Yay, and now it’s less like Brie ![]()

Just added vbus_voltage to the data output so I can see if that drops.

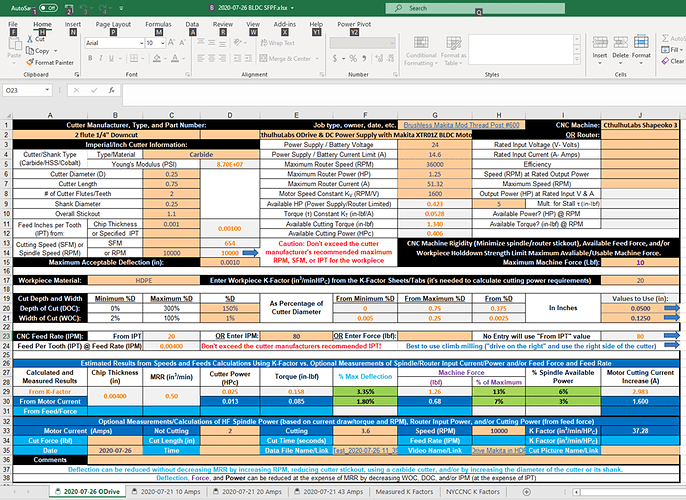

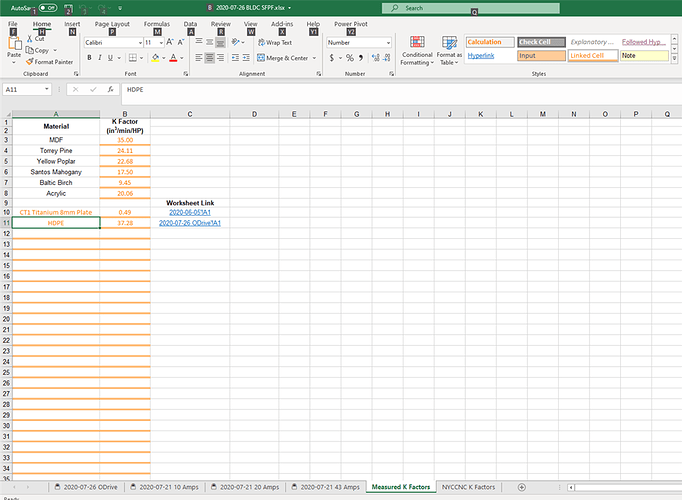

As shown below, your data indicates a K Factor of 37 ci-in. / HP / min. So I entered it on the SFPF spreadsheet for HDPE. Your and @Vince.Fab’s BLDC data should provide quite accurate K Factors for speeds and feeds calculations. A more aggressive cut would probably be more accurate though.

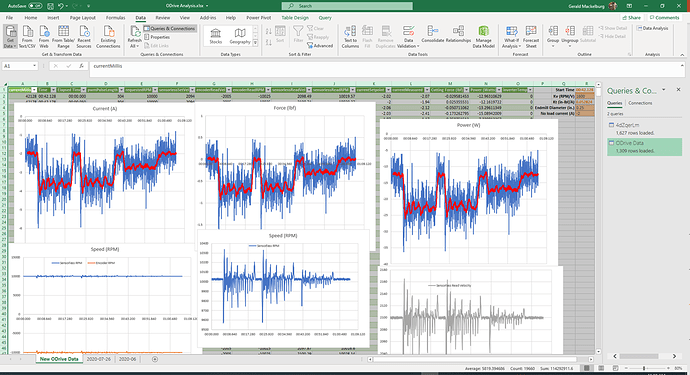

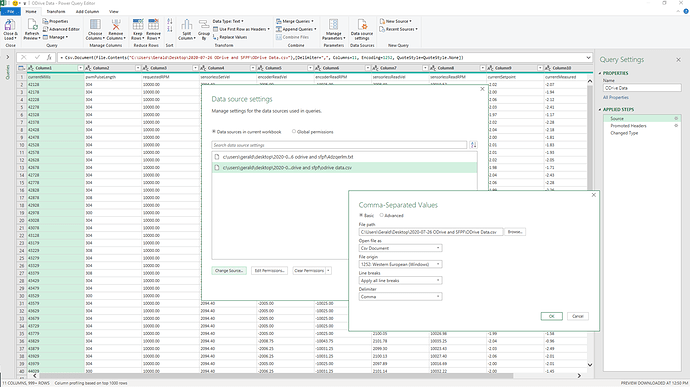

Here’s what your ODrive data looks like:

