@Julien

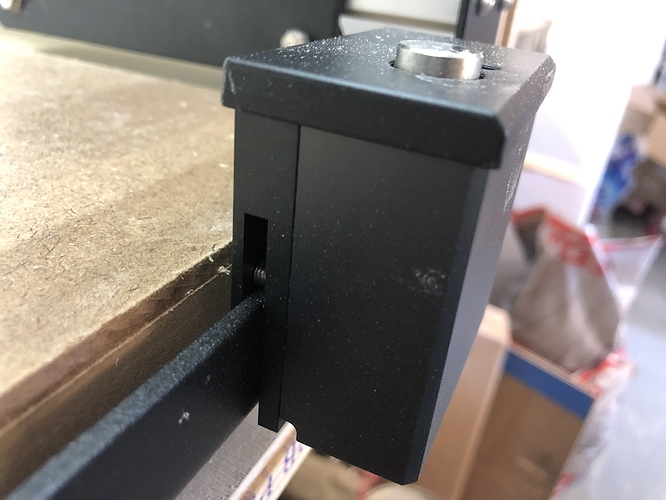

- Confirmed, the machine retracts to top of Z minus 5mm. I estimate about 10mm remaining between bit and button when I have about 1.25" of bit extended. This means the max I could achieve is less than 1.5" with the BitSetter. Could it be installed wrong? Pic below.

I recreated the problem. Here’s a link to the video: https://streamable.com/3uxide

Log results below. The order of operations here was initialize, probe fail, reinitialize, another probe fail.

N0 M5

ok

N0 G4P0.005

ok

N0 G4P0.005

ok

$h

ok

N0 G4P0.005

ok

N0 M5

ok

N0 G4P0.005

ok

N0 M5

ok

N0 G4P0.25

ok

N0G0Z-5.0000

ok

N0G0X-210.0000Y-400.0000

ok

N0 G4P0.005

ok

N0 G4P0.005

ok

N0 M5

ok

N0G0Z-5.0000

ok

N0G0X-3.0000Y-402.7750Z-5.0000

ok

N0G0Z-15.0000

ok

N0G38.2Z-155.0000F800.0

ALARM:4

GRBL_RESET

ok

Grbl 1.1f [’$’ for help]

[MSG:’$H’|’$X’ to unlock]

$X

[MSG:Caution: Unlocked]

ok

N0 G4P0.005

ok

G92.1

ok

G54

ok

G10L2P1X0Y0Z0

ok

G21

ok

G49

ok

G90

ok

$G

[GC:G0 G54 G17 G21 G90 G94 M5 M9 M56 T0 F0 S0]

ok

$#

[G54:0.000,0.000,0.000]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:0.000,0.000,0.000]

[G30:0.000,0.000,0.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

ok

N0 G4P0.005

ok

N0 M5

ok

G92.1

ok

G54

ok

G10L2P1X0Y0Z0

ok

G21

ok

G49

ok

G90

ok

$G

[GC:G0 G54 G17 G21 G90 G94 M5 M9 M56 T0 F0 S0]

ok

$#

[G54:0.000,0.000,0.000]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:0.000,0.000,0.000]

[G30:0.000,0.000,0.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

ok

N0 G4P0.005

ok

M56P1

ok

$$

$0=10

$1=255

$2=0

$3=6

$4=0

$5=0

$6=0

$10=255

$11=0.020

$12=0.010

$13=0

$20=0

$21=0

$22=1

$23=0

$24=100.000

$25=2000.000

$26=25

$27=3.000

$30=1000

$31=0

$32=0

$100=40.000

$101=40.000

$102=40.000

$110=10000.000

$111=10000.000

$112=5000.000

$120=500.000

$121=500.000

$122=400.000

$130=845.000

$131=850.000

$132=100.000

ok

N0 M5

ok

N0 G4P0.005

ok

N0 G4P0.005

ok

$h

ok

N0 G4P0.005

ok

N0 M5

ok

N0 G4P0.005

ok

N0 M5

ok

N0 G4P0.25

ok

N0G0Z-5.0000

ok

N0G0X-210.0000Y-400.0000

ok

N0 G4P0.005

ok

N0 G4P0.005

ok

N0 M5

ok

N0G0Z-5.0000

ok

N0G0X-3.0000Y-402.7750Z-5.0000

ok

N0G0Z-15.0000

ok

N0G38.2Z-155.0000F800.0

ALARM:4

GRBL_RESET

ok

Grbl 1.1f [’$’ for help]

[MSG:’$H’|’$X’ to unlock]

$X

[MSG:Caution: Unlocked]

ok

N0 G4P0.005

ok

G92.1

ok

G54

ok

G10L2P1X0Y0Z0

ok

G21

ok

G49

ok

G90

ok

$G

[GC:G0 G54 G17 G21 G90 G94 M5 M9 M56 T0 F0 S0]

ok

$#

[G54:0.000,0.000,0.000]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:0.000,0.000,0.000]

[G30:0.000,0.000,0.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

ok

N0 G4P0.005

ok

N0 M5

ok

G92.1

ok

G54

ok

G10L2P1X0Y0Z0

ok

G21

ok

G49

ok

G90

ok

$G

[GC:G0 G54 G17 G21 G90 G94 M5 M9 M56 T0 F0 S0]

ok

$#

[G54:0.000,0.000,0.000]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:0.000,0.000,0.000]

[G30:0.000,0.000,0.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

ok

N0 G4P0.005

ok

M56P1

ok

$$

$0=10

$1=255

$2=0

$3=6

$4=0

$5=0

$6=0

$10=255

$11=0.020

$12=0.010

$13=0

$20=0

$21=0

$22=1

$23=0

$24=100.000

$25=2000.000

$26=25

$27=3.000

$30=1000

$31=0

$32=0

$100=40.000

$101=40.000

$102=40.000

$110=10000.000

$111=10000.000

$112=5000.000

$120=500.000

$121=500.000

$122=400.000

$130=845.000

$131=850.000

$132=100.000

ok