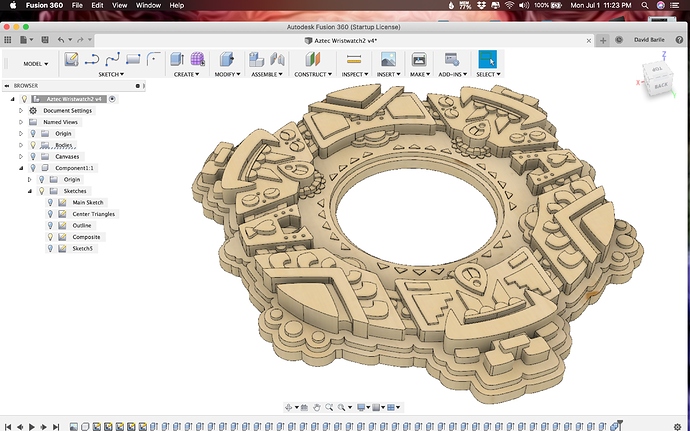

I recently carved this 28" x 25" x 2" art piece out of poplar on my Shapeoko XXL. It took a total of about 10 hours on the machine, using a 3/4" roughing end mill, a 1/4" for intermediate adaptive passes, and finishing off the details with a 1/8" downcut end mill - then a 1/4" Vee bit for some engraved details. I did some preliminary sanding, but am waiting to get my Dremel tool back from a friend to really clean up the edges and then I estimate 3-5 hours of hand sanding to really clean it up.

I must add that using downcut end mills has saved me hours on sanding and prevents a lot of chipping too… If you haven’t tried them, I highly recommend them!

Another note on my process is that I have begun using smaller stepdowns lately: usually .07" to - .09". Of course this increases cutting time, but it tends to give cleaner finishes and less chipping. Most importantly, it gives me peace of mind, not constantly listening for an abrasive sound when the machine cuts an unexpectedly deep or aggressive section.

8 Likes

Did you have any issues with wood warping?

I always seem to have warping issues when removing large amount of material…

May not have been as big of a deal with it being 2" thick. Did you make sure the wood was at equilibrium moisture? I think that’s always my issue… I cut it before it’s fully dried. I can’t always wait years for it to fully dry though

Actually, yes… even before carving. The wood I had bought was 14.5" wide, and the wood store shaved it to an even height to remove any warping. I brought it home and clamped and glued two pieces together to make one 29" x 29" block. I was nice and square, and I set it on the machine on Thursday, planning to carve it after the weekend. When I came back on Monday, it was quite warped. So I wound up just screwing it to the wasteboard at the four corners. That seemed to do the trick.

How bad is the final part after you un-clamped it?

To be honest, I’m not 100% sure. I haven’t put it against a flat wall yet. It was only about 1/4" or less of warpage when it was on the wasteboard. I doubt it changed too much, as a lot of the thickness of the stock remains in the final piece.

By the way, a veteran woodworker friend of mine told me a tip for wood that is warped. Spray the concave side with water and set it in the sun, wet side up. The cells of wood absorb the water and expand. Sometimes it is enough to fully correct the warp, other times it only lessens it.

2 Likes