I have a Shapeoko 3 xl, with a Z plus and Bitsetter. I was investigating how high I could raise my router as I as planning to machine a thick piece of stock. I initialised it and the z plus hit the end stop. Now when I attempt to use the Bitsetter the bit travels down about 10mm and stops and gives me a probing error.

It initialises fine and i can cut jobs without the Bitsetter with no problem. And I have no z height zero issues. Any suggestions?

Is this repeatable or did it just happen the one time you crashed the Z?

Anytime you crash, you should re-home.

It is repeatable. I have initialised numerous time since and cut a few jobs.

Do you have a probe, bitZero?

Yes I do.

(I have to add these extra characters to make it up to twenty for it to post. please ignore)

Too late. I read it. ![]()

Any chance you’re probe is making a connection? Does the probe work?

If you know how to open the log, can you paste the output here?

Edit: Looking for same thing as @fenrus. I didn’t realize Motion showed the probe pin status in the GUI.

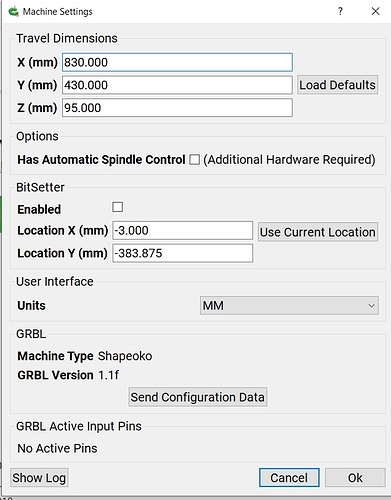

can you turn on your machine, start carbide motion, and go to the settings screen (the sprocket at the right top)

that screen shows the “live” view of all the X/y/z limit switches but also the probe…

you can live see if any of these trigger (and when they untrigger)…

on that screen, can you check that if you hit your bitzero with the clip, you see the probe signal show up, and once that part is known to work, push the button on the bitsetter… that should also show the same probe signal…

(and if nothing is touched, it should obviously NOT show that signal. once I had accidentally my clip touch my bitzero and that broke everything with the bitsetter since they share connector)

I’ll check that out in a moment. Just having an essential cup of tea.

yes

the “No active pins” will change if you trigger the probe or the X/Y/Z limit switches

Interestingly, when I drive the Z axis down, it hits a limit switch about 10mm above my base board. Does that mean something slipped when I drove the z axis up and collided with the stepper motor?

Have you run a job since this started? Any chance you have it set for the belt Z?

Maybe a loose wire?

I have run jobs with no issue. If i wasn’t using a 19mm supplementary base board I imagine I would have a problem with my depth of cut.

which limit switch does it hit?

When I say it hits a limit switch, I may be wrong. All I know is that the maximum downward travel of the Z axis is 10mm above the base board. It goes up to the maximum available height ok, just below the stepper motor.

It’s as if I’ve got the router mounted up higher than the usual position, but I don’t.

The LED on the Z axis at the top illuminates, and shows up as an active pin.

I can manually drive the bit down to the Bitsetter, and the LED illuminates and shows as an active pin.

the question then needs to be, which piece of metal is close…

can you take a picture of that right as it starts lighting up as you move it downwards?

Note that travel is limited by the Travel Dimensions set under Machine Settings.

Do you still have 10mm of rail left?

If so, increase by that amount.

I just thought I would uninstall and reinstall Carbide Motion. It worked! The end mill now moves down and connects with the Bitsetter. Yay!