Dooryard

December 3, 2021, 4:41am

1

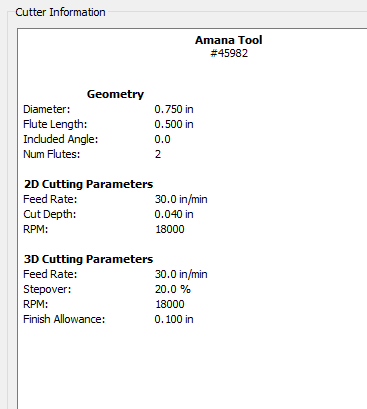

so I know bowl bits are not official supported as real bits in CC. so I followed some suggestions about setting it up as an End Mill.

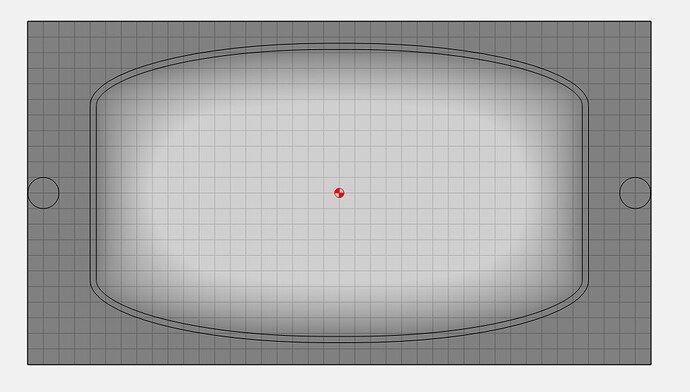

However I’d like to create a thin walled slopped valet tray.

Added a 0.1" inside offset and set up a double sided machining operation.

Now I think my interior slot discrepancy is coming from the lack of corners on my “end mill”

I guess for my next steps is I make the inner detail 0.2125" x 2 larger (which would be outside the outside) oi

WillAdams

December 3, 2021, 11:37am

2

Why not just finish w/ a smaller ball-nosed endmill?

If you add a bit of geometry which matches where the flat are should be it would be omitted from a finishing pass, and you should avoid scallops — or flip things: use the smaller ball-nosed endmill first, then switch to the bowl bit after and use it only for the flat-bottomed area.

Terry

December 26, 2021, 2:01am

3

Did you get this worked out?

I want to try the same thing and am setting up a 1"D x 1/2"H x 1/2" Shank Dish Carving bit from Rockler.

For this first attempt, I’d be happy with vertical side walls. I just can’t find appropriate feeds and speeds online for this bit.

I created a tool using your numbers above and will give it a go.

Thanks,

system

January 2, 2022, 4:42am

4

This topic was automatically closed after 30 days. New replies are no longer allowed.