I can’t figure out how to prevent Excel from using absolute (rather than relative) data queries, so you’ll probably have to edit the source (and name if you like) to load new data.

Here’s everything 2020-07-26 ODrive and SFPF.zip (2.2 MB)

This looks like really useful data, there’s a lot less in the way of fudge factor for inefficiency or power factor here getting power out compared to the VFD spindles.

Since torque is proportional to current and power is the product of speed and torque, there is no fudge factor! ![]()

I cannot help but think of this.

Hmm. Be really neat to overlay these graphs on a video feed in real time.

Force and Power would be the most important IMO.

@CthulhuLabs, @Vince.Fab, other BLDC users, and @Julien (FYI)

I’ve been trying for over two years to come up with good K Factors to help understand and enable good speeds and feeds guidance and calculations. Although plenty seem to exist for metals, few-none are available for other materials. Furthermore, I believe that most-all of those for metals come from old machinist handbooks, so they may not be very accurate for modern high speed milling with the small diameter endmills commonly used by hobbyists. So, since you guys have ready access to the technology and capability, I’d be happy to analyze your data, provide feedback to you, and add your K Factor results to the SFPF workbook. That’s the “path of least resistance” for this old retired engineer’s OCD endeavor (unless of course you do it yourselves)! ![]()

Be more than happy to. You might think about setting up a Modkita yourself. I’d be happy to assist.

You might think about setting up a Modkita yourself. I’d be happy to assist.

But, I’d have to get my own CNC machine first since I was kind-of kicked off the shop’s (for “pushing it too hard”) ![]()

Well I am glad you stuck around. Offer still stands if you get a machine.

I have high hopes for BLDC routers since they are capable of high speeds (which reduce cutting forces) and likely have sufficient power for hobbyists - even with stock Shapeokos. So, I (and others) might take you up on that offer someday - but, baby steps first. Lets look at some more data? And, thanks for your input and insights about the VESC / RC hobbyist world - I had no clue about that stuff!

I’m a bit vague on all this black magic you’re doing but if I hook up a Nomad to VESC and get the data, would you be able to make similar calculations to what you’re doing here?

Is the motor in a Nomad brushless?

As far as I can tell, yeah. It’s got 3 wires and the McGillicutty looks an awful lot like an ESC.

If it is, you will want to go with the ODrive. While the VESC can control the motor sensorlessly, the code I wrote for the VESC requires a hall effect sensor. If the motor only has 3 wires, then it does not have a hall effect sensor. My ODrive code does not require the hall effect sensor. The VESC code is also not complete and needs someone familiar with Arduino coding to take it the last 5%. @Vince.Fab is currently having to manually adjust the duty cycle in order to get the RPM he is after. Plus the way I had to code the VESC arduino sketch there is no direct feed back from the VESC (thus why a hall sensor is needed). This is why Vince is having to setup the built in VESC logging to a CSV file through their tool.

The VESC code is also not complete and needs someone familiar with Arduino coding to take it the last 5%

Is that just to enable software speed control?

Yes. The VESC needs to be configured to take PPM input and adjust the duty cycle accordingly. The arduino then needs to have the PID controller setup to take the RPM from the hall sensor as the input, the requested RPM from the Carbide board as the set point, and adjust the PPM signal with the output. This was where I left off when I moved to the ODrive.

So if @Moded1952 is willing to manually set speed, he could use a VESC to generate CSV performance data - like @Vince.Fab has done? Can the “McGillicutty” do that or would he need a different ESC?