LiamN

July 24, 2020, 2:25am

582

I think this is Winston’s current link.

Attached is the slightly messed about with version I’ve currently got in Fusion in case you have any trouble with Winston’s library.

Carbide3D Tools.tools.zip (4.2 KB)

edit - I’m cutting wood and plastics, I wouldn’t even think about those feeds and speeds for metal.

1 Like

CthulhuLabs

July 24, 2020, 2:32am

583

Thanks

LiamN

July 24, 2020, 2:37am

584

Just to check…

Your Modkita is spinning in the correct direction? Sharp faces first?

If your spindle runs backwards at 20k RPM you do get some cutting effect but smoke not chips, I was careless one day rewiring my spindle to the VFD and didn’t check properly, the instant smoke told me to press the big red switch and figure out where I’d been a muppet.

5 Likes

CthulhuLabs

July 24, 2020, 4:02am

585

5 Likes

LiamN

July 24, 2020, 12:48pm

587

Ooops

Well, nothing that swapping a couple of wires around won’t fix.

2 Likes

CthulhuLabs

July 24, 2020, 1:08pm

588

I just changed the direction in the ODrive config.

I’m just wondering how dull my end mills are from this.

1 Like

LiamN

July 24, 2020, 1:11pm

589

Depends how long they were running backwards and how hot they got.

I used some tool cleaner and a brass wire brush on the unlucky 1/4" bit from mine to get the resin goo off it and it seemed no blunter than it was before.

1 Like

LiamN

July 24, 2020, 1:35pm

590

In the meantime, you could change your avatar to Arthur Brown

1 Like

CthulhuLabs

July 24, 2020, 3:10pm

591

Apparently a soak in 50/50 laundry soap and water for 30 minutes can get the residue off.

1 Like

CthulhuLabs

July 24, 2020, 5:24pm

592

Seems to have loosened the crud, but might need a brass brush still.

LiamN

July 24, 2020, 6:18pm

593

Either that or a bit of wood to cut…

2 Likes

CthulhuLabs

July 25, 2020, 7:02pm

594

So this explains why my HDPE cutting boards weren’t cutting properly

4 Likes

LiamN

July 25, 2020, 8:00pm

595

Yep, melting your way through them backwards is likely to make them a little stringy

1 Like

@CthulhuLabs Maybe you could request that this thread be reopened?

I had one of those moments earlier where I did something pretty dumb.

I had my £100 pro tram tram mounted in my Shapeoko with metal bed and HDZ. I then pressed the Z jog without checking the movement distance in CNC JS. Effectively jamming the pro tram right into the metal bed…

My pro tram is now totally buggered, jammed down and not moving…

I’ve used it twice

Can’t wait to see your progress with the endmill spinning the right way!

3 Likes

CthulhuLabs

July 26, 2020, 3:46pm

597

Cutting HDPE with a endmill spinning the right direct:

@gmack Here is the data file:ODrive_Test_2020-07-26 11_39_02.zip (20.7 KB)

Some of the values are negative now because the spindle is going in the opposite direction. I will pass those through an ABS() function on the arduino in my next iteration.

If you could send me back the spreadsheet you are using to generate those graphs it would be really handy.

3 Likes

CthulhuLabs

July 26, 2020, 3:47pm

598

The surface finish is flawless. God I feel like an idiot. lol

2 Likes

gmack

July 26, 2020, 3:58pm

599

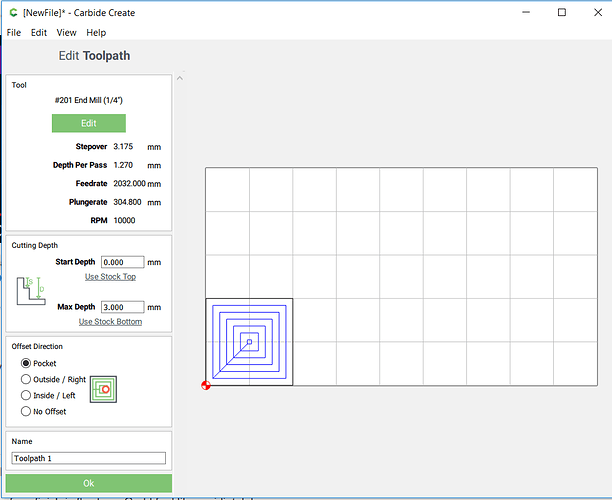

What were you doing? Endmill and stick-out, depth and width of cut, spindle speed, and feed rate?

CthulhuLabs

July 26, 2020, 4:27pm

600

Stick out was 28mm everything else was in here:

CthulhuLabs

July 26, 2020, 4:30pm

601

Whoops… actually no. It was not the #201 . It was a 1/4in 2 flute down cut endmill. I thought i had the #201 loaded though.

I wont be cutting metal till I move.

I wont be cutting metal till I move. …OMFG… You are right. It is running backwards.

…OMFG… You are right. It is running backwards.