I’m am brand new to this so I’m sure I will sound quite ignorant. I purchased a Shapeoko 3 xxl from a buddy and I have got it all set up. I went to carve a simple test piece and each time I try it will act like it’s carving but the bit is not touching the workpiece. I have set my g code and I have a bit setter and it seams to zero out just fine and the bit setter seams to work. I’m sure there is something simple that I’m overlooking. Any suggestions ? Thank you…

Where is the origin set in your file?

Where and how are you setting zero relative to the stock?

See:

After you initialize are you Zeroing your X,Y & Z with the bit you are cutting with?

1 Like

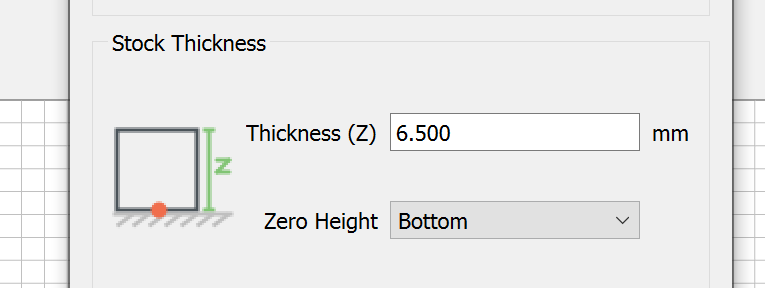

What design software are you using? In Carbide Create, you can get this behaviour if the design has Z Zero as bottom-of-stock, but on the machine you set Z Zero to be top-of-stock.

In Carbide Create, select the “Job Setup” icon to see where the Z Zero is.

Thanks for the help. It turns out when I did the initial set up I chose the Z-Plus instead of the HDZ.

1 Like

This topic was automatically closed after 30 days. New replies are no longer allowed.