I am not using an ADC. I am using interrupts on the arduino to measure the pulse width directly. I am not measuring the resulting voltage. The CM board and the Arduino are electrically isolated through one of these:

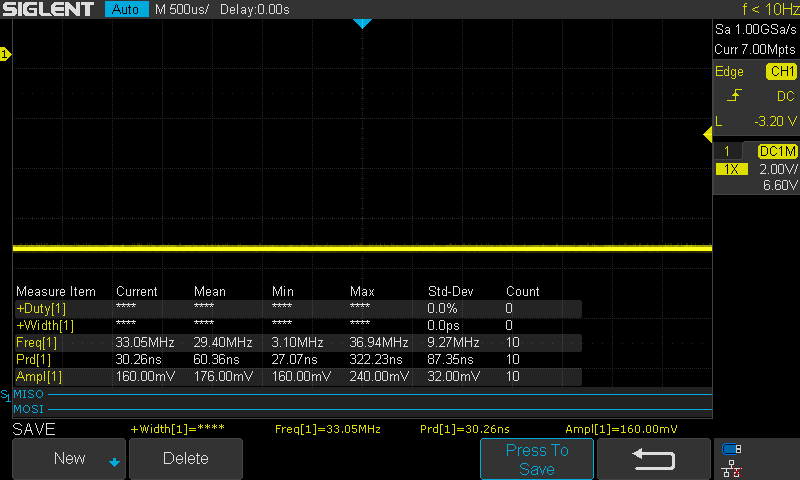

Well something’s up because the CM definitely shouldn’t output PWM when M5 is issued:

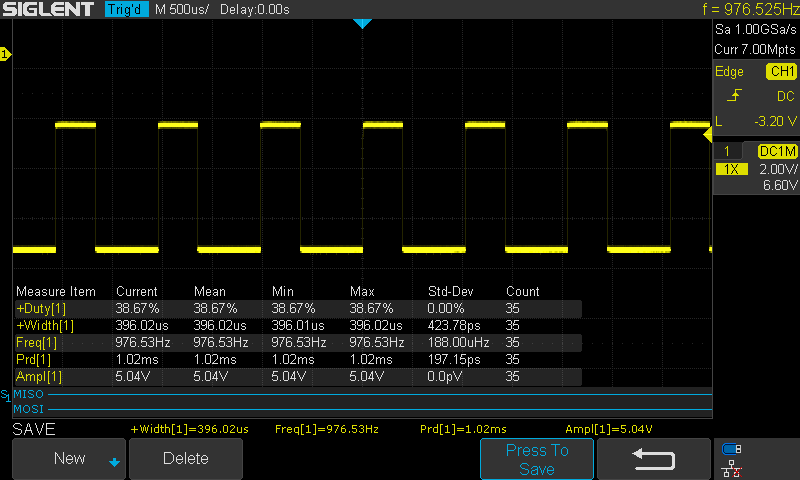

M3 S2000:

M3 S5000:

M5:

I might be totally off here but is it possible that your code is something like:

int pulse_width;

last_time = micros();

void interrupt() {

pulse_width = micros() - last_time;

}

void loop() {

Serial.print(pulse_width);

}

And since you’re not getting any pulses, the interrupt isn’t being triggered and you’re not updating the pulse width either?

That is possible, but I believe I already handled that situation. I’ll have to check when I get home.

Nice scope! Which Siglent is it?

I bought it as an SDS1104X-E but I hacked the firmware so now it’s essentially a SDS1204X-E.

I have seen that hack a bunch.

Maybe dumb questions, but does it reduce the sample rate (with anti-aliasing filters?) based on the selected time base and analog gain control before it samples? How many bits does it sample to?

I don’t know a whole lot about this either, I haven’t used oscilloscopes much.

Yes, I believe so but Siglent has a bunch of fancy magic that makes this a bit more complicated.

It has 8-bit vertical resolution.

It sounds like a fixed sample rate - which is displayed on the screen. Does that change with time-base changes?

It’s not a fixed sample rate. To eliminate all doubt, I’ll quote the manual:

The maximum sample rate of the oscilloscope is 2GSa/s. The actual sample rate of the oscilloscope is determined by the horizontal scale. Turn the Horizontal Scale Knob to adjust the sample rate.

If you use an outrunner BLDC motor you will get far more torque as you have more poles. It’s the main reason electric skateboards use them. They are easy to mount but it would need a particle filter cage of some sort. As the windings are exposed to airflow.

something like this with a flight controller hooked up to a good power supply would be a monster.

The speed can also be controlled by a simple servo tester hooked up to the ESC for those not looking to use computer software. It’s simply add power let the ESC arm and turn the dial/ potentiometer

You were spot on. The code I had to handle the fall time not updating did not make it into this version of my code. It is in the VESC version of my code. So now it is stopping properly.

That said, I just set the RPM to 35000. Current hit my software set current limit of 20A and RPM only got to 28k. Then I change the RPM to 2000. The sudden change caused the bus voltage to jump to 60V and my powersupply shutdown. Luckily it came back up. I thought the breaking resistor would soak that up. Need to check with the ODrive people.

This makes me think of another question: aside from already having a router or BLDC motor + spindle around, is there any advantage to a BLDC + ESC combo over a VFD + Spindle combo?

As a replacement for the Makita on a Shapeoko it would be absolutely awful. That motor has radial bearings not axial. As such plunging into materials would kill the bearings almost instantly. It also has way too low of a kV rating. 190kV * 24V = 4560 RPM.

As a replacement for the motor on the Nomad it would be great (assuming you could get it to fit). The Nomad has great bearings in its spindle and it has a 2.5 to 1 gear ratio so the 4560 RPM at the motor would translate to 11400 RPM at the end mill.

Do you have any smoothing caps on the input to the ODrive?

Those can help eat those short term transients, the problem with switching PSUs is that they can absorb very little back-EMF from the load, this is why the ancient toroidal + bridge rectifier + pile of caps is so popular with folks running big stepper controllers.

Change that from toroidal to Variac/autotransformer for high power, variable, and “bulletproof” power supply?

Nomad needs speed not torque!

After having access to as much speed or tq in a Nomad as possible, the conclusion was that it likes a combination of both. 20,000 rpm would be a nice sweet spot, which is also the new Nomad 3’s max rpm…

How much more powerful is the motor?