I just got my second HDM up and running and it’s already missing steps. I was using extremely conservative feeds and speeds and somehow the machine goes off track and starts cutting the wrong stuff. I was also using an 1/8” endmill (which it should have no trouble breaking).I checked the motor couplings and everything was tight. I’m at a loss.

What material are you cutting?

At what feeds and speeds?

Note that you can’t reduce feeds and speeds so much that you cause the tool to rub rather than cut.

I was cutting G10 about 75 IPM at 20000 RPM .0625 DOC.

I usually cut it at 150 IPM 20000RPM .1” DOC.

Saw your ticket in the queue — we’ll have someone familiar w/ the HDM work through that with you there as soon as possible.

Will if you have any ideas I’m all ears! Another issue is, carbide motion keeps asking me to set the spindle speed.

Did you configure for having a VFD?

I guess I’m not familiar with that.

As far as the missing steps, I’m guessing it’s a binding issue. The pallet it came in on looked like it had a rough ride. I’ll loosen everything up and jog it a bit. I had to do this with my first machine.

It’s definitely the x axis that’s binding. Any suggestions on fixing it?

Fixed the X axis and now the Y is binding. Everything is well lubricated! I’ve loosened everything up, jogged the machine. No change.

I’ve checked couplings, ball screw bearings, motor bolts. I completely removed the hybrid table and loosened up one rail. Jogged it, no change. Then I loosened up both rails jogged, no change.

When removing the hybrid table, some of the extrusions were noticeably bent. Like the entire machine got twisted during shipping. Also the plastic brackets that were supposed to hold it to the pallet were all broken.

I have the machine sitting on a steel table with 1.5” of foam insulation on top of it.

Like I said originally, this is my second HDM. I had similar problems with my first machine but, I was able to fix those. I was very hesitant about purchasing a second machine because of all the problems my first one had. Definitely a huge disappointment to spend $5k+ on something that is supposed to be ready to go!

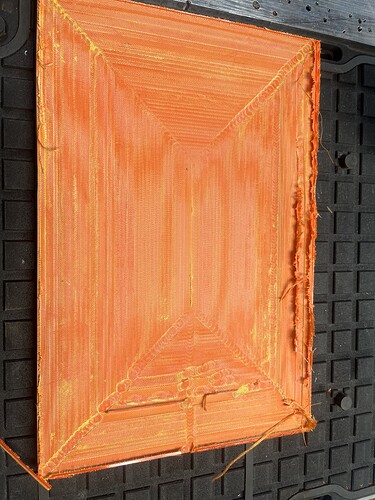

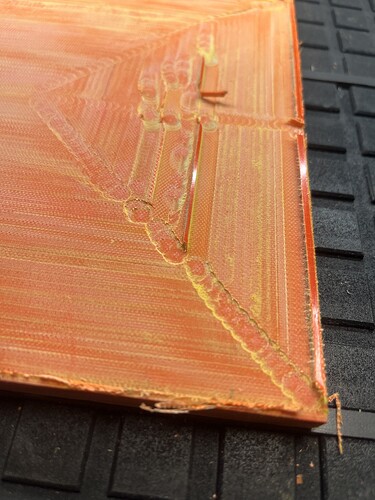

I’ve been running the machine hoping it just needs break itself in. Well yesterday the five bolts that hold the gantry to the y axis came loose and jammed themselves against the shroud on the left y axis.

I didn’t mean to upload that first picture

Any resolution on this? Mine is doing the same thing and not reflecting correct programmed RPM. HDM is selected everywhere it can be in CC and CM. I’m not clear where VFD can be selected in the new software.

I also just received my HDM and identified numerous hardware issues upon arrival, which I am still working through to determine what I can resolve on my own.

All of the 3D printed shipping clips were broken. It was clearly dropped.

I am missing several parts including the included tools.

Numerous machine screws were loose. Two were clearly the wrong type for the hole (internal hex vs countersunk hex).

One of the spoil boards is warped. When I removed it, it became clear the warping was caused by a very loose machine screw protruding and the assembler just cranking the spoil board down on top of it.

Tha machine is way out of tram and I’m not sure that’s the only xyz problem yet.

The resolution for this is to contact support@carbide3d.com and work with the folks there to resolve these issues.

I had to change it in the program files. I found an older post that had the correct steps to follow.

I’m extremely sorry that you’re dealing with the same issues because I know how frustrating it is. I asked the “support” guys if they had a bunch of problems with the HDM and they told me I was the only person since they updated the frame. The 30 day return policy is utter bs as well! Once you use the machine its yours forever! Mine is still sitting there not being used.

A word of caution, put some locktite on your spindle mount! My spindle almost fell completely off the last time i used it.

Let me know if you get it going, good luck.

This topic was automatically closed after 30 days. New replies are no longer allowed.