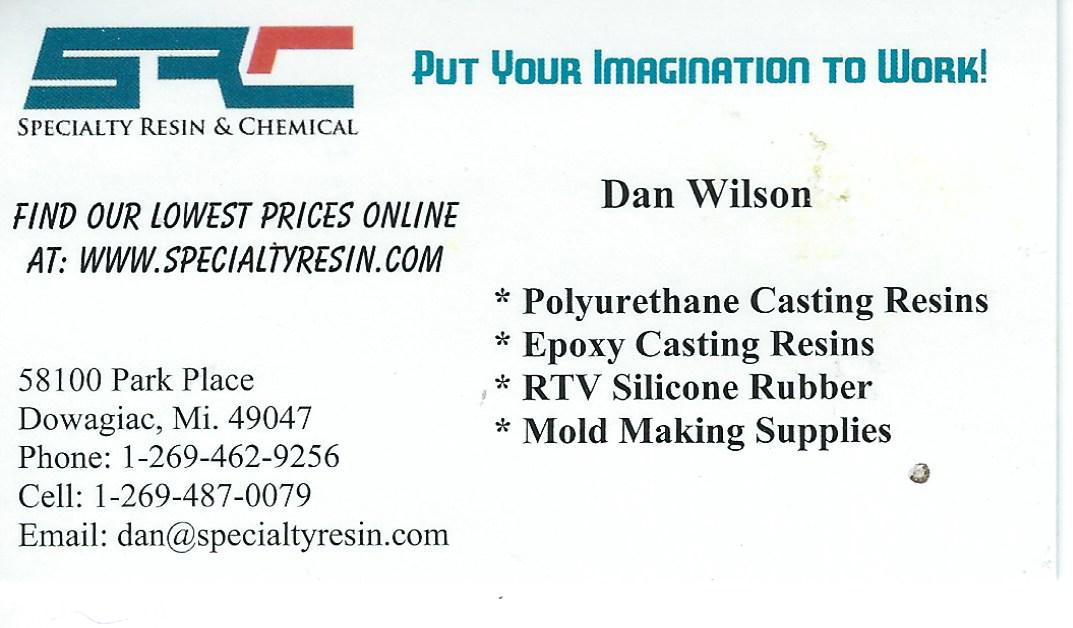

I found mine here. It really does help if you have some way to pull a small vacuum on your mixing cup at least, however, I did not do that and got decent results. Many people use a hair dryer to force the bubbles out if they have them. Check out the site shown in the JPEG. They also have various colorants.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.