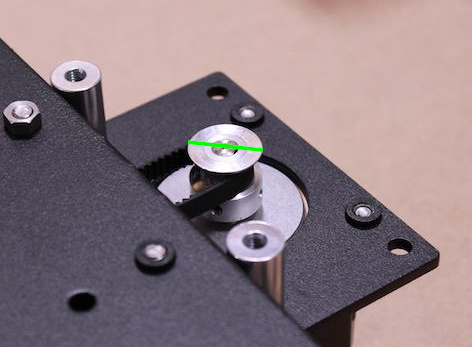

It’s easy to overlook a set screw issue. One possible way to double-check them is drawing a straight line across the pulley and shaft (with a marker), like so,

then cutting the “O” with the issue, and checking whether the pulley and shaft are still perfectly aligned then.

Also, you may want to try cutting straight horizontal and vertical lines. We had a thread recently that turned out to be a problem of geometry of a V-wheel, even though everything was nice and tight. I’m not saying this is the same issue, but cutting straight lines could provide additional hints.