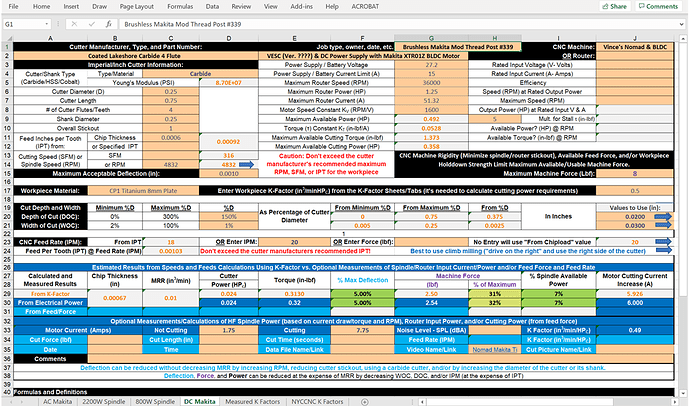

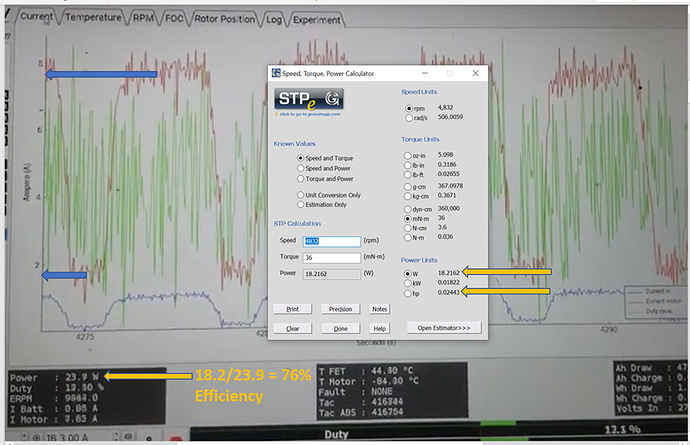

OOPS - I discovered some errors in the recently posted SFPF workbook’s “DC Makita” Speadsheet. Here’s what the corrected version looks for your “Nomad Makita VESC Titanium” video.

Using cutting current increase is the most accurate measure of cutting torque/force and power because it’s directly proportional to torque and isn’t impacted by inefficiencies.